Photoelectric polymerization refrigerating and heating system and method

A cooling, heating and photoelectric technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of complex structure, high safety hazard, and incompatibility of independent system settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

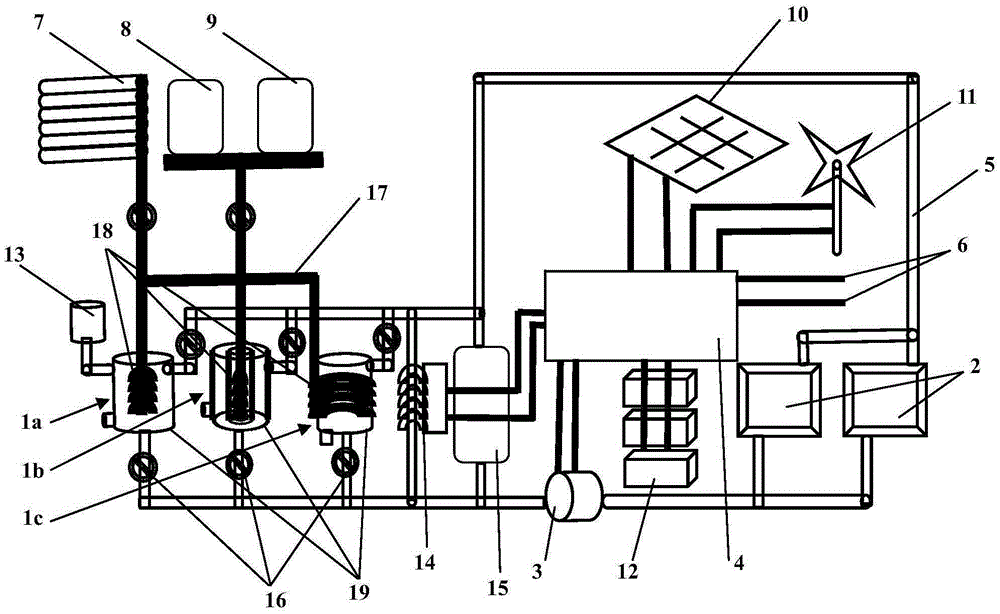

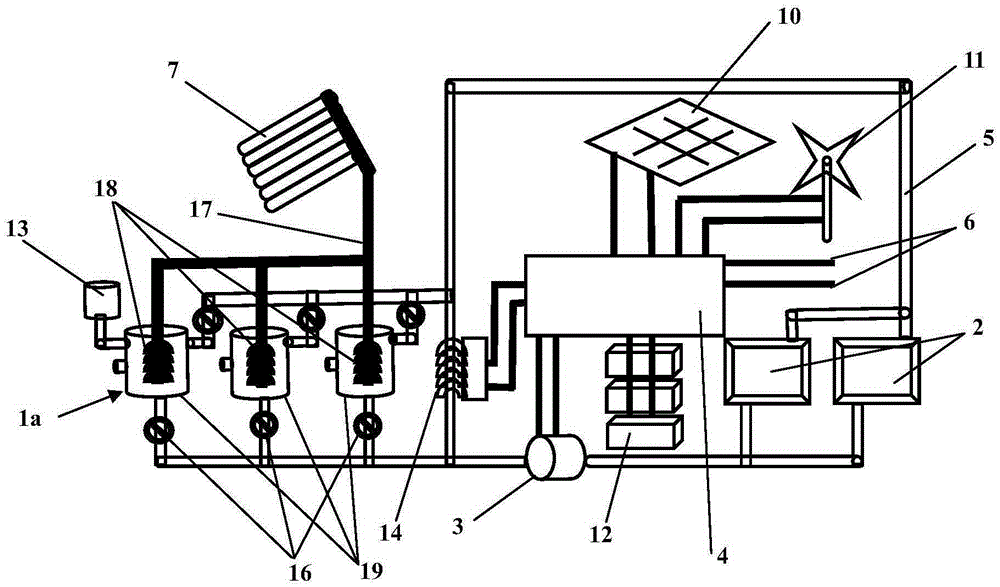

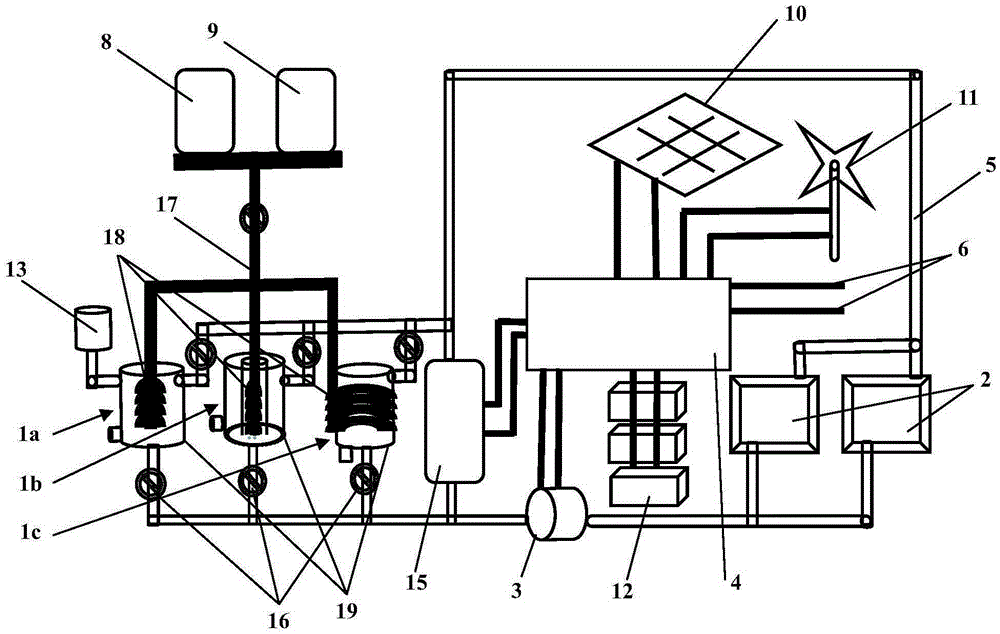

[0043] The present invention will be described below in conjunction with the accompanying drawings.

[0044]The invention discloses a photoelectric polymerization cooling and heating system, which includes at least one of a heating device and a refrigeration device, and also includes a working medium container, a superconducting element, an energy dissipation device, a pipeline and a controller, and the pipeline connects the working medium container It is connected with the energy dissipating device to form a circulation pipeline. One working medium container is arranged in the pipeline or more than two are arranged in parallel. One end of the superconducting element is connected to the heating device and / or refrigeration device. When there is one working medium container, the The other end of the superconducting element extends into the inside of the working medium container or is attached to the outer wall of the working medium container. When there are more than two working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com