Grinding process of inner hole of optical interface metal component

A grinding process and optical interface technology, which is applied in the field of inner hole processing of optical interface metal components, can solve the problems of high tolerance cost, disconnection reliability, failure, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

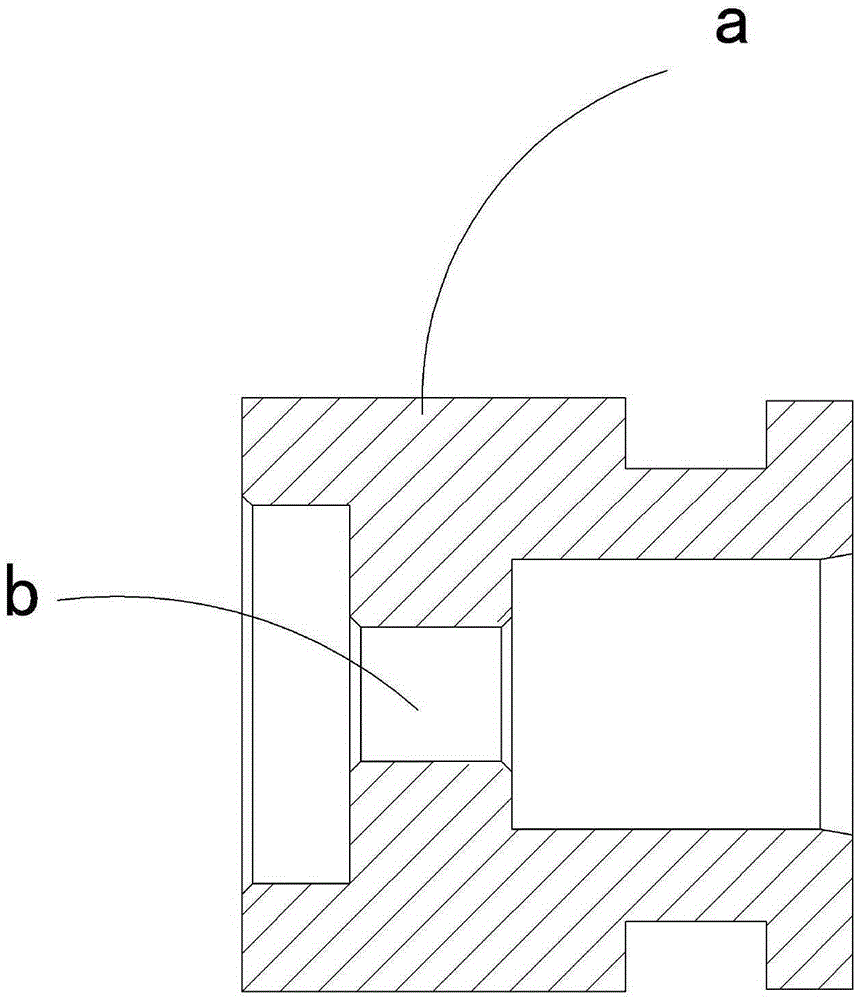

[0017] Example: such as figure 1 Shown is the workpiece that needs to be processed in the embodiment of the present invention. The workpiece a is a component of an optical interface assembly. During installation, a ceramic ferrule needs to be installed in the inner hole of the workpiece a, such as figure 1 The mounting hole b shown is a hole that needs to be matched with the ceramic ferrule. This invention is an embodiment of the grinding process of the inner hole of the metal component of the optical interface. The specific production steps of the grinding process are:

[0018] (1) Use a drill to perform rough machining on a CNC lathe to process the ferrule assembly holes;

[0019] (2), select the steel wire equivalent to this aperture;

[0020] (3), coated with abrasive paste on the steel wire;

[0021] (4), the steel wire is installed on the motor to rotate;

[0022] (5) Wear the product on the steel wire for inner hole grinding;

[0023] (6) Clean the product.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com