Vacuum lignite drying device and using method thereof

A technology of drying device and vacuum dryer, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of complex system, high risk, and large discharge volume, and achieve reasonable equipment structure and high efficiency. Safety, effect of large heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

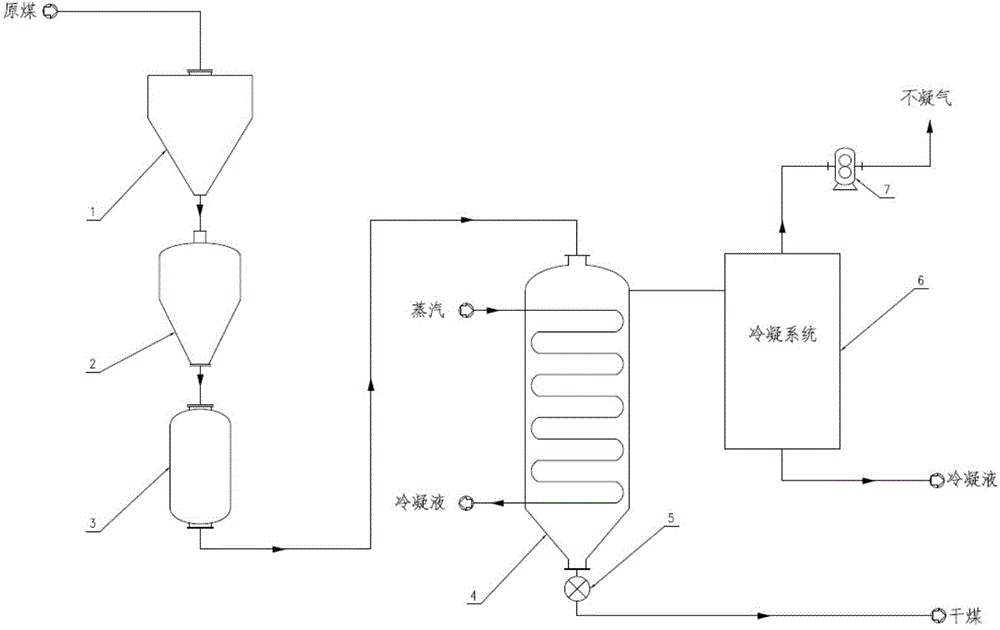

[0023] A vacuum lignite drying device, including a raw coal bunker 1, characterized in that it also includes a vacuum lock hopper 2 connected in sequence, a vacuum feeding tank 3, a vacuum dryer 4 and a condensation system 6, and above the condensation system 6 is a Vacuum pump7.

Embodiment 2

[0025] A vacuum lignite drying device, similar to Example 1, the difference is that a dry coal outlet is provided below the vacuum dryer 4 through a discharge valve 5; The vacuum feed tank 3 is set under the vacuum lock hopper 2 through a valve; the top of the raw coal bunker 1 is provided with a raw coal inlet; the upper part of the vacuum dryer 4 is provided with a steam inlet, and the lower part is provided with a condensation liquid outlet; the top of the condensation system 6 is provided with a non-condensable gas outlet connected to the vacuum pump 7, and the bottom is provided with a condensate outlet.

Embodiment 3

[0027] A method of using a vacuum lignite drying device. First, the lignite is stored in the raw coal bunker 1 and sent to the vacuum lock hopper 2 through a valve. At this time, the valve at the bottom of the vacuum lock hopper 2 is in a closed state, and its upper part is communicated with the raw coal bunker 1. , in a state of normal pressure; after the discharge is completed, the valve on the top of the vacuum lock hopper 2 is closed, and a vacuum environment is established. After the vacuum degree reaches the set value, the discharge valve 5 at the lower part of it is opened, and the material is discharged to the vacuum feed tank 3; At this time, the vacuum feeding tank 3 continues to send the raw material lignite into the vacuum drier 4, and the lignite exchanges heat with the atmospheric pressure steam that is passed into the heat exchange tube inside the vacuum drier 4, because the inside of the vacuum drier 4 is in a negative pressure environment, the boiling point of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com