Dose adjustable syringe based on rotary inhalation

An adjustable and inhalation technology, applied in the field of syringes, can solve problems such as secondary damage to the injector, affect the injection effect of the injectee, and difficulty for beginners, so as to achieve free installation and disassembly, improve the flexibility of use, and improve the injection efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

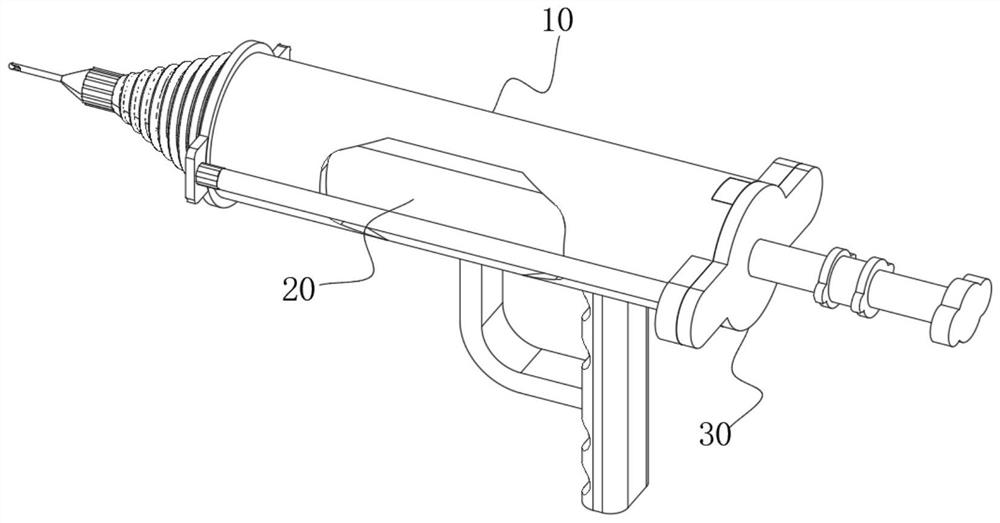

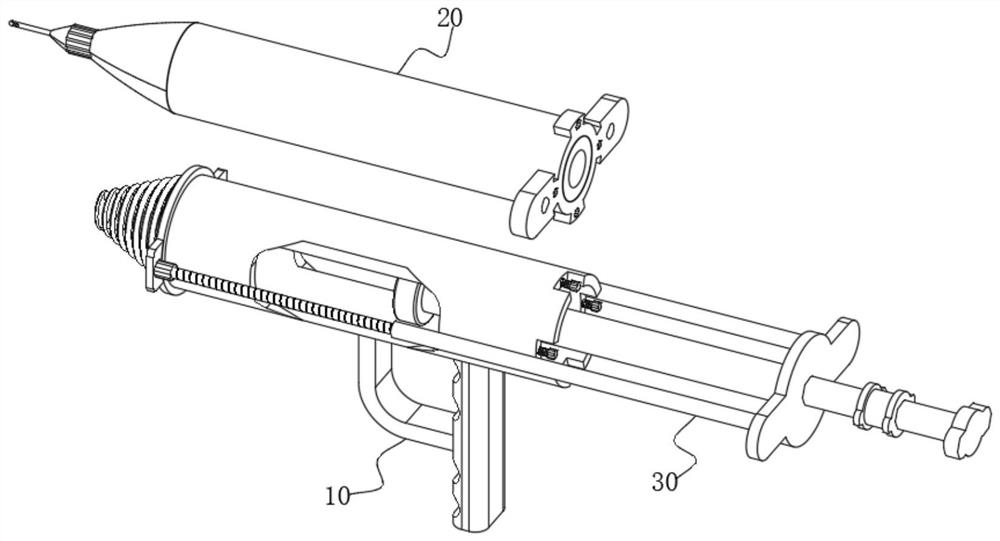

[0059] see Figure 1-Figure 11 As shown, the purpose of this embodiment is to provide a syringe with adjustable dose based on rotary inhalation, including a needle cover 10, a needle tube 20 installed at the inner end of the needle cover 10 and a push tube 30 installed at the inner end of the needle tube 20, the needle cover 10 Include at least:

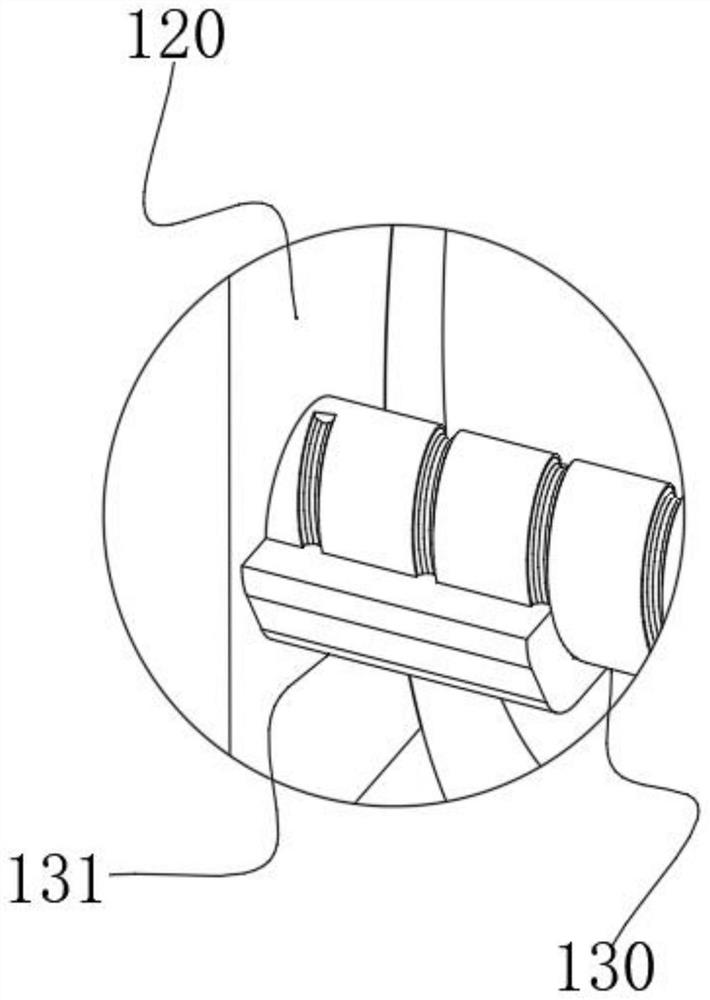

[0060]A snap ring 110, the snap ring 110 is arranged at the end of the needle sheath 10;

[0061] Baffle 120, a pair of baffles 120 are provided, and the two baffles 120 are respectively arranged on the left and right sides of the snap ring 110;

[0062] Scale rod 130, scale rod 130 is arranged on baffle plate 120 side, and scale rod 130 surface is provided with screw thread, and scale rod 130 surface is provided with scale line, and scale rod 130 is provided with scheduling block 131, and scheduling block 131 is threaded with scale rod 130. turn;

[0063] The inner end of the needle tube 20 is sleeved with the needle sheath 10. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com