Closed Disc Spring Assembly Rolled Tube Gear Coupling

A gear coupling and disc spring technology is applied in the field of drum gear couplings to achieve the effects of reasonable design elasticity, improved overall service life and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

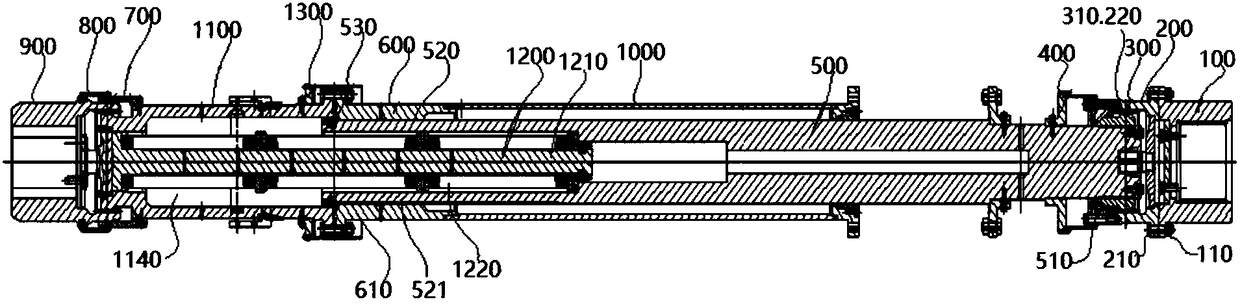

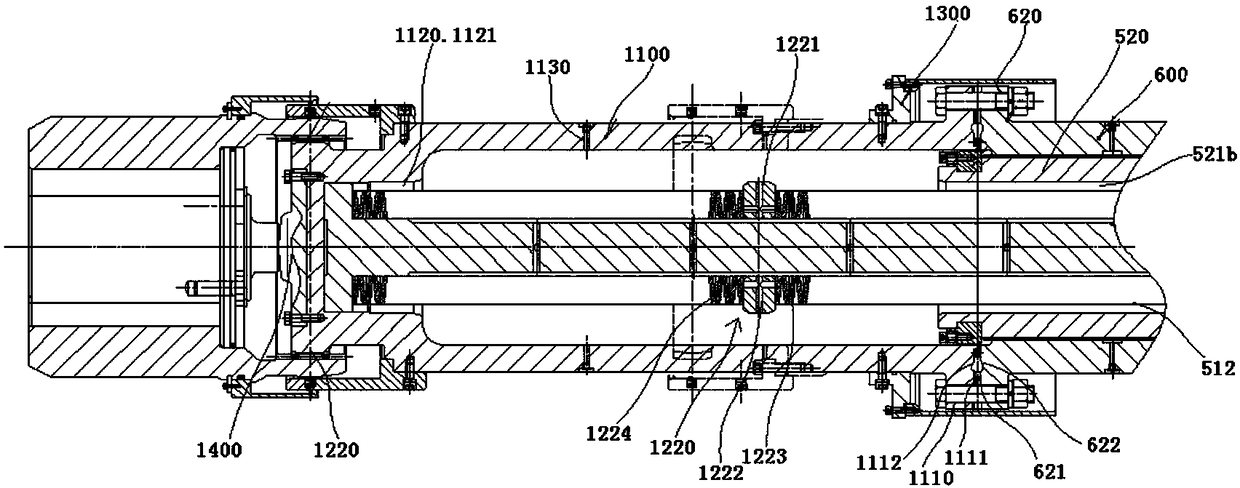

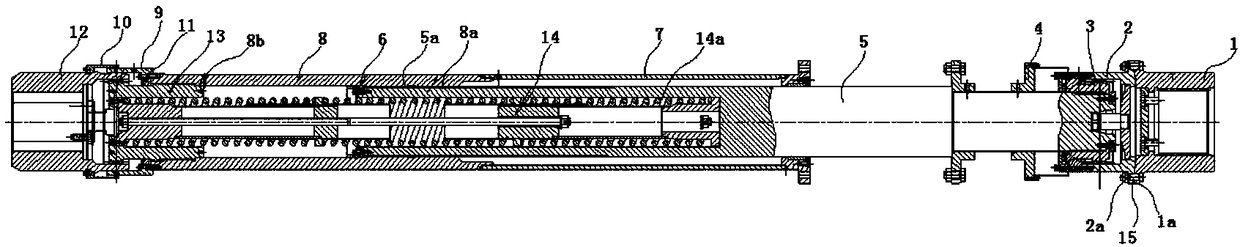

[0032] see figure 1 and figure 2 , the closed disc spring assembly rolling tube gear coupling shown in the figure includes the main shaft end shaft sleeve 100, the main shaft end flange inner gear sleeve 200, the main shaft end external gear 300, the main shaft end waterproof sleeve 400, and the external spline Intermediate shaft 500, inner spline intermediate sleeve 600, roll end waterproof inner cover 700, roll end waterproof outer cover 800, roll end sleeve with internal gear 900, external spline intermediate shaft flange waterproof cover 1000, flange outer gear sleeve 1100 and disc spring assembly 1200.

[0033] The flange 110 on the shaft sleeve 100 at the main shaft end and the flange 210 in the flange inner gear sleeve 200 at the main shaft end are connected by fasteners such as bolts and nuts, and the external gear 300 at the main shaft end is keyed on the main shaft end of the external spline intermediate shaft 500 510, the external teeth 310 of the external gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com