Design Method of Turnable Guide Vane in Axial Flow Compressor

A technology of an axial flow compressor and a design method, which is applied to mechanical equipment, components of a pumping device for elastic fluids, machines/engines, etc., can solve the problems of complex regulation and control, complicated design and manufacture, etc. , The effect of reducing design and manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

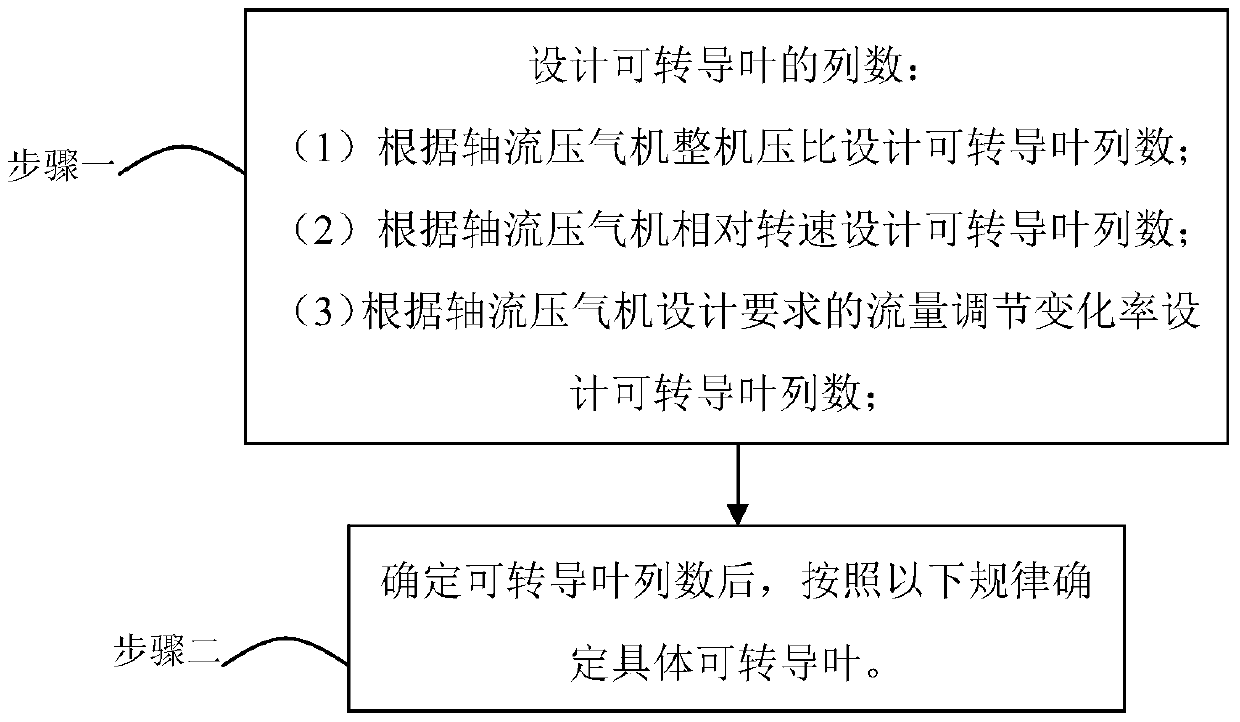

[0042] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0043] The design method of the transmissible guide vane in the axial flow compressor described in this embodiment includes the following steps:

[0044] Step 1. Design the number of columns of transducible leaves:

[0045] From the perspective of start-up acceleration and anti-surge, it is most effective to choose the first few stages of guide vanes to be rotatable; consider the following aspects;

[0046] (1) According to the overall pressure ratio of the axial flow compressor, the number of transmissible vane rows is designed:

[0047] Design the number of transducable vane rows according to the law that the number of transducible vane rows increases with the increase of the pressure ratio of the axial flow compressor;

[0048] (2) According to the relative rotational speed of the axial flow compressor, the number of transformable vane rows is designed:

[0049] According to the rul...

