Automatic electric pole climbing mechanism

A technology for automatic climbing and electric poles, which is applied in the direction of climbing and sports accessories, can solve the problems of increasing the risk factor of the staff's operation, reduce the scope of power outages, reduce the steps of pedaling and close-range electric inspection operations, and increase benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

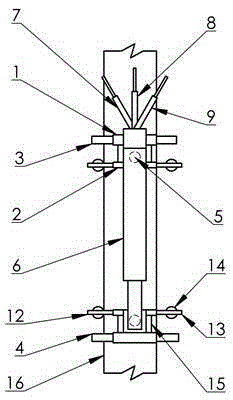

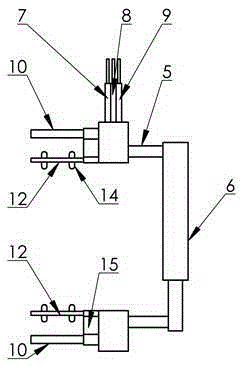

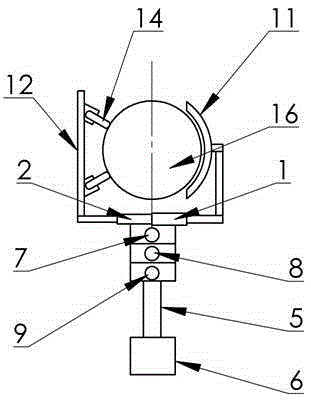

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0024] A pole automatic climbing mechanism, such as Figure 1 ~ Figure 3 As shown, it includes an upper hoop 3, a lower hoop 4, an auxiliary rolling body, a telescopic oil cylinder 6, a workbench, a connecting column cylinder 5, and a hydraulic station (not shown in the figure).

[0025] The upper hoop 3 and the lower hoop 4 are set opposite to each other up and down, and have the same structure, including a left half hoop 10 and a right half hoop 11 enclosing the pole 16 . The left half hoop 10 and the right half hoop 11 are 1 / 4 arc ring structures that enclose the electric pole, and the inner arc surfaces of the left half hoop 10 and the right half hoop 11 are conical surfaces that are small at the top and large at the bottom. The taper of the pole 16 is matched, and anti-slip lines are set on the conical surface. The connecting end of the left half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com