Simulation test device of pressure-bearing underwater coal mining and application method of simulation test device

A technology of simulation test and simulation device, applied in the fields of mining machinery and education, which can solve the problems of unclear vision, great influence, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

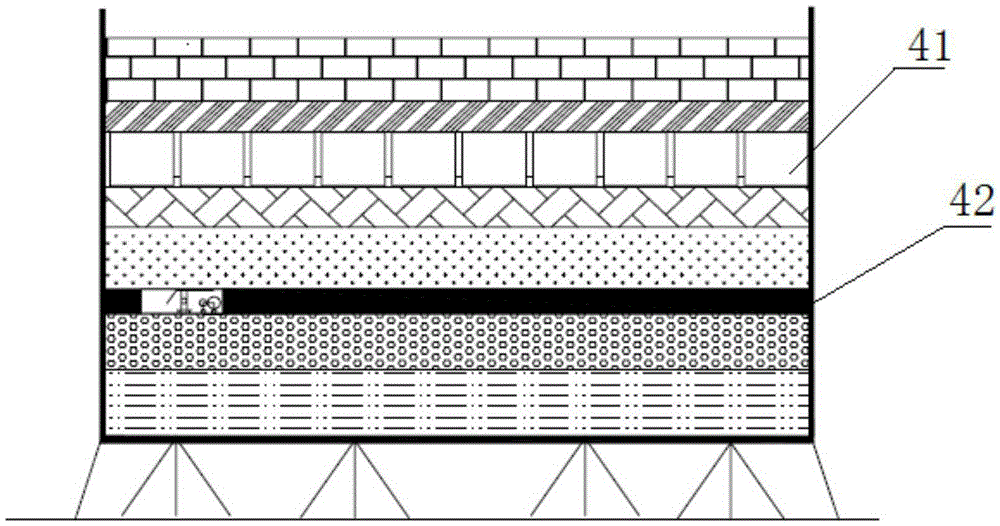

[0074] Such as figure 1 As shown, the simulated test device for mining coal under pressure in the present invention includes a frame body, a pressure-bearing aquifer 41 arranged on the frame body, a coal seam 42, support rods arranged on both sides of the coal seam 42, and other rock formations;

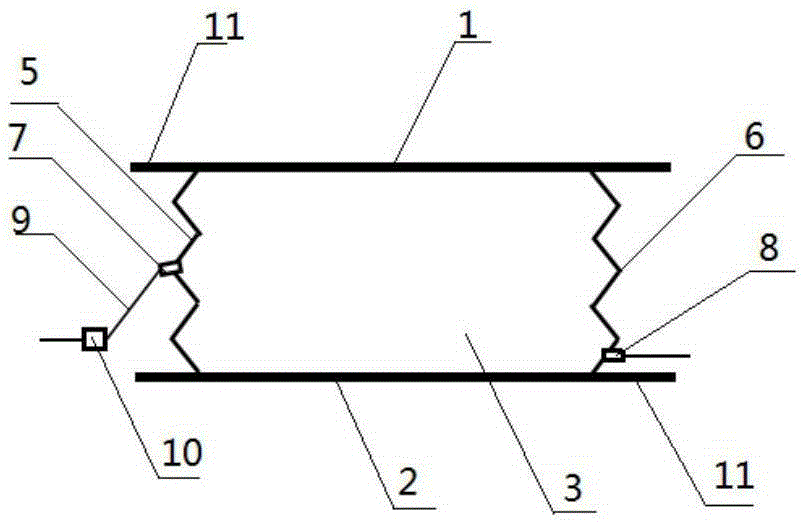

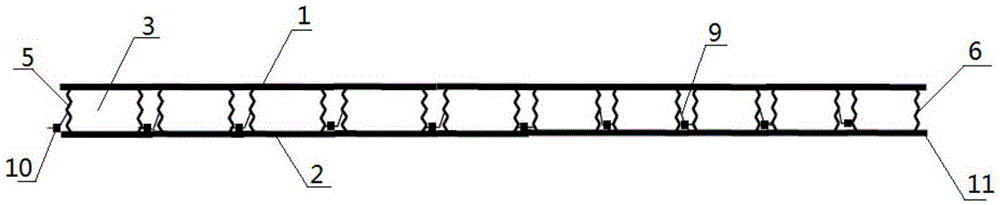

[0075] Such as Figure 2 to Figure 6 As shown, the confined aquifer is formed by connecting multiple small water bags, and the small water bag is composed of the top plate 1 of the water bag, the bottom plate 2 of the water bag, the front side wall 3, the rear side wall 4, the left side wall 5 and the right side wall 6 enclosed cuboid structure, its inside is a water-filled space, a water inlet 7 is arranged on the left side wall of the small water bag, a water outlet 8 is arranged on the right side wall, and the water inlet 7 of the last small water bag Connect to the water outlet 8 of the previous small water bag through the water delivery pipe 9, the water inlet 7 of the first sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com