Lifting driving method and device

A lift drive and drive arm technology, applied in textiles and papermaking, etc., can solve the problems of complex mechanism, large space occupation, and poor consistency of movements of the left and right side devices, so as to reduce costs, save space, and ensure consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0020] The present invention solves the shortcomings of the prior art and provides an air frame lifting drive device and method. The device and method enable only one set of ball screw pair used in the trolley collection device of the spinning frame and is installed in the car belly The middle position saves mechanical space, while the structure is simple and compact, which is convenient for maintenance and operation.

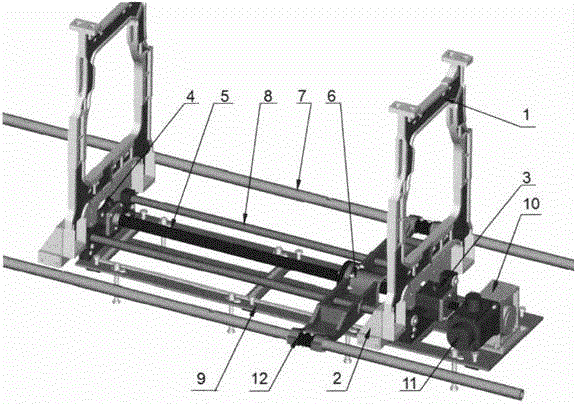

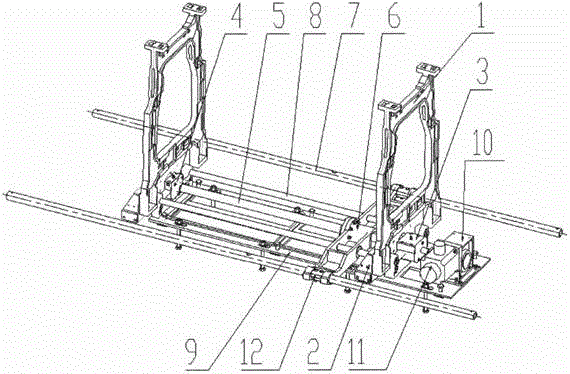

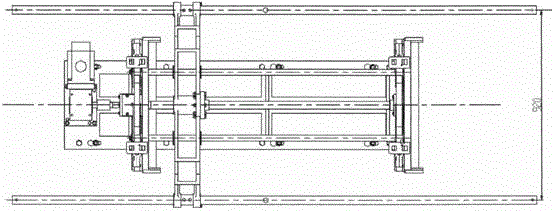

[0021] figure 1 This is a three-dimensional schematic diagram of a lifting driving method and device provided by embodiments of the present invention. Such as figure 1 As shown, a lifting driving method and device are applied to a short spinning frame. The device includes: a wall plate 1, a transmission tube base 2, a first bearing seat 3, a second bearing seat 4, and a ball screw pair 5. Transmission pipe connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com