specific Embodiment approach 2

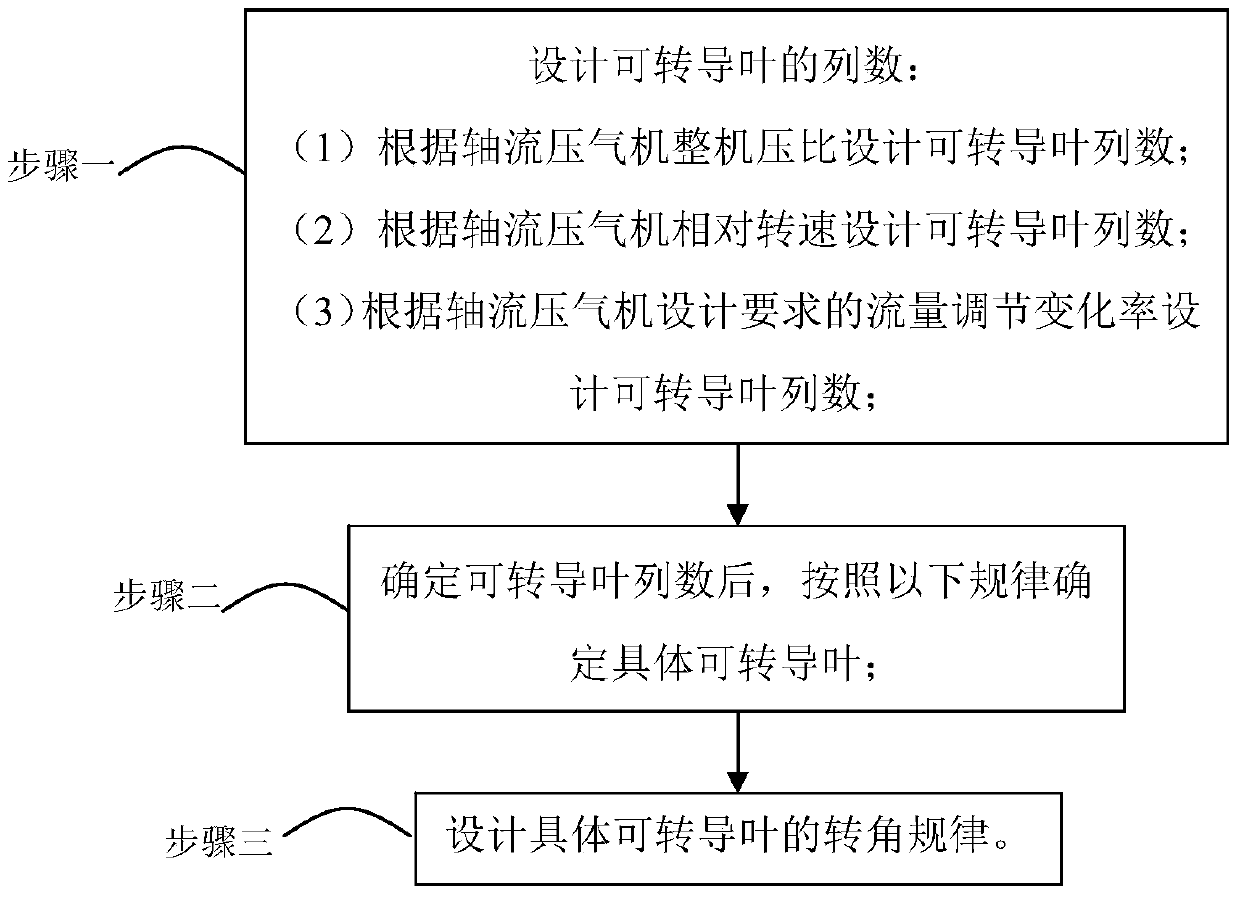

[0062] Specific implementation mode two: combination figure 2 To describe this embodiment,

[0063] The design method for the transmissible guide vane in the axial flow compressor described in this embodiment also includes the following steps:

[0064] Step 3. Design the rotation angle law of the specific transducible vane:

[0065] When the design of two rows of guide vanes can be rotated, that is, the design inlet and the first stage can be rotated; the law of lowering is adopted;

[0066] When the three rows of guide vanes are designed to be rotatable, that is, the design inlet, 1st stage, and 2nd stage are rotatable; the law of lowering is adopted;

[0067] When the four rows of guide vanes are designed to be rotatable, that is, when the design inlet, 1st stage, 2nd stage, and 3rd stage are rotatable; use the rule of lowering or flat adjustment;

[0068] When the five rows of guide vanes are designed to be rotatable, that is, when the inlet, 1st, 2nd, 3rd, and 4th stag...

