Shunt device and casting system for magnesium alloy semi-continuous casting

A shunt device and magnesium alloy technology, which is applied in the field of semi-continuous casting shunt devices, can solve the problems of high probability of hot cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In a specific embodiment of the present invention, the preparation method of the zirconia matrix porous ring 5 preferably includes the following steps:

[0045] Mixing zirconia and a binder, followed by preforming and sintering in sequence to obtain a zirconia matrix porous ring;

[0046] The binders include polystyrene, sodium hyaluronate, and polymethylmethacrylate.

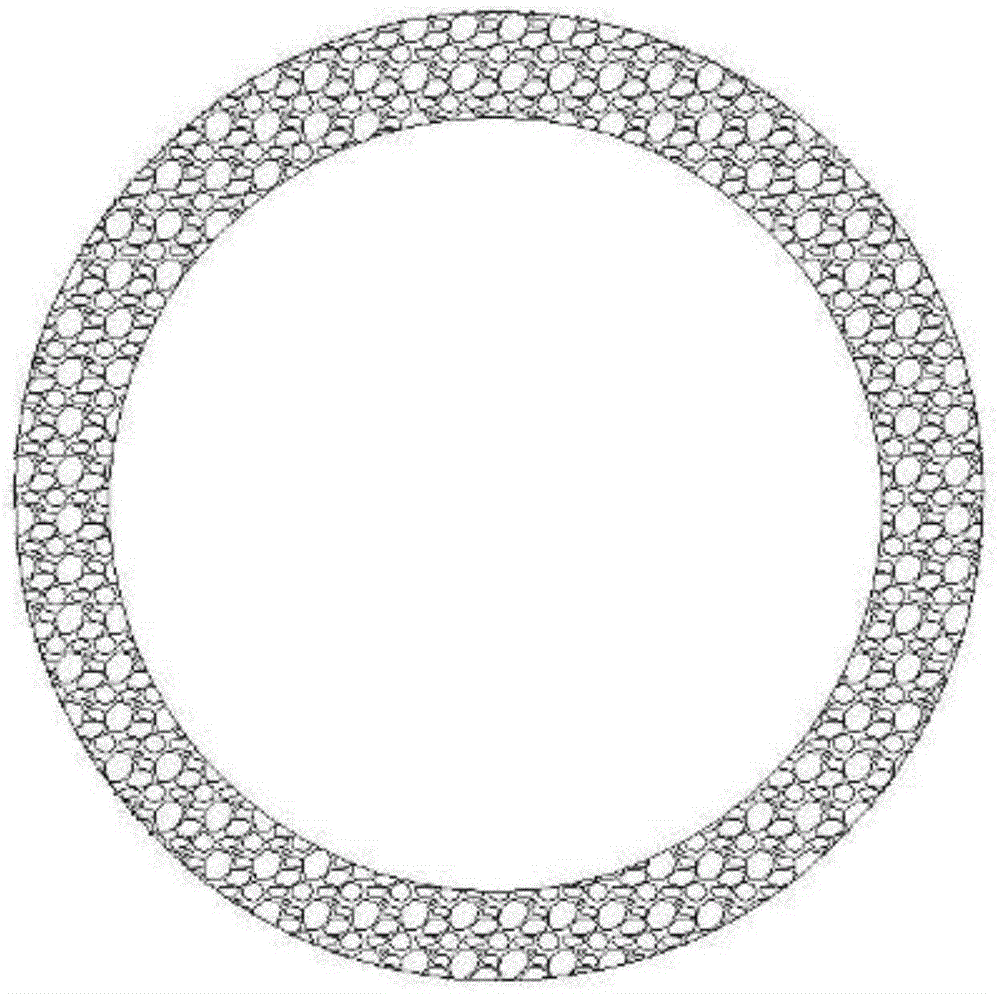

[0047] In the present invention, the particle size of the zirconia is preferably 1.5-6 mm; the present invention has no special limitation on the source of the zirconia, and the above-mentioned zirconia well known to those skilled in the art can be used. sell goods. In the present invention, the particle size of the zirconia has a certain influence on the average diameter of the pores in the porous ring 5 of the zirconia matrix. The larger the particle size of the zirconia, the larger the average diameter of the pores in the formed porous ring.

[0048]In the present invention, the binder includes poly...

