Resin composition for laser processing

A resin composition and laser processing technology, applied in the direction of thermoplastic polymer dielectric, printed circuit dielectric, coating, etc., can solve the cracking of resin composition, the resistance of plating chemical reagents, and the formation of alkali-developable plating. , The problems of laser processability and corrosion-resistant resin composition are not obtained, and the effect of improving laser processability and improving laser processability is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

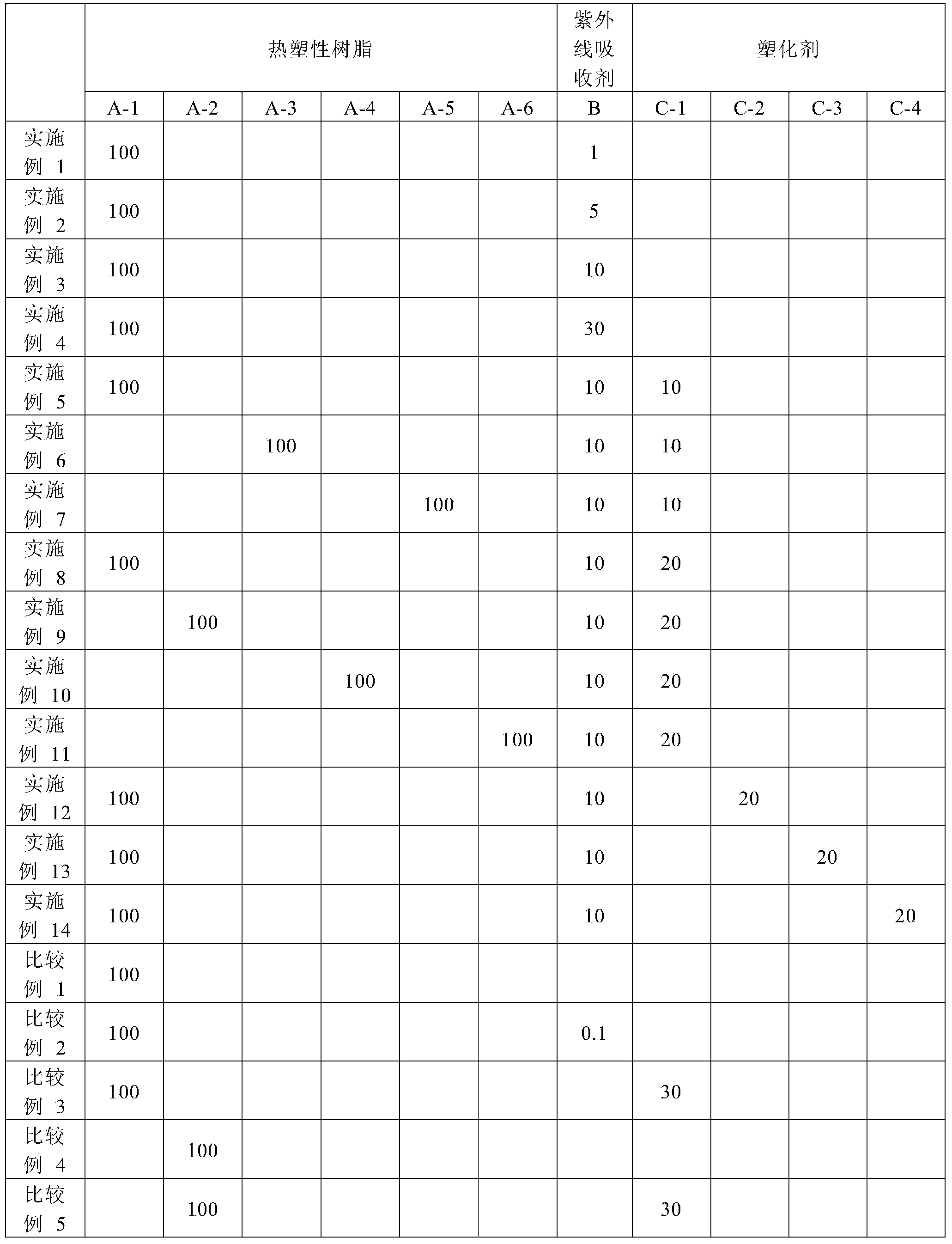

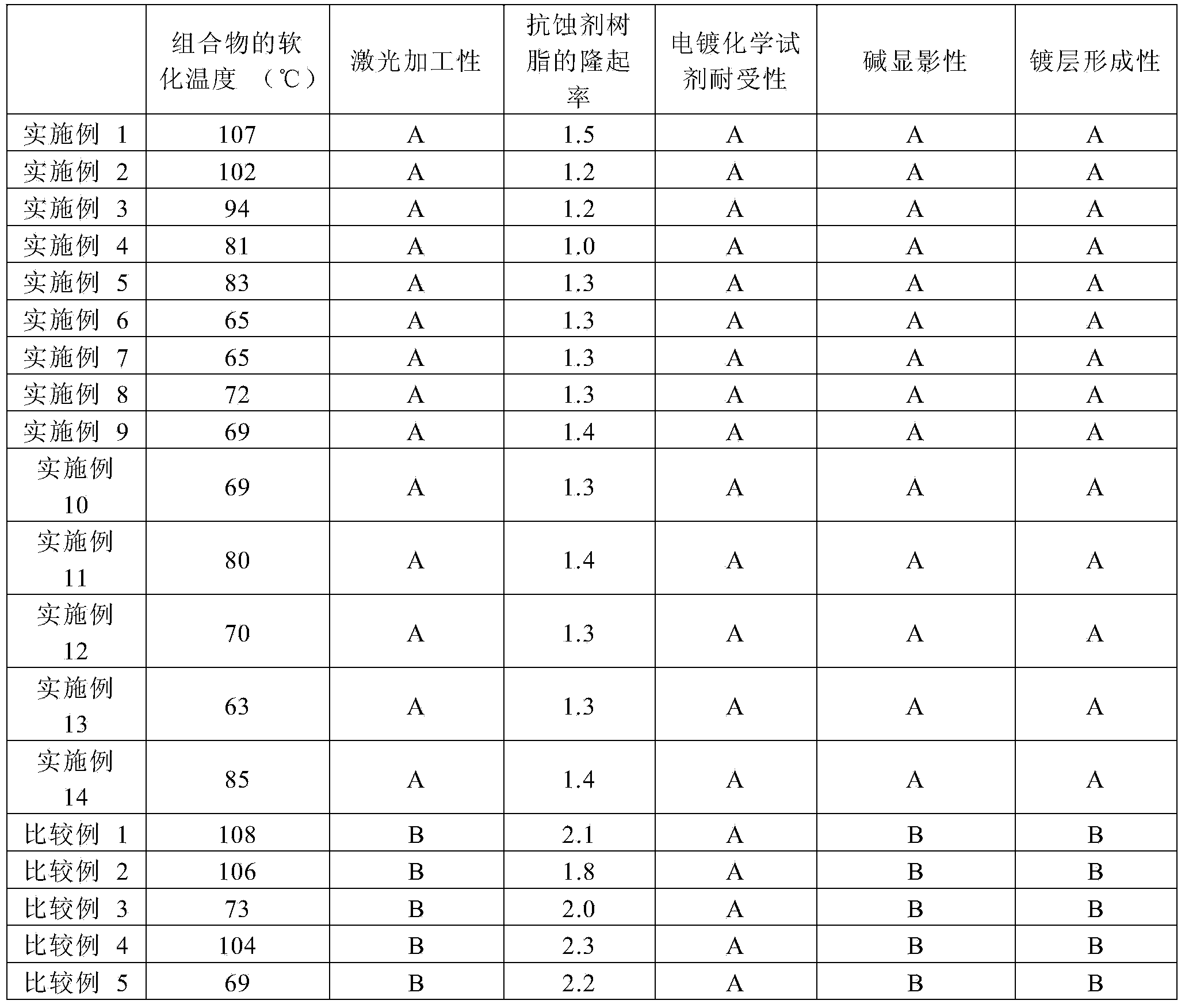

[0054] Although the present invention is described more specifically below by referring to Examples, it should not be construed that the present invention is limited to the following Examples. It should be noted that, hereinafter, the term "parts" means "parts by mass" unless otherwise specified.

Synthetic example

[0056] (Thermoplastic resin A-1)

[0057] In a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, a dropping device, and a nitrogen gas introduction tube, nitrogen gas was sealed, and then, 120 parts of methyl isobutyl ketone, 30 parts of isopropanol, 27 parts of acrylic acid were added , 55 parts of styrene, 18 parts of 2-ethylhexyl acrylate, and 2,2'-azobisisobutyronitrile (trade name: V-60, manufactured by Wako Pure Chemical Industries, Ltd. .manufacture). The above-mentioned contents were polymerized at 80° C. for 12 hours with stirring in a nitrogen stream to obtain a thermoplastic resin A-1. The obtained thermoplastic resin A-1 was found to have a weight average molecular weight of 30,000 (measured by GPC, the same below) and a softening temperature of 108° C. (measured by a flow tester, the same below).

[0058] (Thermoplastic resin A-2)

[0059] In a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, a dropping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com