Ultra-high voltage power transmission line equipotential live working device and use method thereof

A technology for transmission lines and live work, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of demanding safety distance, unfavorable organization and implementation, and affecting operation time and efficiency, so as to achieve low manufacturing cost, save manpower, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

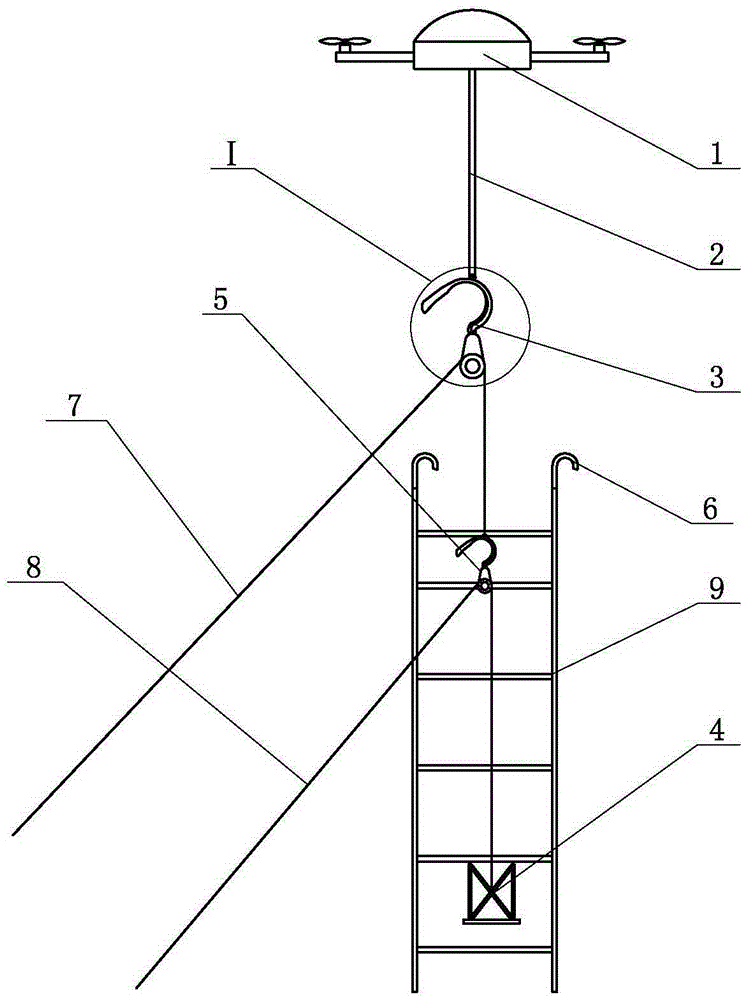

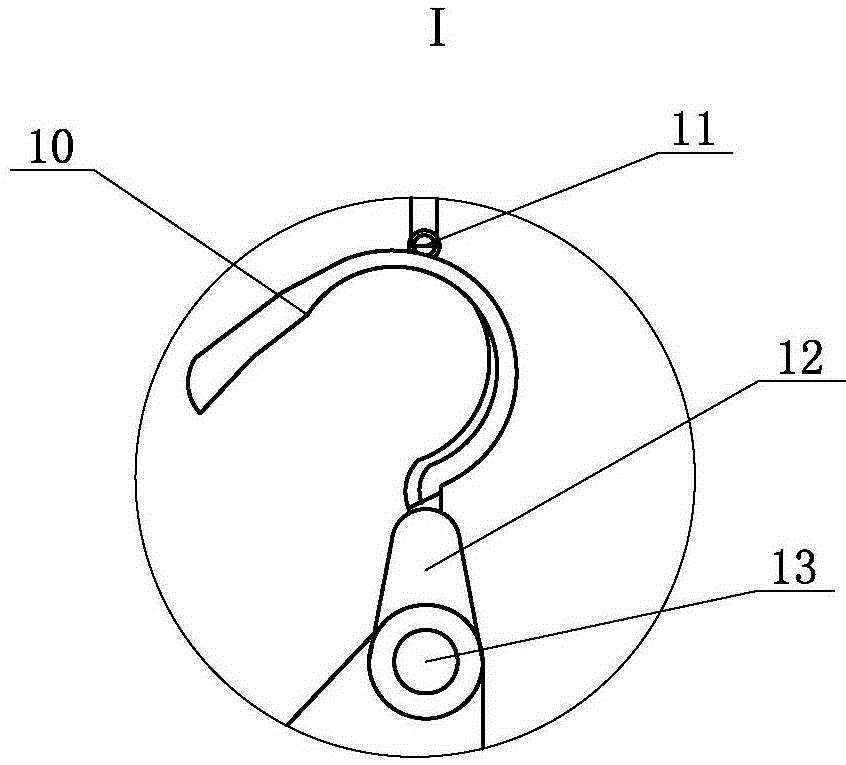

[0012] An equipotential live working device for ultra-high voltage transmission lines, such as figure 1 and figure 2 As shown, the UAV 1 and two insulating tackles are included. The insulating tackles are respectively an upper insulating tackle 3 and a lower insulating tackle 5. The insulating tackle is composed of a shell 12, a hook body 10, a pulley 13 and a hanging ring 11. Pulley 13, an inverted hook body 10 is arranged on the upper part of the housing 12, and a hanging ring 11 is installed on the upper part of the hook body 10; the UAV 1 is connected to the upper end of the insulating lanyard 2, and the lower end of the insulating lanyard 2 is connected to the hanging ring of the insulating tackle 3 11. The pulley 13 of the upper insulating block 3 is wound with a ladder stay rope 7, and the end of the ladder stay rope 7 is connected to the top of the ladder 9; the top of the ladder 9 is provided with a ladder hook 6. In order to improve safety, the end of the ladder st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com