Pocket underlayer and sewing method thereof

A pocket and cloth pad technology, which is applied to sewing equipment, sewing machine components, textiles, and papermaking, etc., can solve the problems of complex production process of pocket pads, unattractive overall appearance, complex structure of pocket pads, etc., so as to achieve a beautiful overall appearance and improve Garment-making efficiency and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

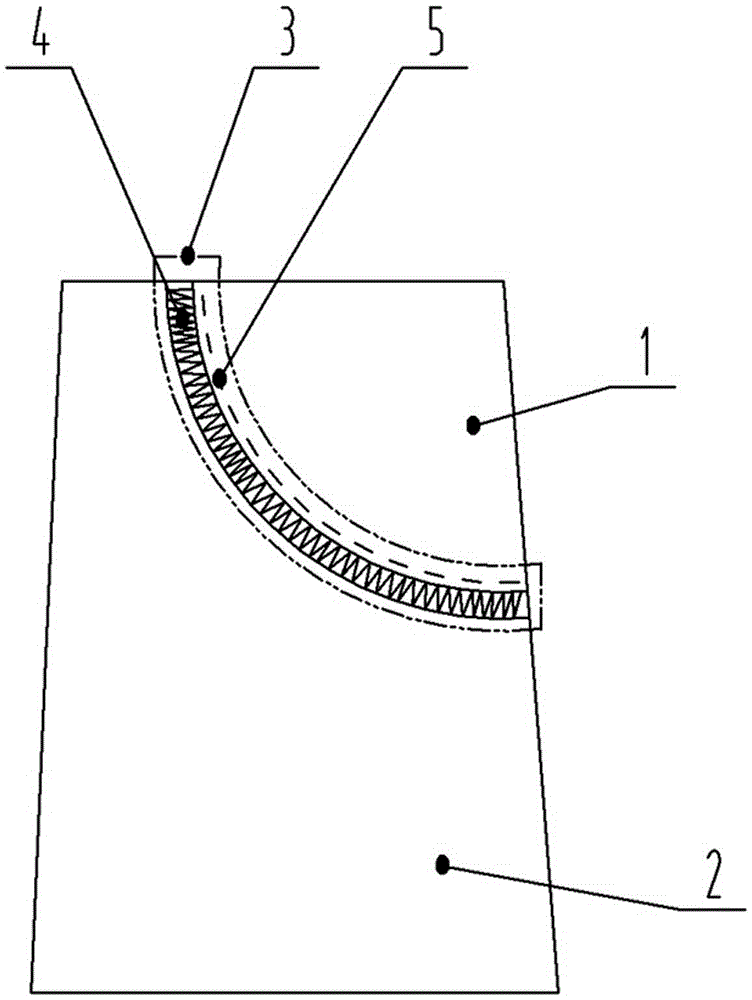

[0022] Embodiment 1: a kind of sewing method of the bottom of the pocket pad, comprising the following steps:

[0023] (1) Select the fabrics of the small doily and the large lining respectively;

[0024] (2) Cut the small doily and lining cloth selected in step (1) according to the required size;

[0025] (3) Ironing the splicing parts of the small doily and the large lining cut and formed in step (2) respectively;

[0026] (4) Splice the small doily and the large lining after ironing in step (3), and sew them with an interlock sewing machine.

Embodiment 2

[0027] Example 2: A sewing method for the bottom of a pocket, the difference from Example 1 is that in step (2), the small doily is cut into a fan shape according to the required size, and the large lining is cut according to the required size It is an isosceles trapezoid, and a scalloped notch matching the size of the doily is cut at one corner of the top side of the isosceles trapezoid.

Embodiment 3

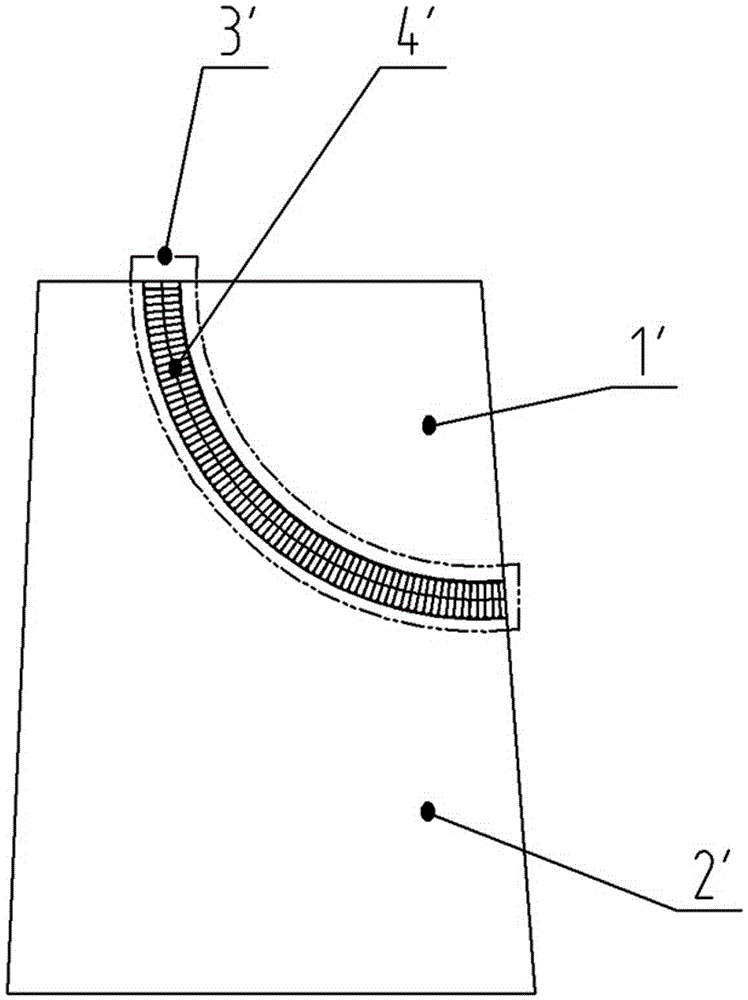

[0028] Embodiment 3: see figure 2 , among the figure, a kind of pocket cushion bottom comprises small doily 1 ' and big lining 2 ', and the line type that is relatively connected at the splicing part 3 ' of small doily and big lining is the sewing line type 4 ' of interlock sewing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com