Active rolling and transporting device of cables for submarine cable laying

A submarine cable, winding and conveying technology, applied in cable laying equipment, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of submarine cable damage, inability to achieve back-twisting, installation and disassembly difficulties, etc., to improve efficiency. and stability, strong promotion and application value, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

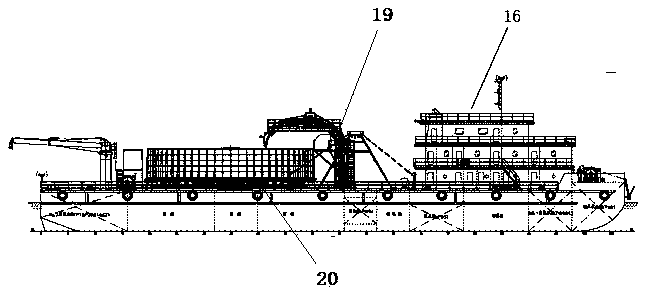

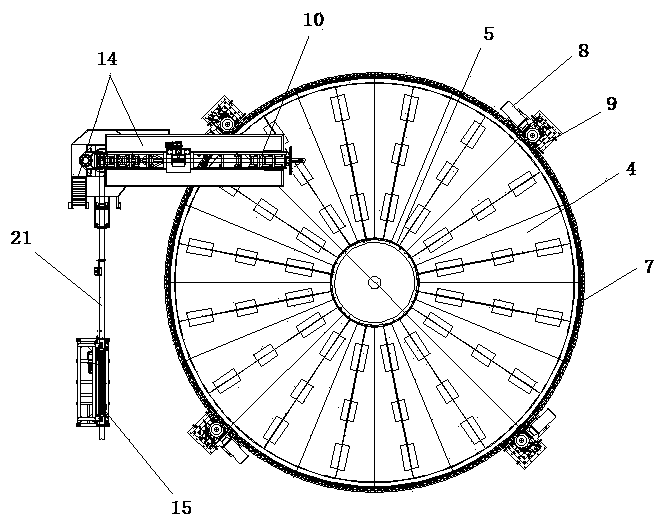

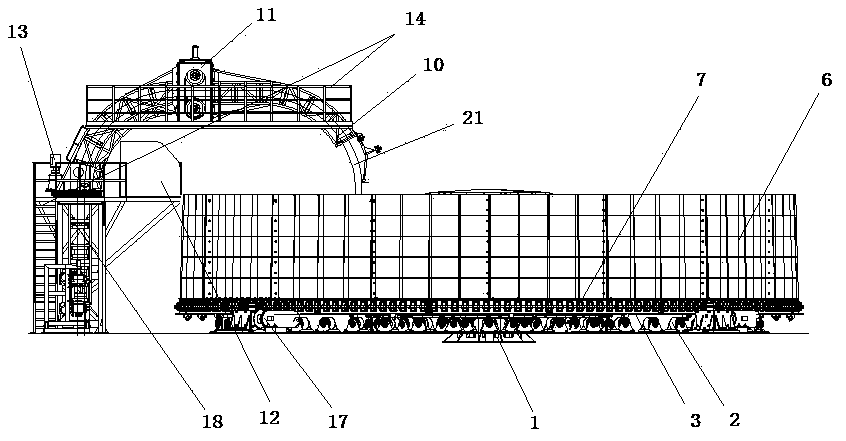

[0022] Such as figure 1 As shown, the cable active winding conveying device for submarine cable laying includes a horizontally placed circular cable tray 4 , a cable guiding device 19 for cable traction and guidance, and a console 12 .

[0023] In order to realize the planar active complete back-twisting goal of the submarine power cable 21 and reduce the various drawbacks of the traditional three-dimensional back-twist frame, the center of the cable tray 4 is provided with a slewing bearing 1 that can rotate around its own axis, and the slewing bearing 1 can be The rotating one is fixed on the deck of the submarine cable ship 16, and the bottom of the side of the cable tray 4 is fixedly connected with a drive chain 7 along the circumference. , the power drive device 17 is evenly arranged around the cable tray 4 at intervals of 90 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com