Drying method of lost foam, preparation method of lost foam

A technology of lost foam and drying room, which is used in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high labor cost, low lost foam coating, and inability to scour, so as to improve efficiency and reduce processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment discloses a drying method for lost foam, which includes the following steps:

[0044] Step 1. Send the coated foam mold to the coating drying room for pre-drying under the condition of circulating hot air; the temperature of circulating hot air is 30℃~35℃, the wind speed is 1.5M / S~2.5M / S The wind pressure is 0.1Pa~0.6Pa, the humidity of the drying room is 30%~35%, and the drying time is 2h~3h;

[0045] Step 2. Send the pre-dried foam mold in step 1 to the drying room in front of the furnace, and dry it under the condition of circulating hot air; the temperature of circulating hot air is 30℃~50℃, and the wind speed is 0.5M / S~1.5M / S , Wind pressure 0.1Pa ~ 0.6Pa, drying room humidity 15% ~ 20%, drying time 6h ~ 8h.

[0046] The present invention distinguishes the ovens with different uses and uses them separately for their uses. First, the drying room is divided into a coating drying room and a furnace drying room. The coating and hanging drying room do...

Embodiment 2

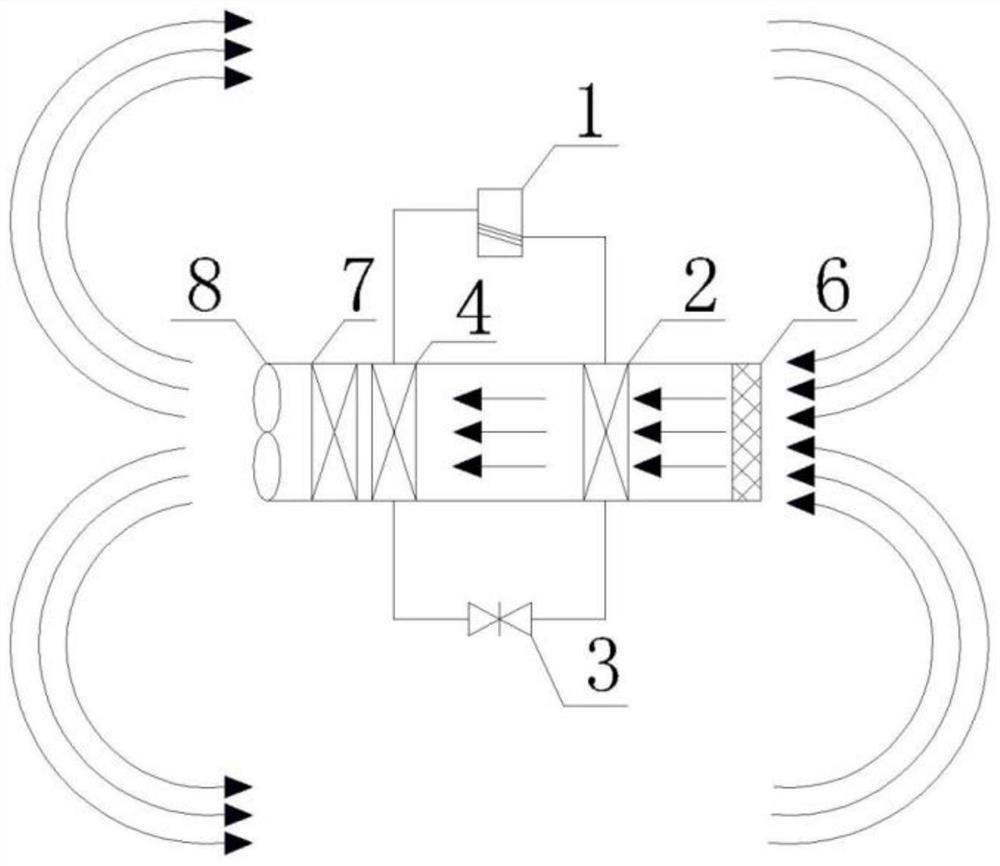

[0050] This embodiment discloses a heat circulation air dehumidification and heating circulation system in a drying room, which is used in a coating drying room and a furnace front drying room. The coating and hanging drying room and the furnace front drying room of the present invention are respectively equipped with a thermal circulation air dehumidification heating circulation system in the drying room. This example introduces the thermal circulation air dehumidification heating circulation system in the drying room in front of the furnace as the object. The thermal circulation wind dehumidification heating circulation system in the drying room of the coating and hanging drying room refers to the thermal circulation wind dehumidification heating in the drying room of the furnace front drying room. circulatory system.

[0051] Including compressor 1, evaporator 2, expansion valve 3, condenser 4, filter screen 6, radiator 7, induced draft fan 8, compressor 1, condenser 4, exp...

Embodiment 3

[0054] This embodiment discloses a method for preparing a lost foam, comprising the following steps:

[0055] Step 1, preparation of lost foam coating;

[0056] Step 2: bonding and combining multiple pieces of foam mold parts into a single casting, and reserving a first bonding surface glued to the ingate in the casting monomer, and pasting the first bonding surface on the first bonding surface first tape;

[0057] Step 3: bonding the sprue, runner, and ingate to form a sprue assembly, and reserving a second bonding surface glued to the casting monomer on the surface of the ingate, and A second adhesive tape is pasted on the second bonding surface;

[0058] Step 4. Submerge the casting monomer with the first tape pasted in step 2 and the runner assembly with the second tape pasted in step 3 into the lost foam coating for 2 minutes;

[0059] Step 5. Take out the casting monomer and sprue assembly after coating and hanging in step 4, and pour off the excess paint;

[0060] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com