Preignition control method for supercharge non-direct-injection gasoline engine

A technology of gasoline engine and control method, applied in engine control, combustion engine, fuel injection control and other directions, can solve the problem that PFI engine does not have, and achieve the effect of reducing the probability of super knocking, improving reliability and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

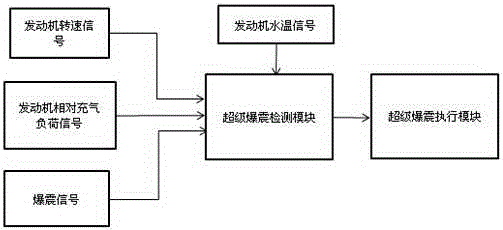

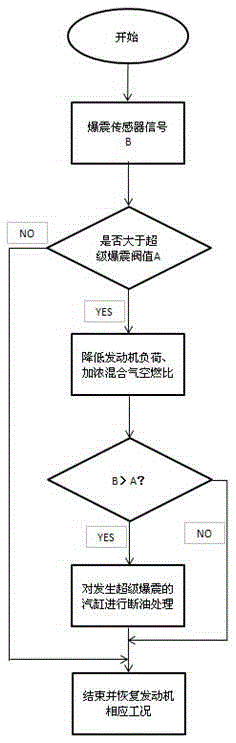

[0016] see figure 1 , the general control method that the present invention solves super-knock is: when the engine stand is demarcated and matched, the threshold A when super-knock takes place is calibrated according to the engine cylinder pressure and the knocking sound intensity. The super knock detection module judges whether super knock occurs according to the signal B measured by the knock sensor. When B>A, the controller determines that there is a super knock occurring at this time. At this time, the system will reduce the charge load of the engine and enrich the air-fuel ratio of the mixture. This measure lasts for a period of time (scaleable). When the system detects that there is no super knock, the controller will restore the proper operating conditions of the engine within a certain period of time (can be calibrated).

[0017] Specific control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com