A kind of multi-rare earth phase material and preparation method thereof

A technology of rare earth and permanent magnet materials, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem of insufficient magnetic energy product, achieve the effects of improving the environment, flexible composition ratio, and high social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

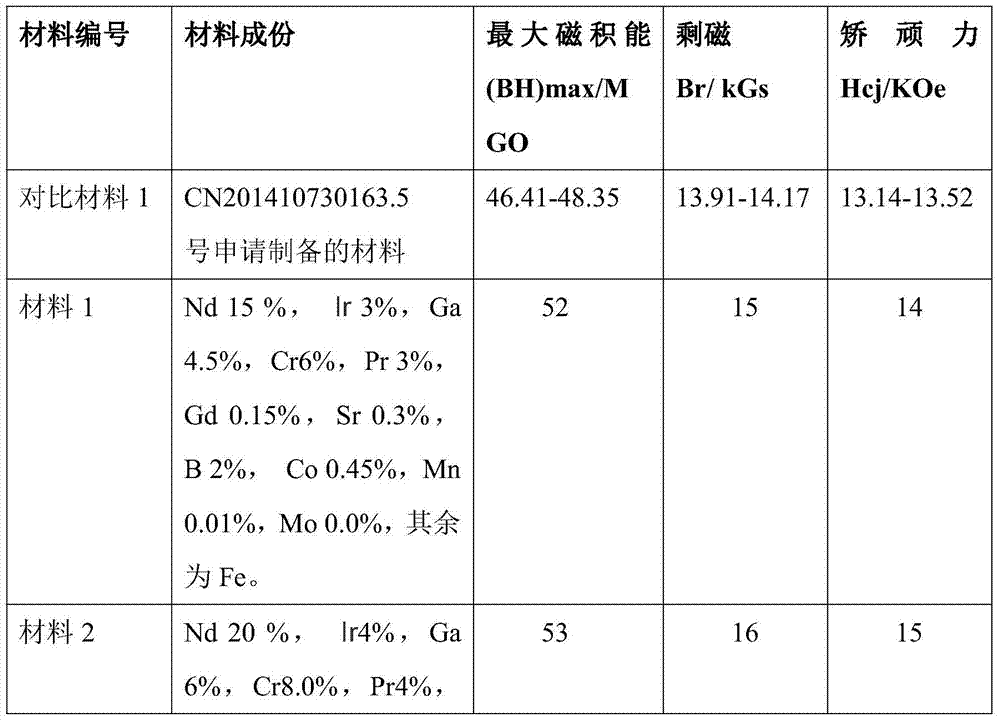

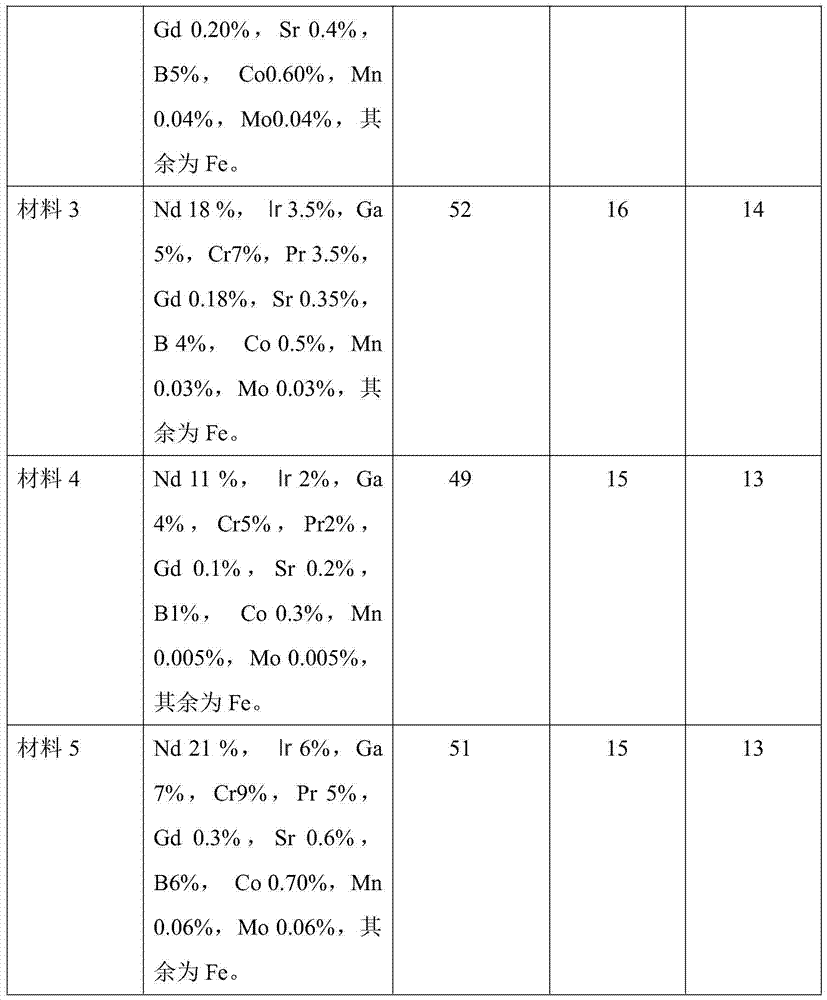

Embodiment 1

[0019] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0020] 1) Dosing according to the following mass percentages: Nd 15%, Ir 3%, Ga 4.5%, Cr 6%, Pr 3%, Gd 0.15%, Sr 0.3%, B 2%, Co 0.45%, Mn 0.01%, Mo 0.0%, the rest is Fe;

[0021] 2) Add the above-mentioned prepared raw materials into the crucible of the vacuum induction furnace, heat up to 1560-1580°C, the vacuum degree of the vacuum induction furnace is required to be less than 0.1Pa, keep it warm for 20-30 minutes, pour it into the ingot mold, and cool naturally to obtain Multi-rare-earth phase permanent magnet material alloy ingot; after making strips, the above-mentioned multi-rare-earth phase material alloy strips are powder-milled, pressed and formed, and sintered to obtain the multi-rare-earth phase permanent magnet material. When making strips, the obtained multi-rare-earth phase permanent magnet material alloy ingot is put into a remelting tubular crucible in a vacuu...

Embodiment 2

[0023] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0024] 1) Dosing according to the following mass percentages: Nd 20%, Ir4%, Ga 6%, Cr8.0%, Pr4%, Gd0.20%, Sr 0.4%, B5%, Co0.60%, Mn 0.04%, Mo0 .04%, the balance being Fe;

