Spring mattress sponge side frame

A side frame and sponge technology, applied in the field of mattresses, can solve problems such as bonding and irreversible joints, and achieve the effect of ensuring normal rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

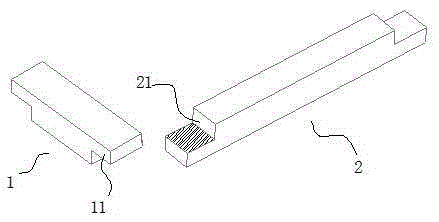

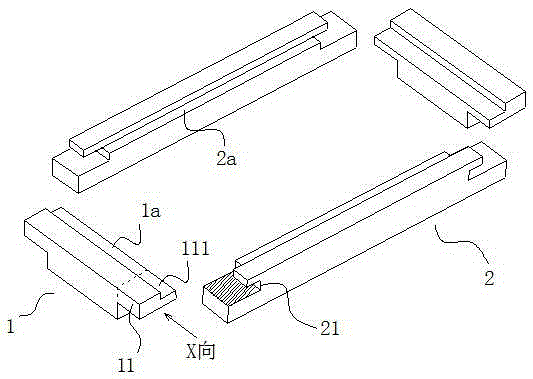

[0019] see Figure 2~3 ,

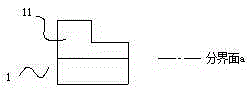

[0020] In each adjacent two sponge side panels A1 and sponge side panels B2, the end face top of the sponge side panel A1 has a protrusion 11 protruding along its long axis direction, the cross section of the protrusion 11 is stepped, and The horizontal step surface 111 of the stepped protrusion 11 (see Figure 4 ) is located on the inner side of the sponge side plate A1; the end surface of the sponge side plate B2 has a gap 21 that can just fit the protrusion; when the protrusion 11 of the sponge side plate A1 is embedded in the gap 21 of the sponge side plate B2, the stepped The contact between the lower surface of the lifter 11 and the sponge side panel B2 is a horizontal bonding surface (see figure 2 middle shaded part), the sponge side panel A1 and the sponge side panel B2 are fixed by adhesive bonding at the horizontal bonding surface.

[0021] In the above embodiment, if image 3 As shown, the stepped protrusion 11 is L-shaped with two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com