A large-size variable-diameter robotic fixture for processing pipe pile end plates

A robot fixture, large-scale technology, applied in the direction of manufacturing tools, cleaning methods and utensils, chucks, etc., can solve the problems of frequent fixture replacement and low automation, meet the needs of reliable clamping, improve the degree of work automation, stable and reliable clamping lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

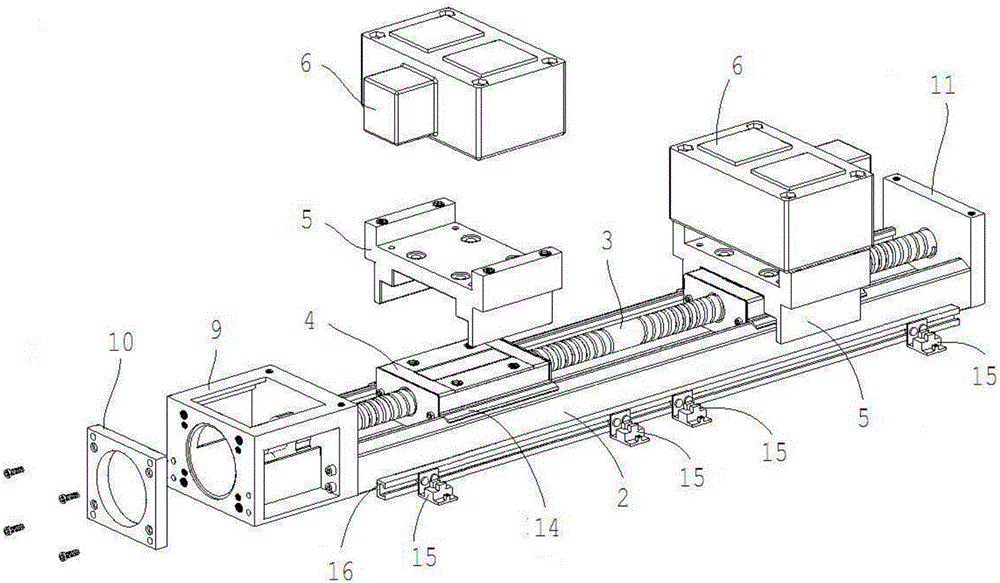

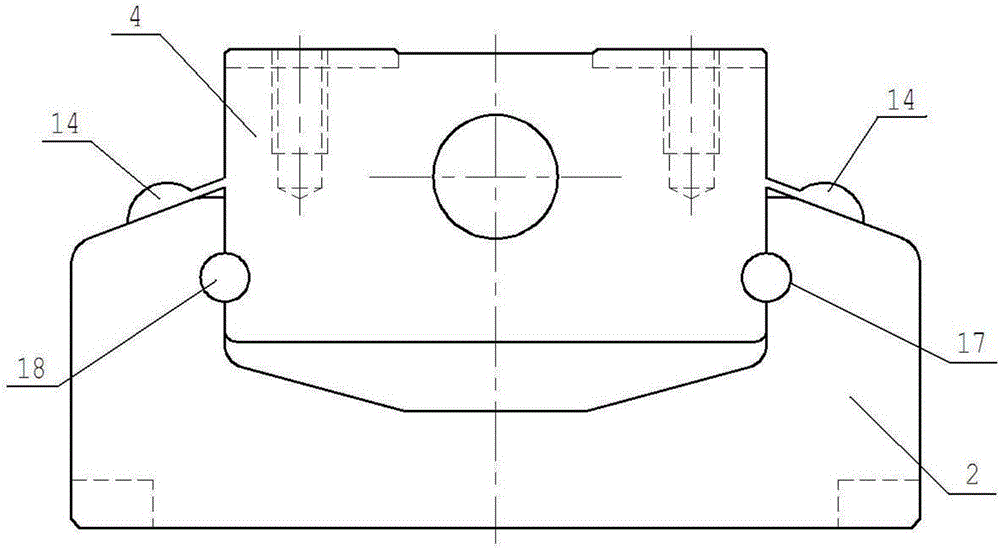

[0022] The present invention will be further elaborated below in combination with specific embodiments and accompanying drawings.

[0023] The clamping mechanism provided by the present invention is a large-size variable-diameter robotic clamping device for processing pipe pile end plates. The mechanism has a simple structure and can meet the needs of fast and reliable clamping of pipe pile end plates of various sizes and specifications. Referring now to the drawings, embodiments of the provided clamp mechanism will next be described.

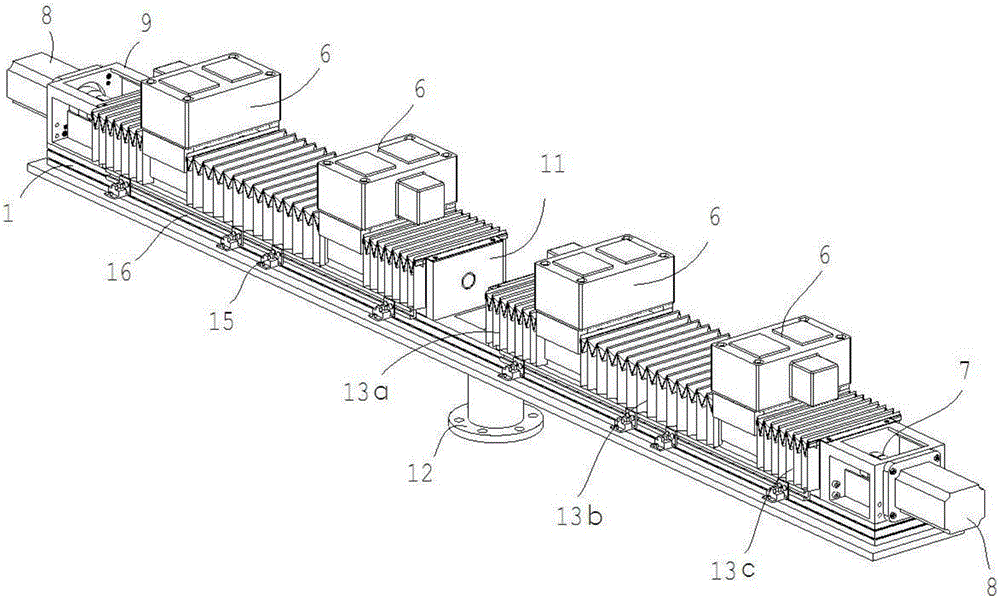

[0024] like figure 1 and figure 2 As shown, a large-size variable-diameter robot clamp for pipe pile end plate processing mainly includes a base, a linear displacement mechanism, a clamping mechanism, a positioning mechanism, and a dust-proof mechanism.

[0025] The base mainly includes a support frame 1 and a robot connecting flange 12. The cross section of the support frame 1 is a rectangular structure, and the four corners are fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com