[0025] 2) Add the above-mentioned prepared raw materials into the crucible of the vacuum induction furnace, heat up to 1560-1580°C, the vacuum degree of the vacuum induction furnace is required to be less than 0.1Pa, keep it warm for 20-30 minutes, pour it into the ingot mold, and cool naturally to obtain Multi-rare-earth phase permanent magnet material alloy ingot; after making strips, the above-mentioned multi-rare-earth phase material alloy strips are powder-milled, pressed and formed, and sintered to obtain the multi-rare-earth phase permanent magnet material. When making strips, the obtained multi-rare-earth phase permanent magnet material alloy ingot is put into a remelting tubular crucible in a vacu...

Embodiment 3

[0027] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0028] 1) Dosing according to the following mass percentage: Nd 18%, Ir 3.5%, Ga 5%, Cr 7%, Pr 3.5%, Gd 0.18%, Sr 0.35%, B 4%, Co 0.5%, Mn 0.03%, Mo 0.03 %, the rest is Fe;

[0029] 2) Add the above-mentioned prepared raw materials into the crucible of the vacuum induction furnace, heat up to 1560-1580°C, the vacuum degree of the vacuum induction furnace is required to be less than 0.1Pa, keep it warm for 20-30 minutes, pour it into the ingot mold, and cool naturally to obtain Multi-rare-earth phase permanent magnet material alloy ingot; after making strips, the above-mentioned multi-rare-earth phase material alloy strips are powder-milled, pressed and formed, and sintered to obtain the multi-rare-earth phase permanent magnet material. When making strips, the obtained multi-rare-earth phase permanent magnet material alloy ingot is put into a remelting tubular crucible in a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com