Rear frame assembly

A technology for rear frame and components, which is applied to bicycle frames, bicycle accessories, motorcycles, etc., can solve problems such as interference, insufficient fixing strength, and limited fuel tank space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical means adopted by the present invention to achieve the intended purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

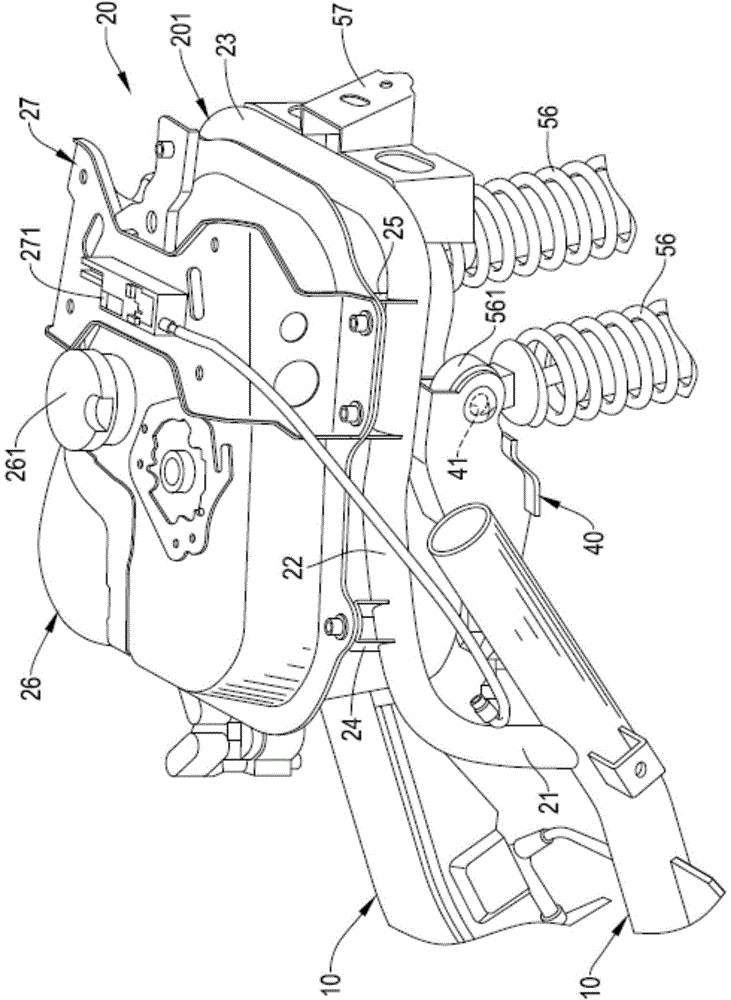

[0027] see Figure 4 , the rear frame assembly of the present invention can be combined on the frame 50 of the motorcycle.

[0028] The vehicle frame 50 includes a head pipe 51 , a main pipe 52 , two side pipes 53 , a connecting section 54 , two pedal sections 55 , two shock absorbers 56 and a rear soil removal (fender) bracket 57 . One end of the main pipe 52 is fixed on the lower end of the head pipe 51 . Two side pipes 53 are respectively fixed on two sides of the other end of the main pipe 52 . Both ends of the connecting section 54 are respectively fixed on the two side pipes 53 . The two pedal sections 55 are respectively fixed on the two side tubes 53 .

