Surface-curvature-based automatic path generation method for spraying robot

A spraying robot, surface curvature technology, applied in the direction of spraying device, etc., can solve the problem of lack of process algorithm of spraying robot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

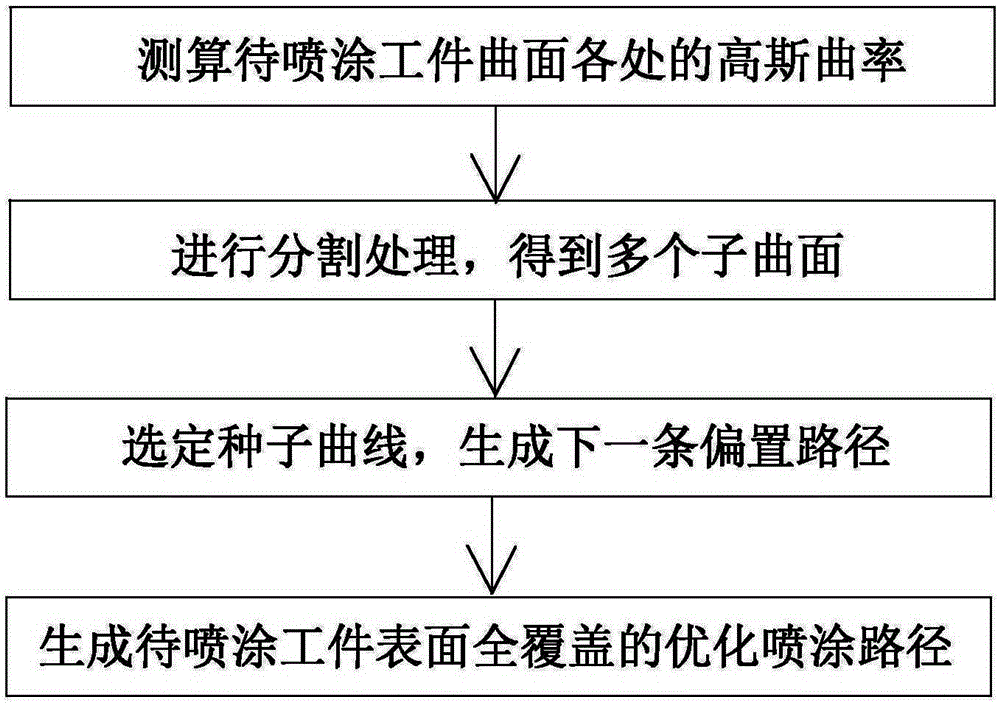

[0086] Such as figure 1 As shown, a method for automatically generating a path for a spraying robot based on surface curvature in an embodiment of the present invention includes the following steps:

[0087] Step 1: According to the STL format model of the workpiece to be sprayed, measure and calculate the Gaussian curvature of the curved surface of the workpiece to be sprayed;

[0088] Step 2: Segment the surface of the workpiece to be sprayed by using the improved watershed algorithm based on Gaussian curvature and the projection approximate segmentation method to obtain multiple sub-surfaces with gentle surface curvature and simple topology;

[0089] Step 3: Use the geodesic method to select the seed curve on a sub-surface, and optimize the current path speed and adjacent stroke distance according to the deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com