Checkout equipment applied to laser head and corresponding laser head

A technology for testing equipment and laser heads, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing the accuracy of the laser processing process control process, unable to display the state parameters of the laser head, etc., and improve the effect of laser processing , avoid the effect of low process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

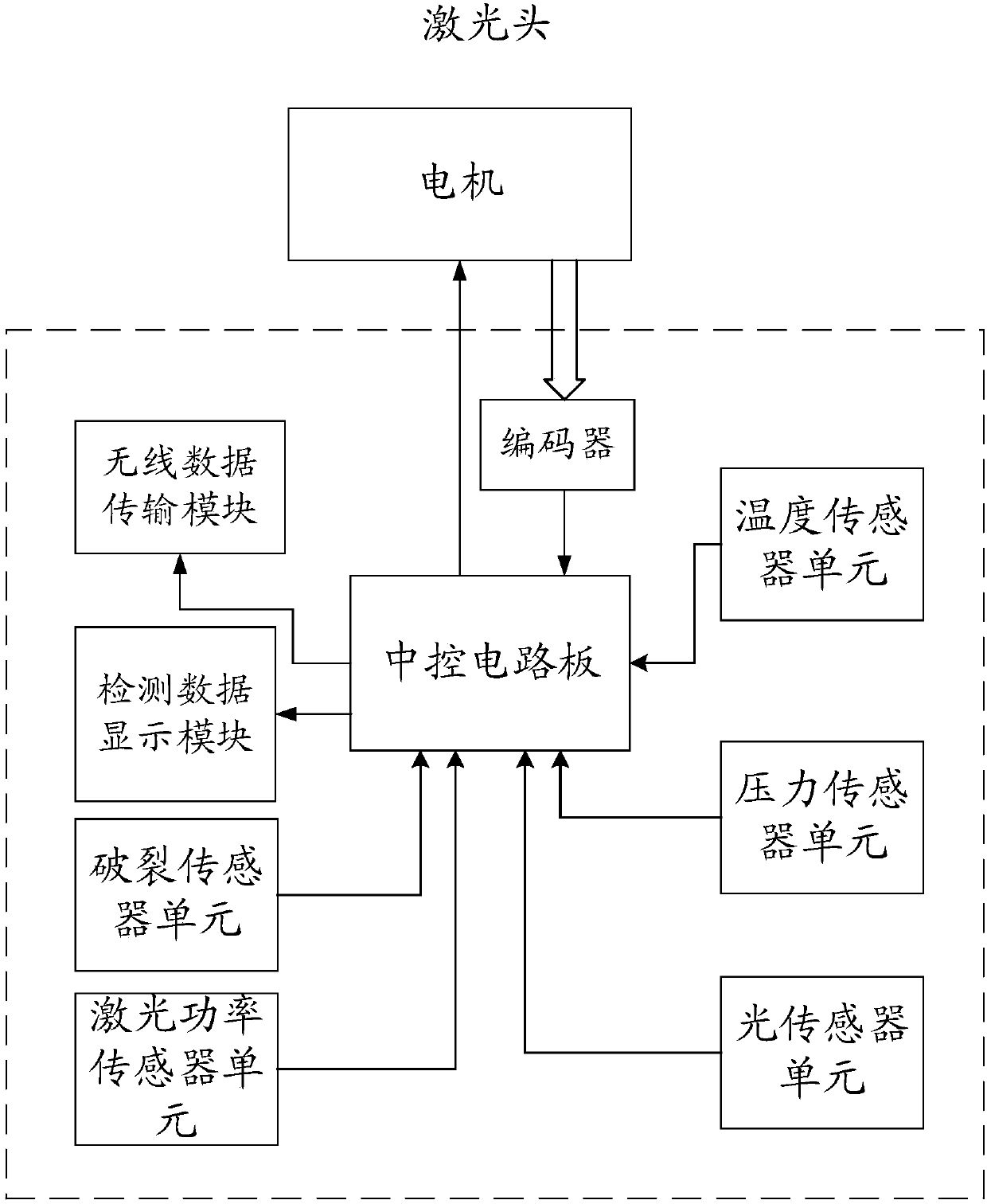

[0026] The detection equipment applied to the laser head, wherein the equipment includes:

[0027] The first data detection module is used to detect the parameters of the laser head and the equipment related to the laser head;

[0028] A detection data display module, configured to display various parameters detected by the first data detection module;

[0029] The control module is connected to the first data detection module and the detection data display module respectively, and is used to convert the various parameters detected by the first data detection module into the displayable parameters of the detection data display module. Each parameter is used to control each module in the laser head.

[0030] In the above embodiment, the first data detection module includes:

[0031] A temperature sensor u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com