Novel remote control method of pneumatic air valve

A technology of remote control and air valve, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems that the air source power supply cannot maintain the opening and closing position of the air valve, and cannot be chained with the fan to control the operation, so as to achieve protection and control accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

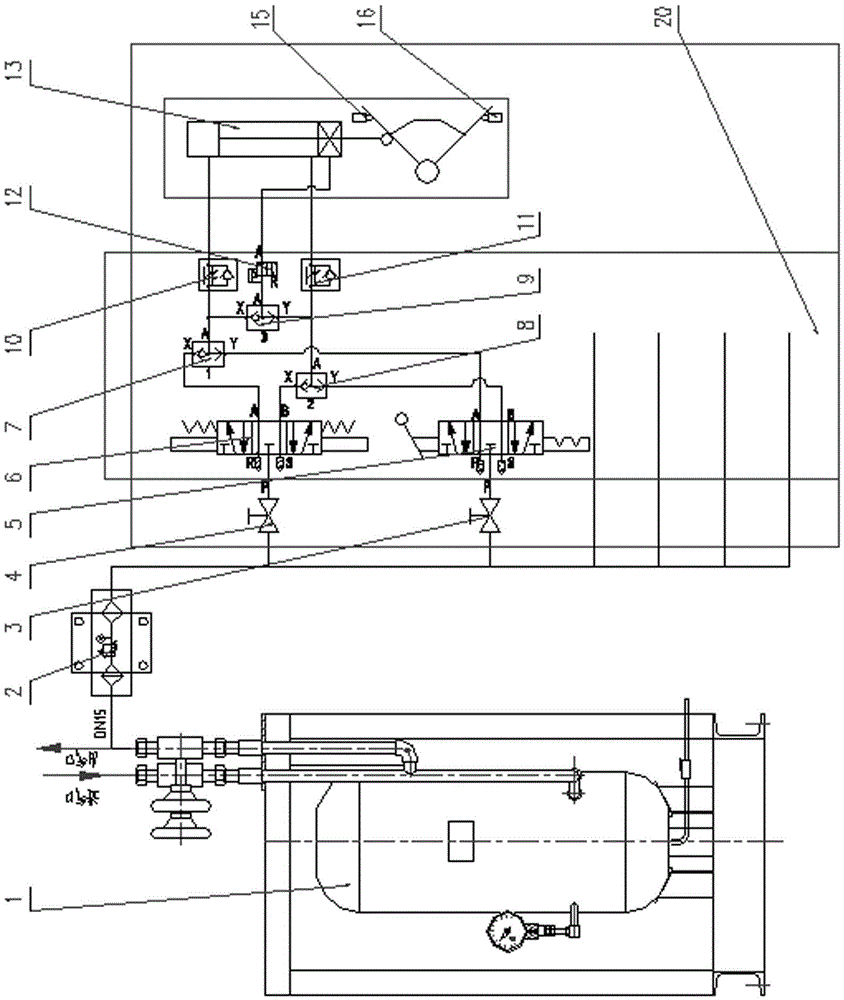

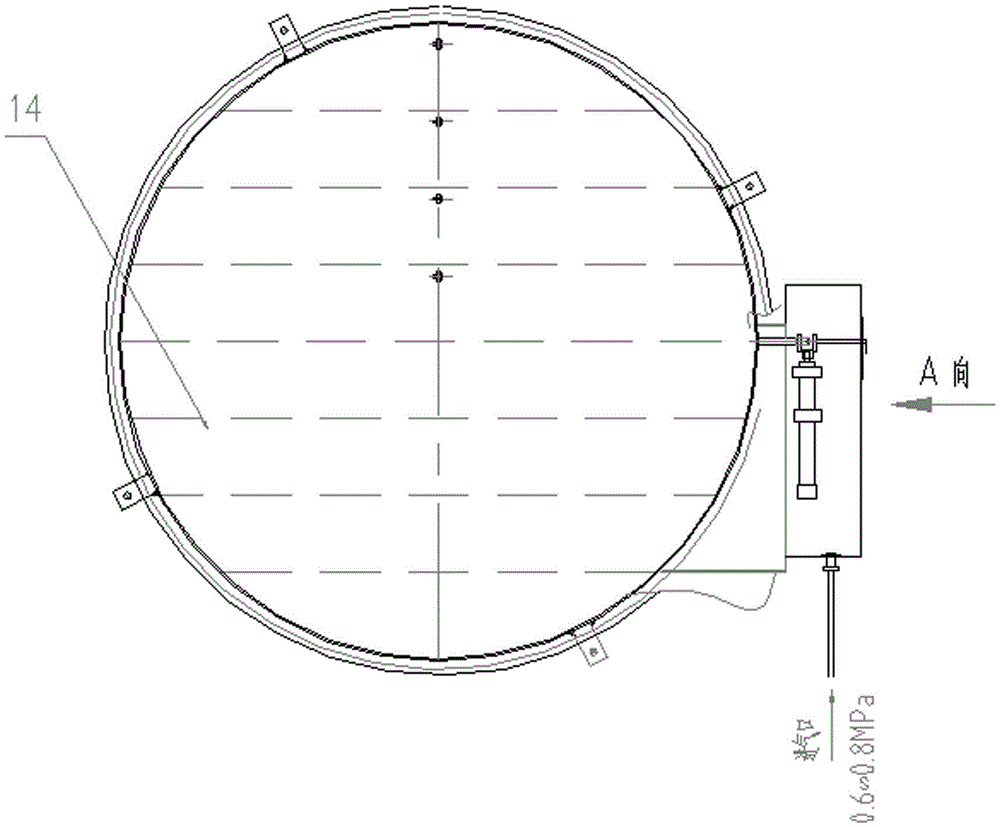

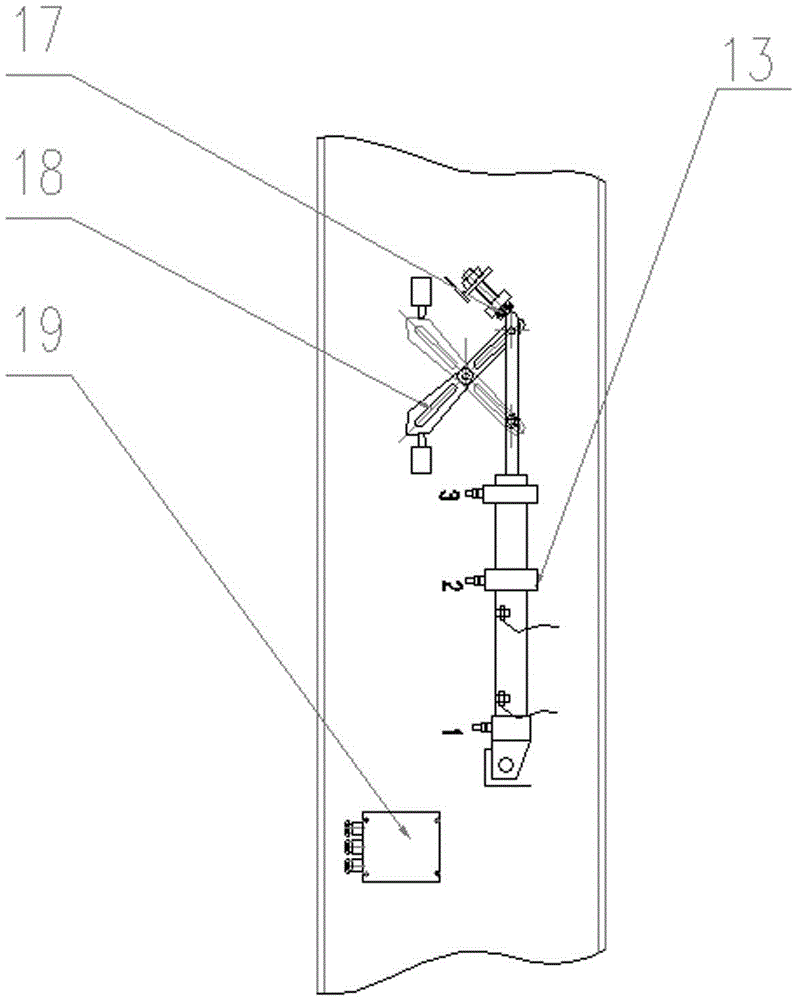

[0036] Further description will be made below in conjunction with the accompanying drawings.

[0037] Figure 1-3 Shown: A new air valve remote control device includes air cylinder 1, pneumatic triple piece 2, manual stop valve 3, electric stop valve 4, three-position five-way hand valve 5, three-position five-way solenoid valve 6, the first shuttle Valve 7, second shuttle valve 8, locking shuttle valve 9, first throttle valve 10, second throttle valve 11, two-position three-way air control valve 12, locking cylinder 13, closing travel switch 15, opening travel switch 16. Nylon stop block 17, lever 18 and junction box 19.

[0038]The air bottle 1 is connected to the manual shut-off valve 3 and the electric shut-off valve 4 respectively in two ways through the pneumatic triple unit 2. Air ports A and B are respectively connected to the first shuttle valve 7-air inlet Y and the second shuttle valve 8-air inlet Y, and the two air outlets A and B of the three-position five-way s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com