Hemispherical mobile house

A prefabricated house, hemispherical technology, applied in the direction of arched structure, dome structure, building components, etc., can solve the problems of unbearable external pressure, cumbersome construction, lack of aesthetic feeling, etc., to achieve reasonable and uniform external force and construction span Large and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

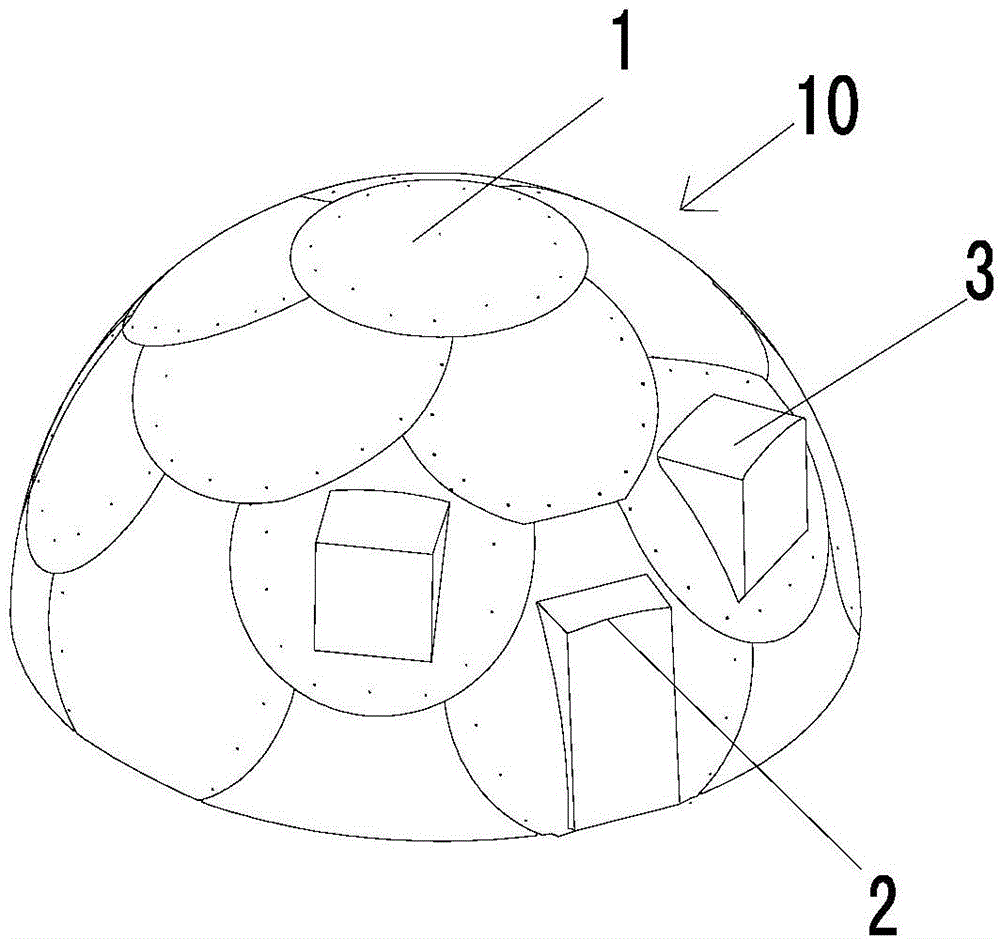

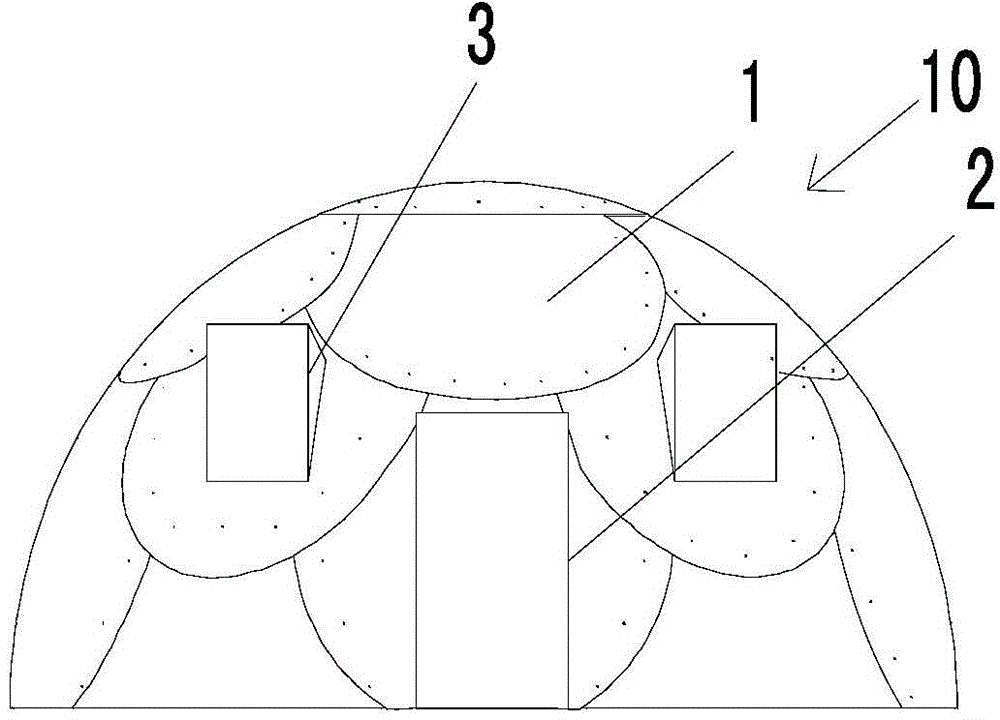

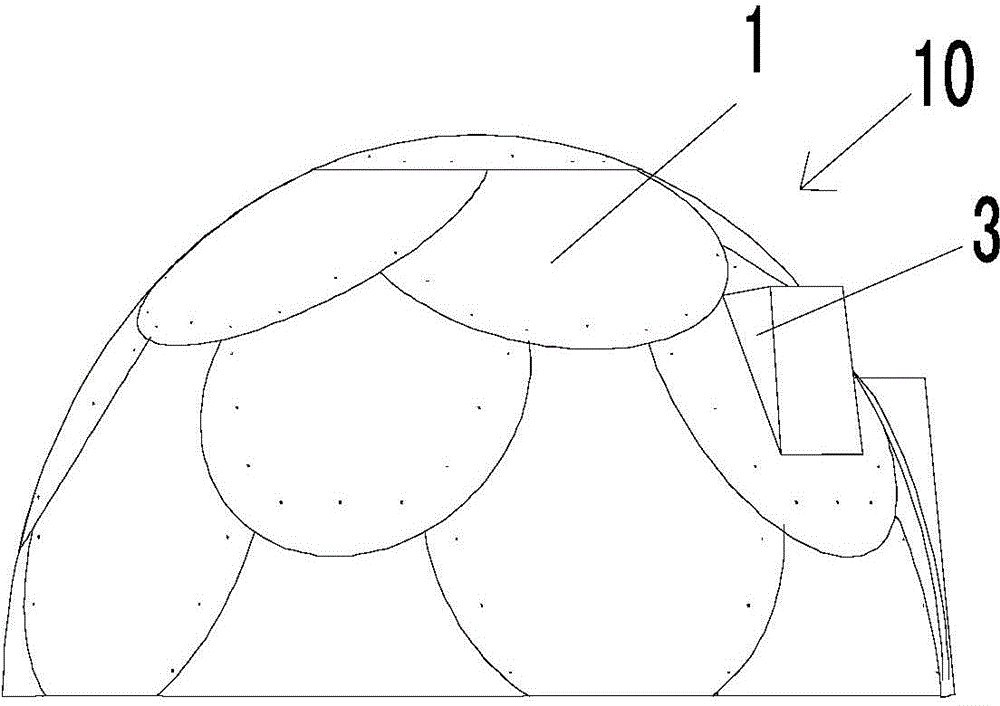

[0030] Such as Figure 1-6 , the prefabricated house 10 of this embodiment includes several prefabricated panels 1 , door prefabricated parts 2 and window prefabricated parts 3 with uniform shapes.

[0031] The shape of the prefabricated panel 1 is a circular spherical surface, an elliptical spherical surface, a semicircular spherical surface, a semi-elliptical spherical surface, a rectangular spherical surface, a trapezoidal spherical surface, a pentagonal spherical surface, a hexagonal spherical surface or a hexagonal spherical surface. An example is preferably a circular sphere.

[0032] The prefabricated panel, door and window prefabricated parts are preferably made of glass fiber hand lay-up molding process or compression molding process (that is, glass fiber reinforced plastic material), or plastic injection molding such as PC and PV.

[0033] The above-mentioned prefabricated house 10 is a hemispherical wall formed by splicing several prefabricated panels 1 in sequence...

Embodiment 2

[0036] The present embodiment has the following modifications on the basis of Embodiment 1:

[0037] A kind of prefab house 10 of above-mentioned embodiment 1, its inner wall is close to be equipped with guard net cover 5; Described guard net cover 5 is attached to the prefabricated house inner wall by iron net, is hemispherical net cover, is used for strengthening Activity room strength. Such as Figure 7 shown. The mesh of protective net cover 5 is honeycomb mesh. The stainless steel wire of protective net cover 5 preferably diameter 1-2mm is made.

[0038] Further, a limit ring 4 is closely attached to the periphery of the bottom of the movable room; the limit ring 4 is made of a steel pipe or glass fiber reinforced plastic material or concrete, and is used to provide circumferential restrictions on the periphery of the bottom circumference to prevent the bottom of the movable room from Peripheral collapse increases the strength of the activity room. Such as Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com