Embodiment 1

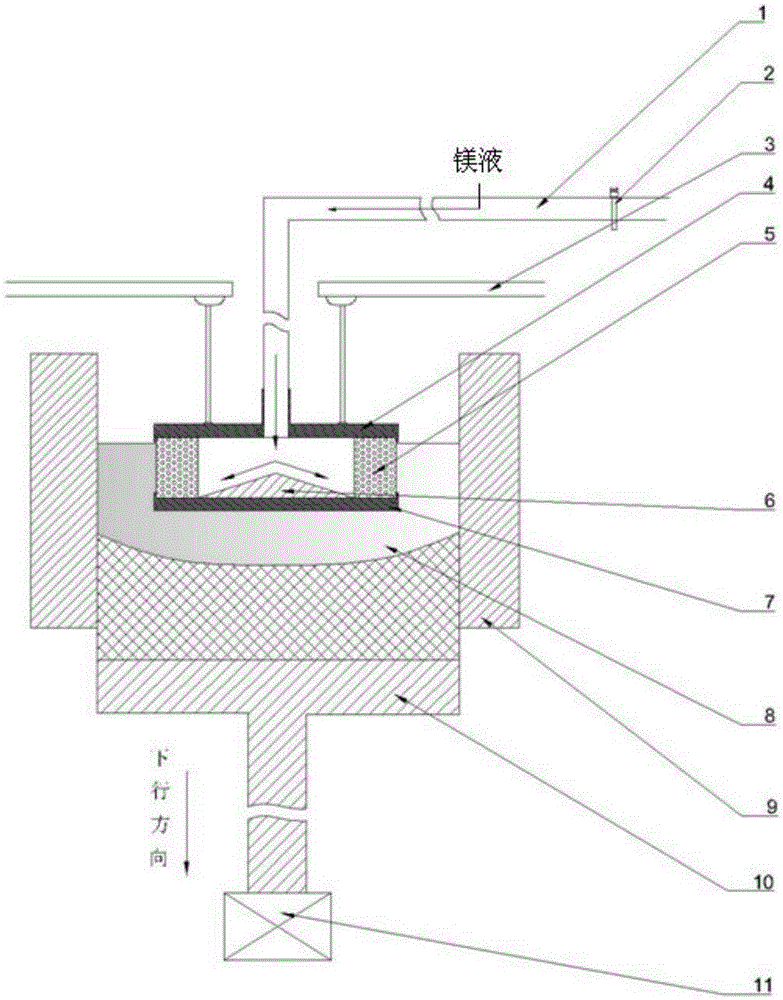

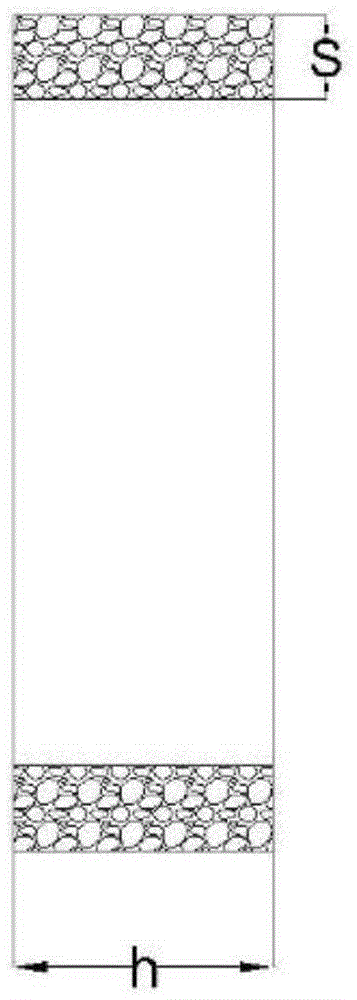

[0073] Prepare a high temperature resistant adhesive according to the composition of the following volume ratio: polystyrene: 30%; sodium hyaluronate: 40%; polymethyl methacrylate: 30%, mix 2mm zirconia ceramic particles with the above adhesive , the volume of zirconia ceramic particles is 50%, stirring in a mixer for 15 minutes, placing the mixed mixture in a mold and cold pressing to form a ring blank, the outer diameter of the ring blank is 120 mm, and the thickness is 35 mm. The height is 60mm, and the dried billet is sintered in a high-temperature furnace. The sintering process is: 300°C for 20 hours; 1550°C for 5 hours, and then vibrate and clean the porous ring. The average hole diameter of the zirconia matrix porous ring is 6mm. , blow dry the porous ring after cleaning, and install the upper and lower cover discs. Place the diverter device in accordance with the figure 1 As shown in the assembly, use a crystallizer with a diameter of 600mm to cast MB26 magnesium allo...

Embodiment 2

[0075]Prepare a high temperature resistant adhesive according to the composition of the following volume ratio: polystyrene: 35%; sodium hyaluronate: 30%; polymethyl methacrylate: 35%, mix 6mm zirconia ceramic particles with the above adhesive , the volume of zirconia ceramic particles is 55%, stirring in a mixer for 15 minutes, placing the mixed mixture in a mold and cold pressing to form a ring blank, the outer diameter of the ring blank is 150 mm, and the thickness is 20 mm. The height is 35mm; the dried ring blank is sintered in a high-temperature furnace. The sintering process is: 300°C for 20 hours; 1550°C for 5 hours, and then vibrate and clean the zirconia matrix porous ring. The average hole diameter is 10mm, the zirconia matrix porous ring is cleaned and dried, and the upper cover and the lower cover disc are installed; the shunt device is installed according to figure 1 Assembled as shown, using a crystallizer with a diameter of 500mm to cast the Mg-10Gd-3Y-0.5Zr ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com