Lower plate surface of plastic steel window sash sectional material

A technology of fan profiles and plastic-steel windows, which is applied to the layout of wing leaves, windows/doors, and wing leaf frames. strength, the effect of simplifying the installation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

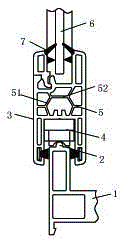

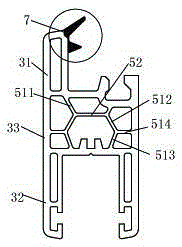

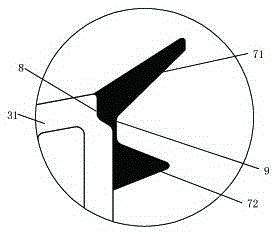

[0016] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0017] like Figure 1 to Figure 4 As shown, the plastic-steel sash installation mechanism of the sliding window, the plastic-steel sash installation mechanism of the sliding window includes a base 1, the upper part of the base 1 is a slide bar 2, and the slide bar 2 of the base 1 passes through a sliding connector 4 It is connected with a plastic-steel window sash profile 3 that can slide on the slide bar 2. The plastic-steel window sash profile 3 includes an upper panel surface 31, a lower panel surface 32 and a side panel surface 33. Both ends of the upper panel surface 31 and the lower panel surface 32 pass through The side panels 33 are connected as a whole, and honeycomb reinforcing ribs 5 are arranged between the upper panel 31, the lower panel 32 and the side panels 33, and the lower panel 32 is connected with the slide bar 2, and the The top of the upper panel 31 is connected with a window ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap