Seat cushion

A seat and cushion technology, applied in the lightweight field, can solve the problem of poor recycling performance of polyurethane foam, and achieve the effects of reducing processing costs, good creep resistance, and good seating feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

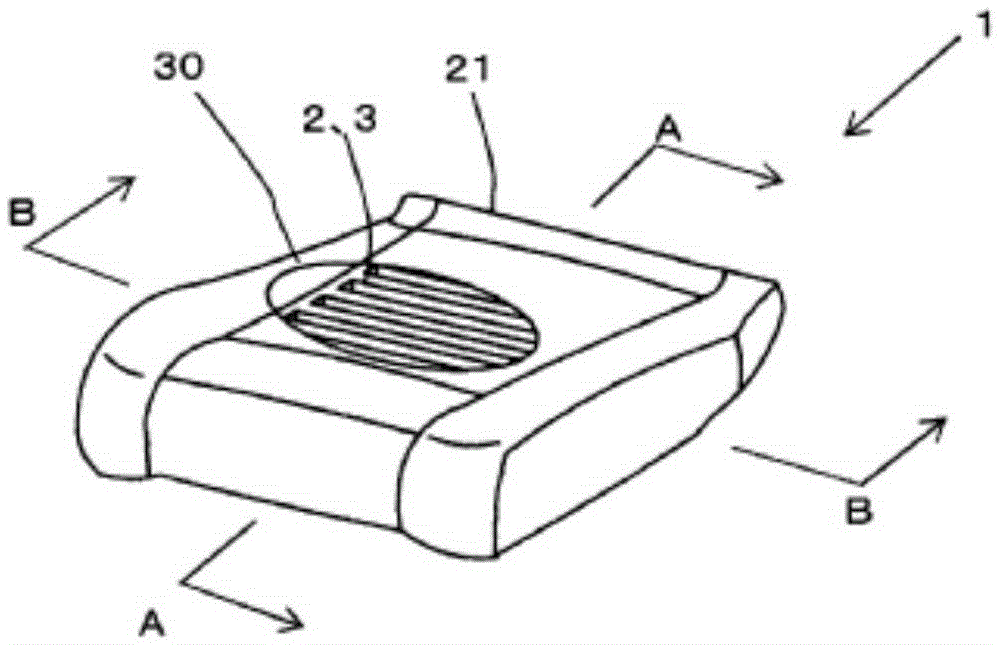

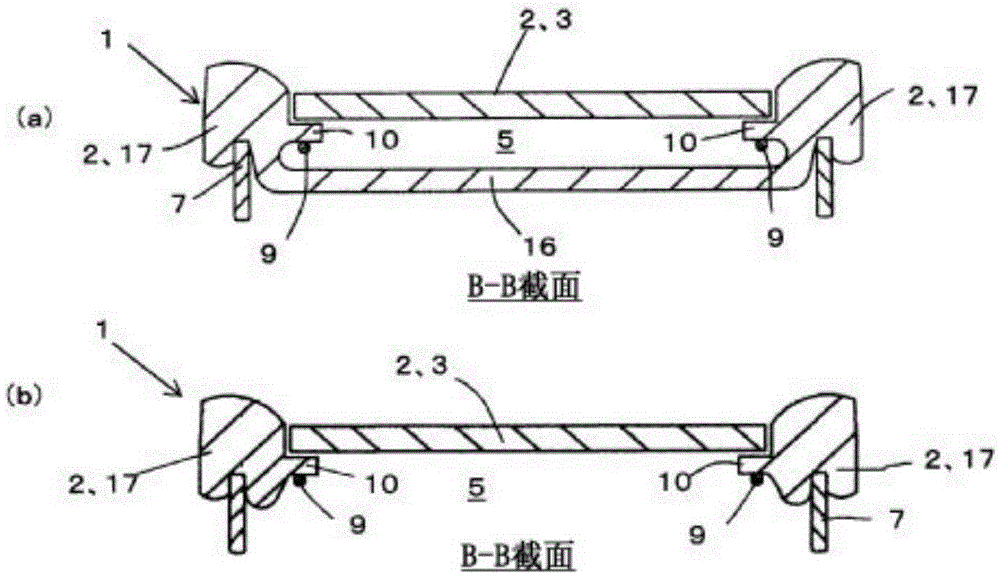

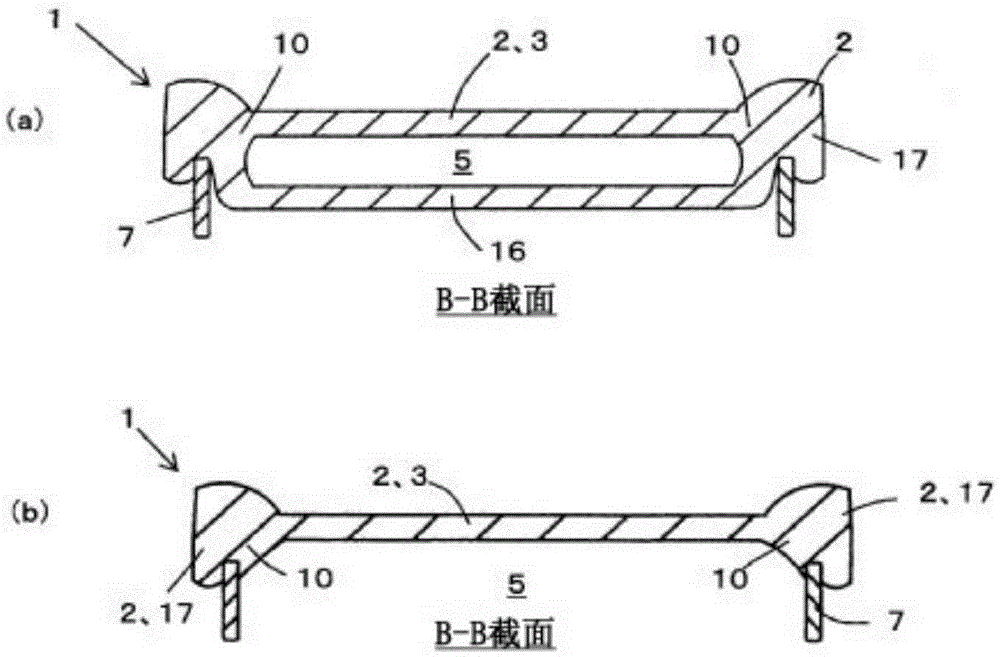

[0090] Hereinafter, an embodiment of the seat cushion 1 of the present invention will be described.

[0091] The seat cushion 1 of the present invention is a seat cushion 1 including a seat cushion 2 which is arranged to face each other with a predetermined interval and is formed around an upper edge portion of the seat cushion 2 . The edge-shaped member 10, and a plurality of independent synthetic resin foams with a deflection of 20 mm or more measured according to the method described in JISK7221-2:2006 and a load of 2 to 100 N when deflected by 20 mm The rod-shaped or plate-shaped support body 3 is mounted, embedded or fixed in such a way that the above-mentioned seat cushion 2 is supported at one point or at multiple points in the direction of erecting between the above-mentioned edge-shaped members 10. It is provided on the above-mentioned edge-shaped member 10 or integrally formed with the above-mentioned edge-shaped member 10, and the plurality of support bodies 3 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com