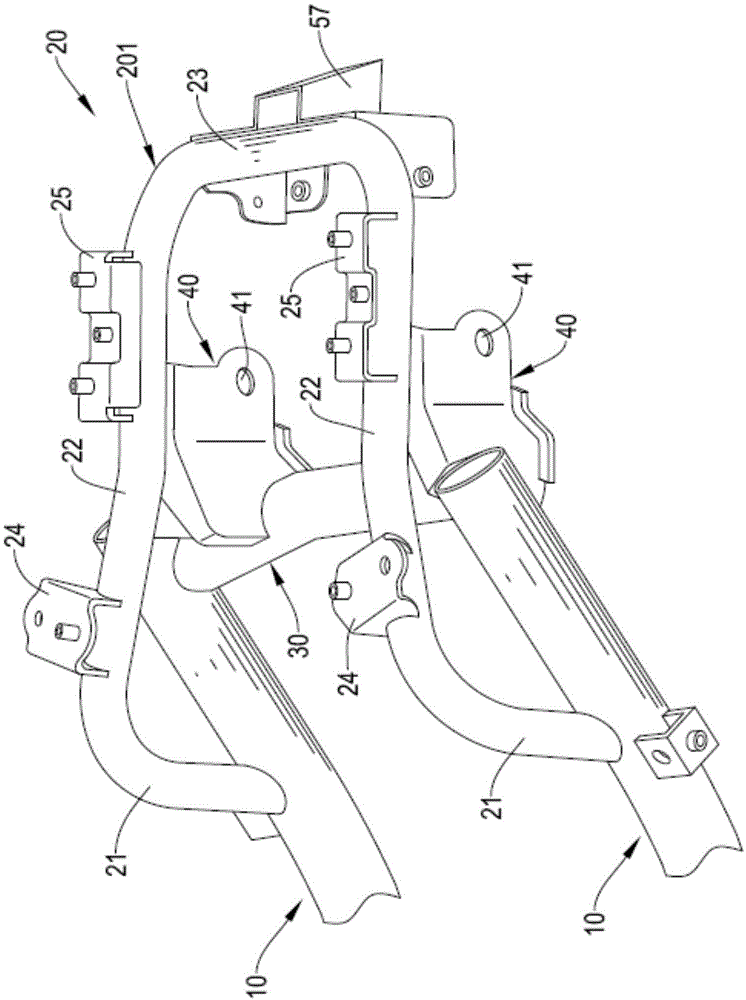

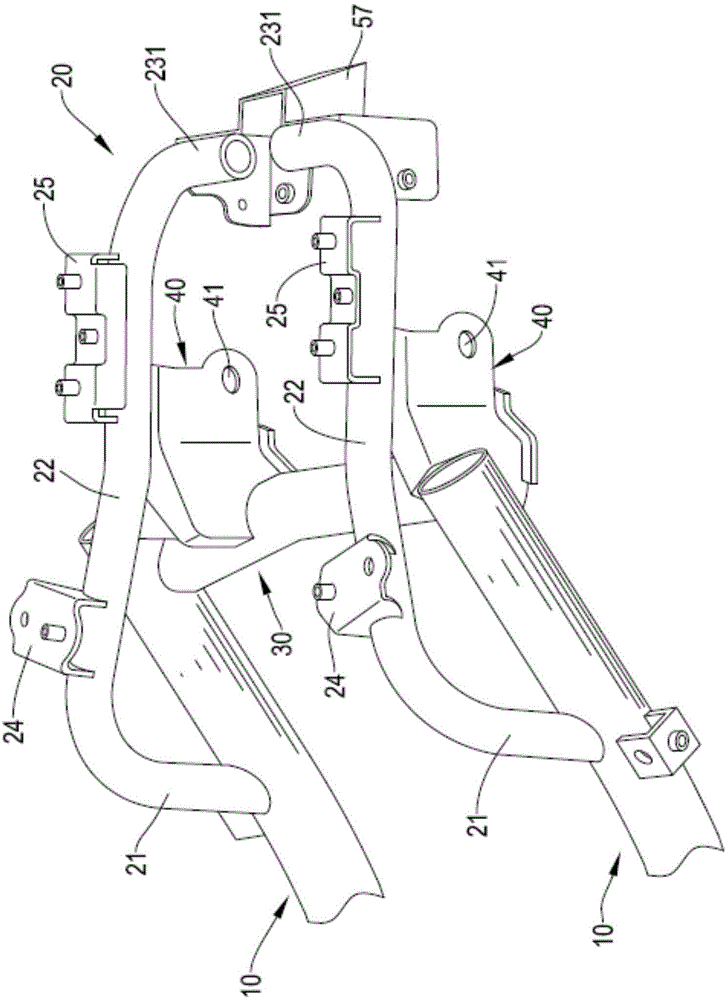

[0029] see figure 1 and image 3 , The first embodiment of the rear frame assembly of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com