specific Embodiment approach 3

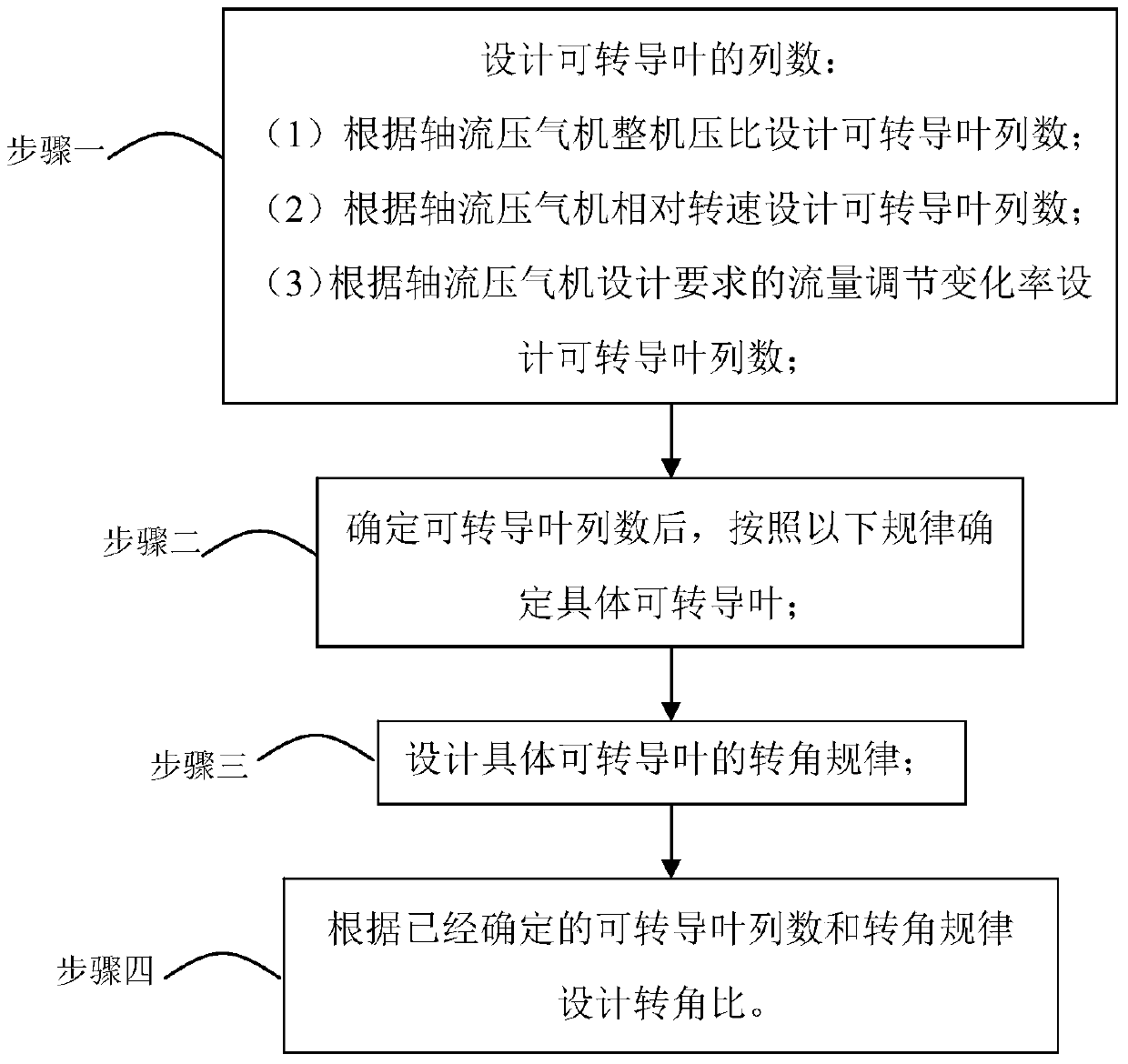

[0076] Specific implementation mode three: combination image 3 To describe this embodiment,

[0077] The design method for the transmissible guide vane in the axial flow compressor described in this embodiment also includes the following steps:

[0078] Step 4. Design the rotation angle ratio according to the determined number of transducible vane rows and the rotation angle law:

[0079] (1-1) When the two rows of guide vanes are rotatable and the down-regulation rule is adopted: the turning angle ratio of the inlet turning guide vanes is 1.0, and the turning angle ratio of the first-stage turning guiding vanes is 0.90-0.97;

[0080] (1-2) When the three rows of guide vanes are rotatable and the down-regulation rule is adopted: the rotation angle ratio of the inlet transmissible vanes is 1.0, the rotation angle ratio of the first-stage transducible vanes is 0.90-0.97, and the second-stage transmissible vanes The corner ratio is 0.80-0.94;

[0081] (1-3) When the four rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com