Temperature humidity linkage type transformer cabinet

A substation and humidity technology, applied in the field of substation, can solve problems such as affecting the working stability, service life, affecting the reliability of internal equipment, fire, etc. Effects, effects with simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

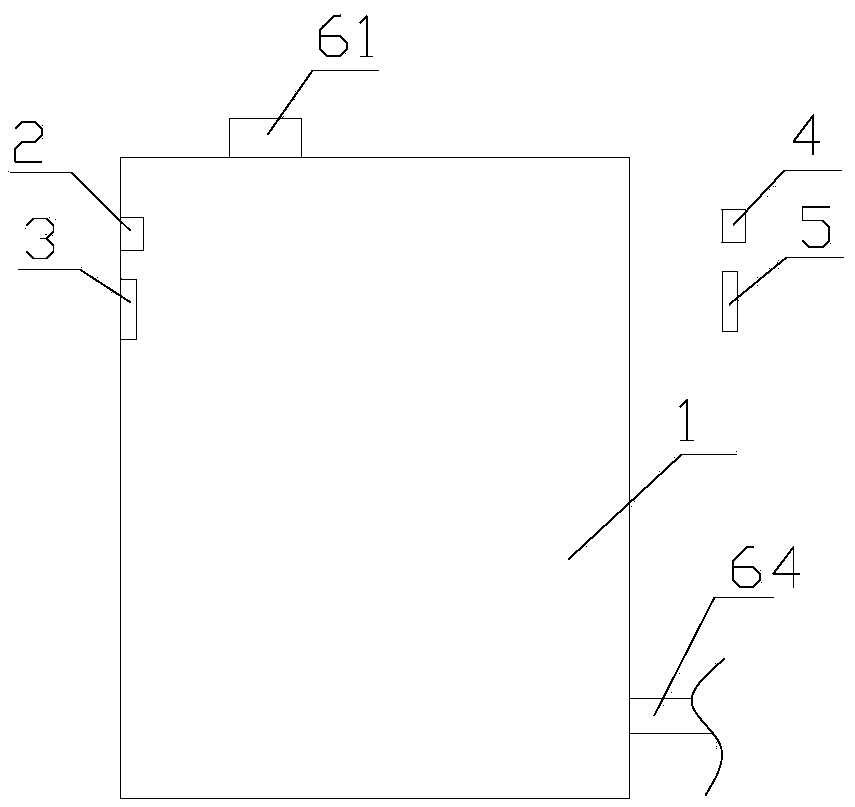

[0030] Such as figure 1 , figure 2 As shown, a temperature and humidity linkage type transformer cabinet proposed by the present invention includes: a cabinet body 1, a first temperature sensor 2, a second temperature sensor 3, a first humidity sensor 4, a second humidity sensor 5, an adjustment system and a control system module.

[0031] The first temperature sensor 2 and the first humidity sensor 4 are installed inside the cabinet 1 for detecting the temperature and humidity in the cabinet 1 respectively. The second temperature sensor 3 and the second humidity sensor 5 are installed outside the cabinet body 1 for detecting indoor temperature and humidity respectively.

