A position correction device

A technology of a correction device and a limit device, which is applied in the direction of feeding devices, automatic control devices, manufacturing tools, etc., can solve problems such as deviations and work errors, improve processing accuracy, have strong versatility and economy, and shorten position adjustment time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

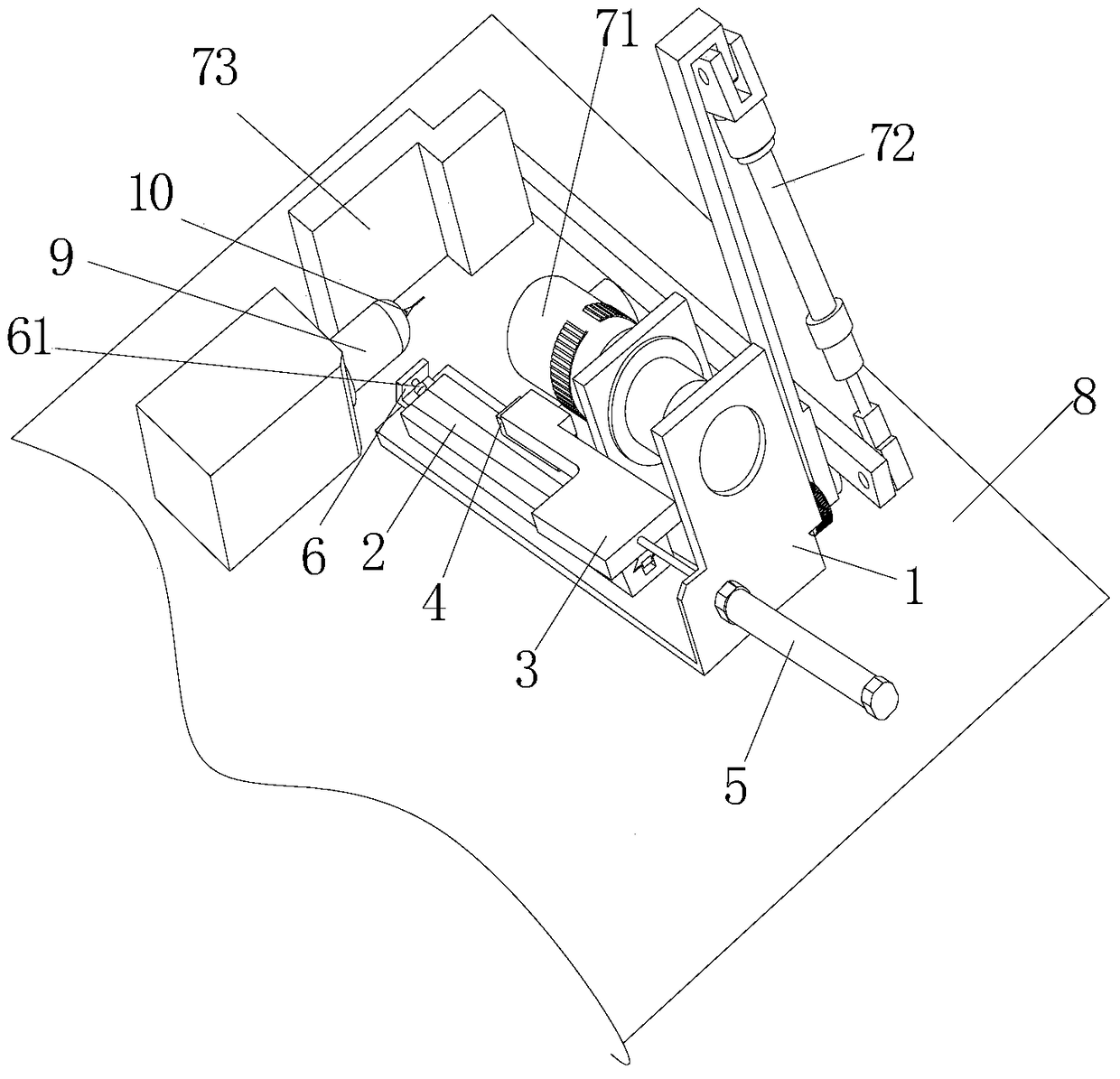

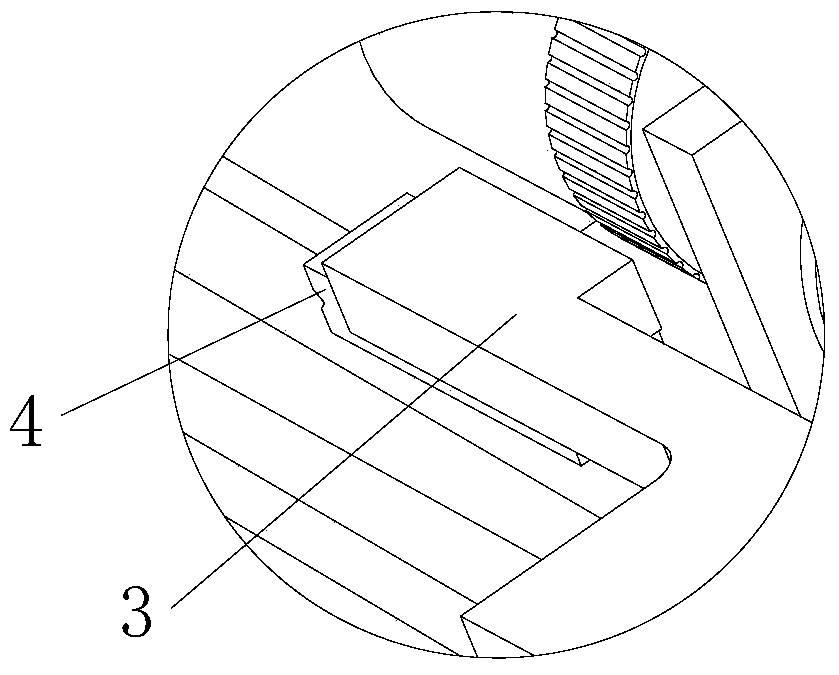

[0020] Such as figure 1 and figure 2 As shown, the position correction device is installed on the machine tool 8, and the position correction device includes a base 1, a guide rail 2 installed on the base 1, a sliding ejector rod 3 installed on the guide rail 2, and a front end of the sliding ejector rod 3 for moving the workpiece 10 Groove head 4 with the top offset from the center of the machining circle, a push rod 5 installed on the base 1 for pushing and pulling the sliding ejector rod 3 to slide along the guide rail 2, a limit device 6 installed at the front end of the guide rail 2, a workpiece angle imaging device and an information processing system .

[0021] Wherein: the guide rail 2 is a dovetail groove guide rail, and the sliding ejector rod 3 is installed on a sliding bearing adapted to the guide rail 2 to slide back and forth; the groove top 4 is a V-shaped block whose opening is parallel to the workpiece; the push rod 5 is adopted in this embodiment The cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com