A low-cost high-life continuous casting tundish turbulence controller and its preparation method

A technology of turbulent flow controller and continuous casting tundish, which can be applied to casting equipment, casting melt container, manufacturing tools, etc., and can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

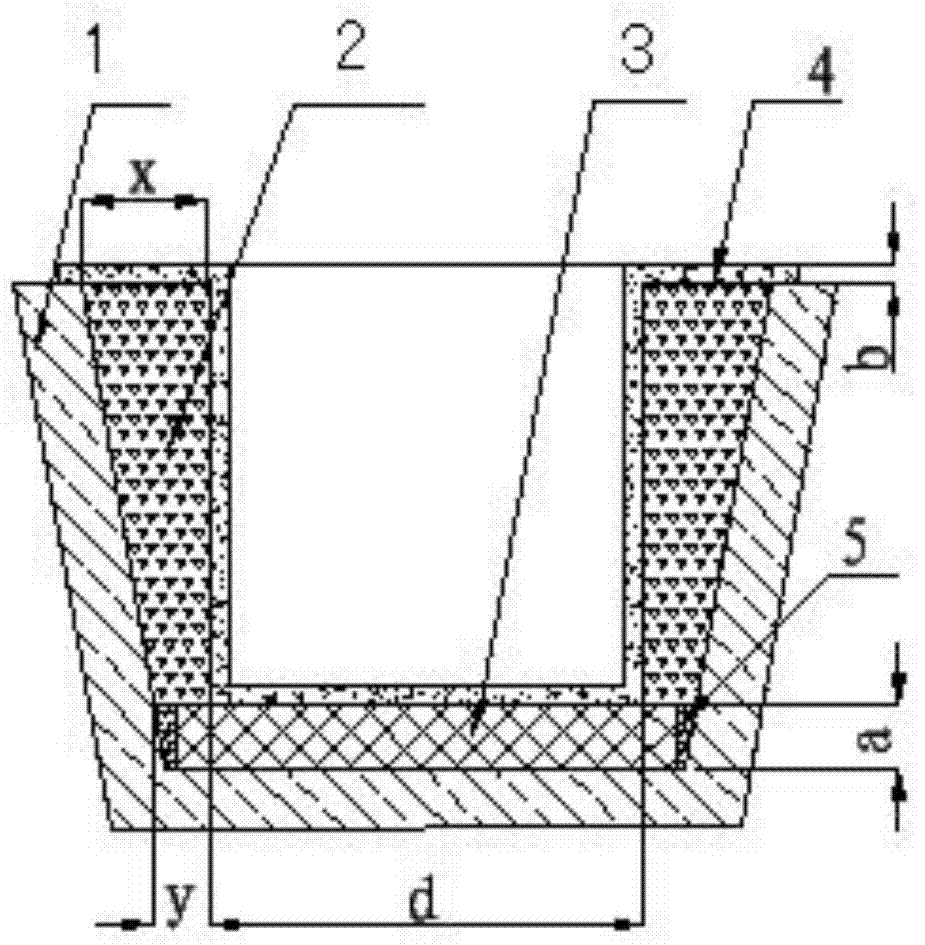

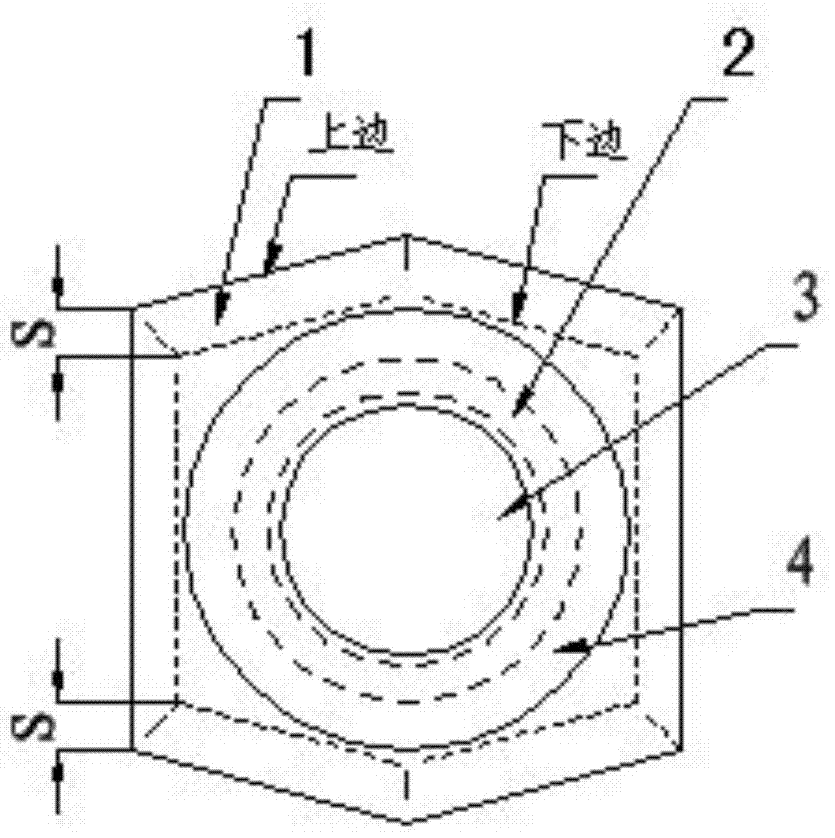

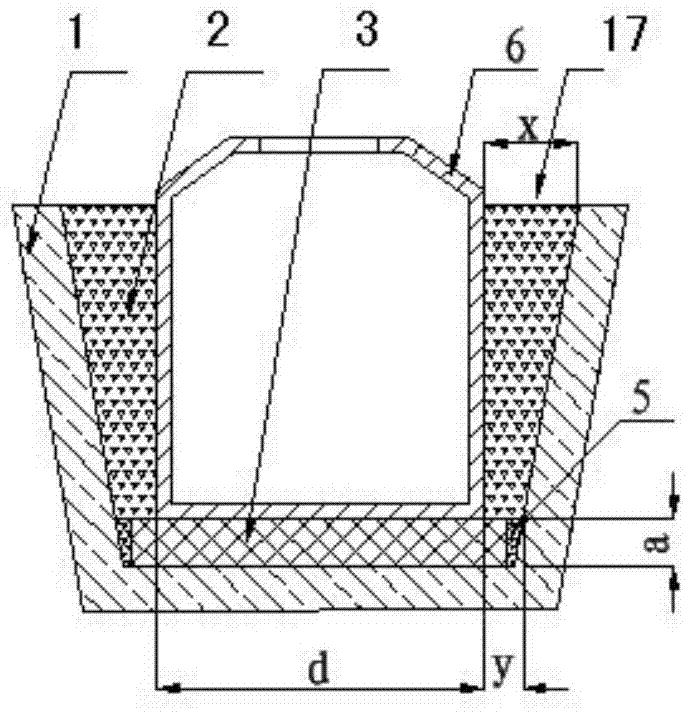

[0009] A low-cost and high-life continuous casting tundish turbulence controller, comprising a shell (1), an inner core (2), a bottom plate (3), and a coating material layer (4), and the bottom plate (3) is positioned in the inner cavity of the shell (1) Above the bottom, the bottom of the inner core (2) is positioned on the bottom plate (3), the longitudinal centerline of the inner core (2) coincides with the longitudinal centerline of the inner cavity of the shell (1), and the coating material layer (4) is located in the inner On the outer surface of the core (2) and the bottom plate (3), the shell (1) of the turbulence controller is casted with magnesium castable, the inner core (2) is formed by vibrating recycled dry material, and the bottom plate (3) is made of waste magnesium For carbon brick masonry, the periphery of the bottom plate (5) is filled and compacted with recycled dry-type materials, and the smear layer (4) is made of recycled smear materials.

[0010] Prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com