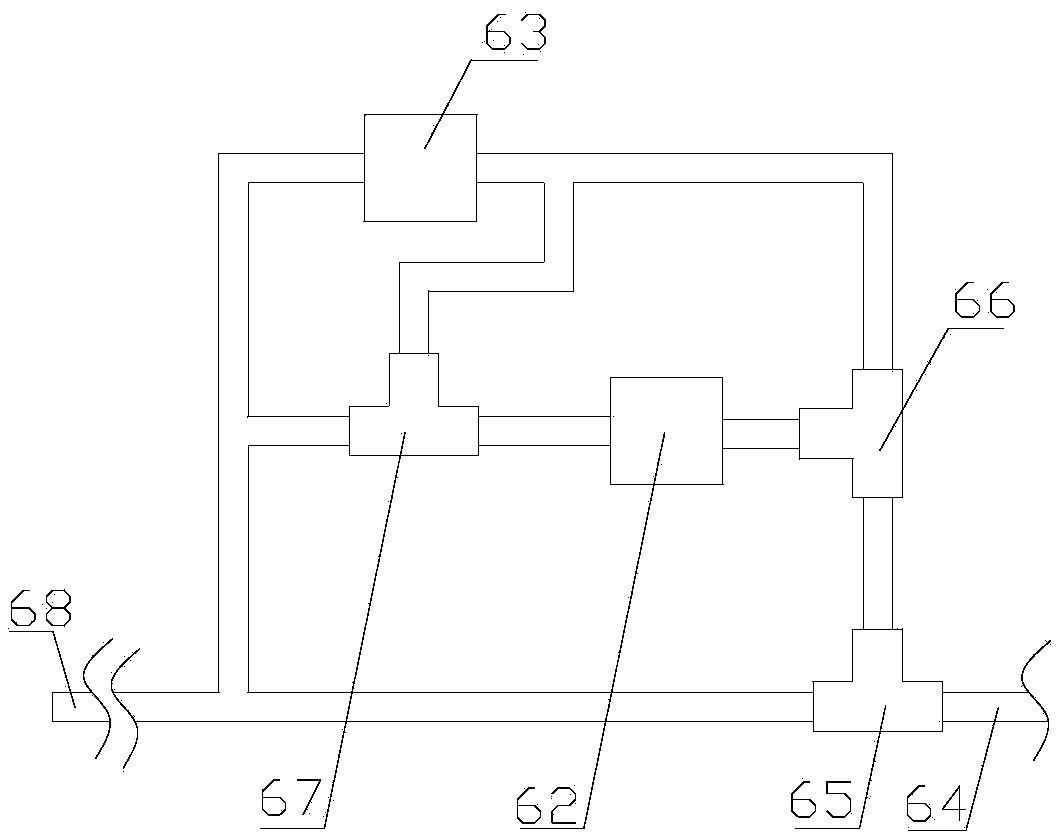

[0032] The conditioning system includes a ventilation structure 61 , an air delivery mechanism, a dehumidification device 62 and a cooling device 63 . The ventilation structure 61 is installed on the cabinet body 1 to discharge the air inside the cabinet body 1. Specifically, a ventilation fan or a throu...

Embodiment 2

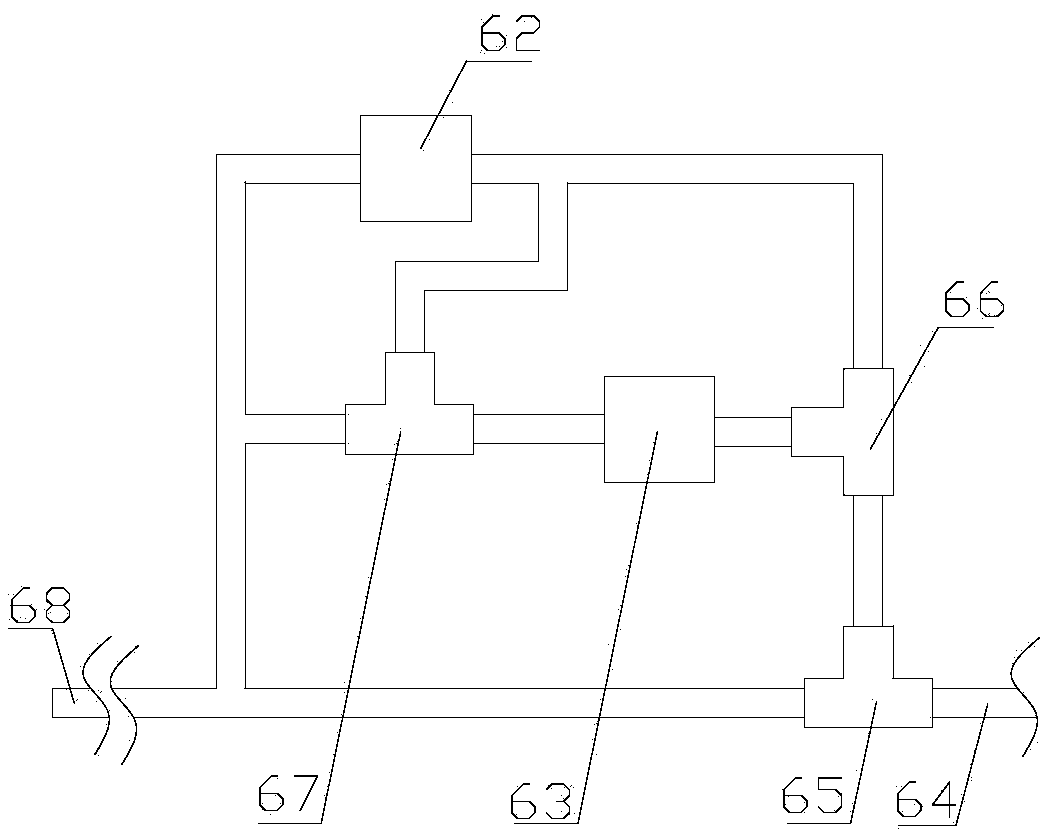

[0048] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the first output end of the second three-way valve 66 is connected to the input end of the cooling device 63, and its second output end is connected to the input end of the dehumidification device 62, and the output end of the cooling device 63 is connected to the input end of the cooling device 63. The output end is connected to the input end of the third three-way valve 67 , the first output end of the third three-way valve 67 is connected to the input end of the dehumidification device 62 , and the output end of the dehumidification device 62 is connected to the air outlet pipe 68 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com