One-way edging device for transverse stone slab veneer

A slate and horizontal technology, which is applied in the field of one-way edging device for horizontal slate veneers, can solve problems such as accidental injuries of people, and achieve ideal grinding effect, stable operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

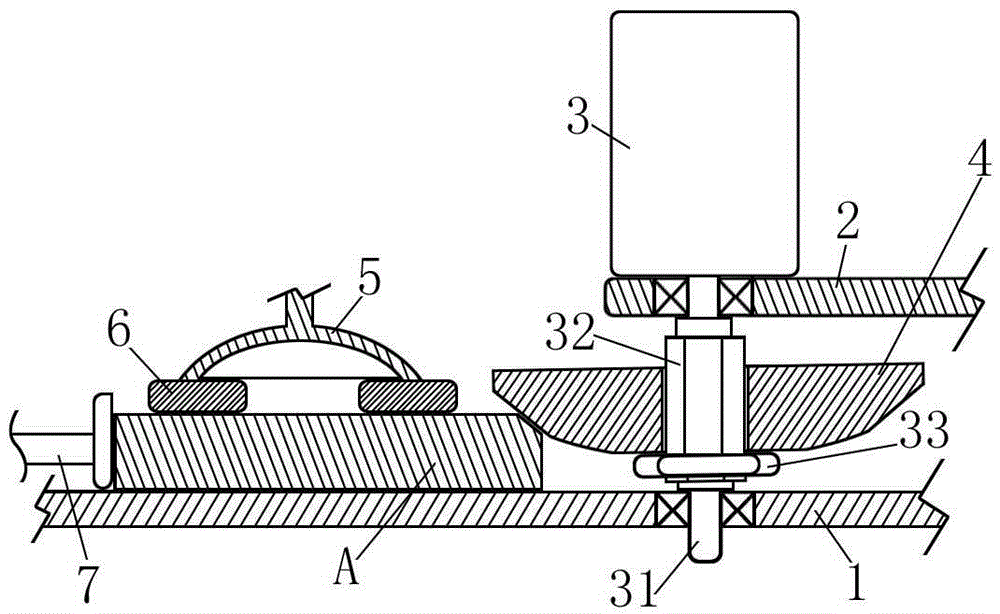

[0011] Such as figure 1 As shown, a horizontal slate veneer one-way edging device is composed of a horizontal material bearing plate 1, a base plate 2, a motor 3, a conical grinding wheel 4, a lower pressing plate 5, a plurality of elastic pressing plates 6, a top Push plate 7 is made up of, it is characterized in that,

[0012] The slate A is placed flat on the top surface of the transverse material receiving plate 1, and a base plate 2 is arranged parallel to the upper right side of the transverse material receiving plate 1. The motor 3 is fastened on the base plate 2, and the shaft of the motor 3 The end is facing down and is firmly connected with the top of the rotating shaft 31. The upper and lower ends of the rotating shaft 31 are respectively connected in series with the base plate 2 and the transverse material receiving plate 1 through bearings. The middle part 32 of the rotating shaft 31 has a prism-shaped structure. The middle part of 4 is provided with a prism-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com