QT-based cross platform PLC product tool test system and test method thereof

A test system and test method technology, applied in the field of PLC detection, can solve problems such as heavy workload, inaccurate test results, and low test accuracy, and achieve the effects of reducing workload, automatically testing test results, and overcoming bad effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

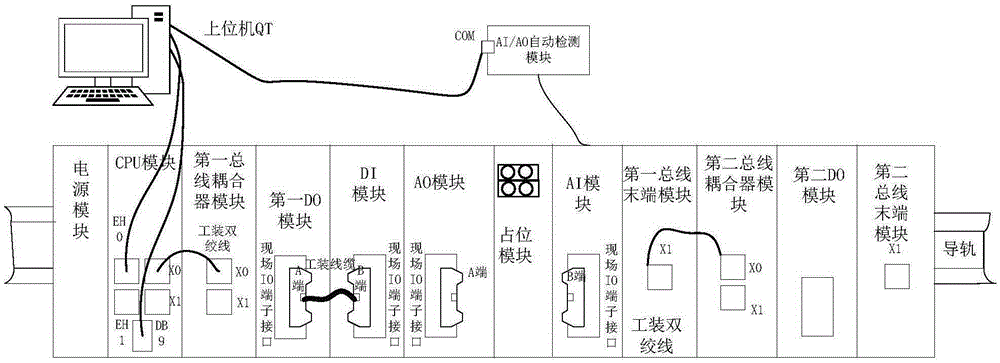

Embodiment 1

[0064] like figure 1 Shown in detail, the present invention provides a kind of QT-based cross-platform PLC product tooling test system, including power module, CPU module, first bus coupler module, first DO module, DI module, interconnected in order on the guide rail, AO module, occupancy module, AI module, first bus end module, second bus coupler module, second DO module and second bus end module, the EH0 of the CPU module is connected with the host computer to realize data transmission through ETH0 The protocol is based on EtherCAT, the host computer is connected to the AI / AO automatic test module, the AI / AO automatic test module is connected to the AI module, and the first bus end module is connected to the second bus coupler module through a tooling twisted pair , the A end of the first DO module is connected to the B end of the DI module through a tooling cable, the first DO module, DI module, AO module and AI module are respectively provided with field IO terminal inte...

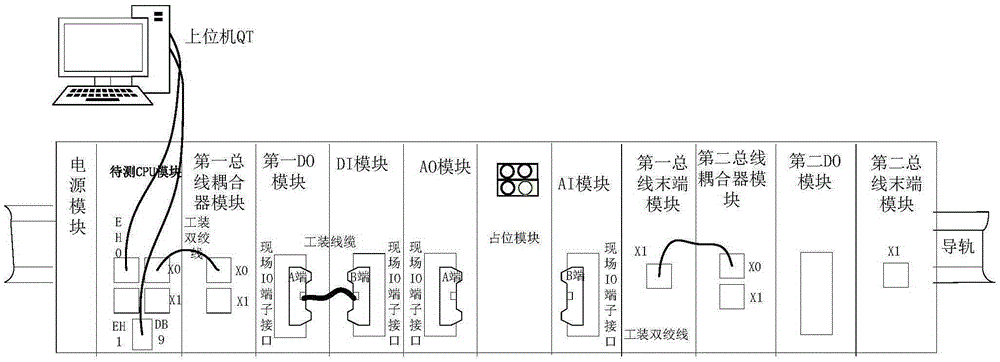

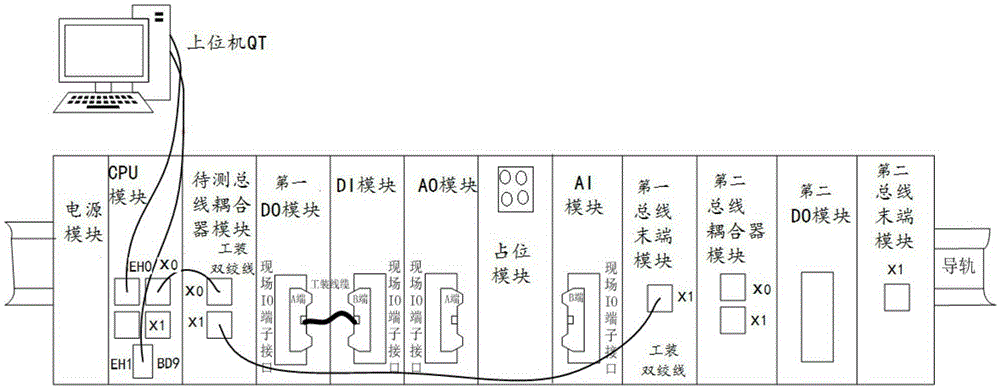

Embodiment 2

[0066] like Figures 2 to 13 Shown, the present invention also provides the test method of the cross-platform PLC product tooling test system based on QT, and described test method comprises CPU module detection step:

[0067] Step 1. Connect one end of the tooling cable to the CPU module DB9 interface, and the other end to the host computer. After the test system is connected, check the serial port on the CPU module, and open the .exe program of the PLC test tooling system from the host computer to select CPU module test item, the CPU module is checked, and the test item includes a serial port test, and the serial port test includes 4 test items for user RS232, DSU, OS_DEBUG, Comx four channel tests;

[0068] The inspection method of step 2, described four channel tests comprises:

[0069] 1) DSU: Use the tooling test system to connect to the target board to judge whether the DSU is working normally;

[0070] 2) OS_DEBUG: The user program download port is in the RS operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com