Air-flow type deep-plowing and deep-fertilizing system

An air-flow type and deep loosening technology, which is applied in the direction of fertilization device, application, fertilizer distributor, etc., can solve the problems of powdery solid fertilizer, powdery fertilizer cannot be transported, and the transportation volume is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

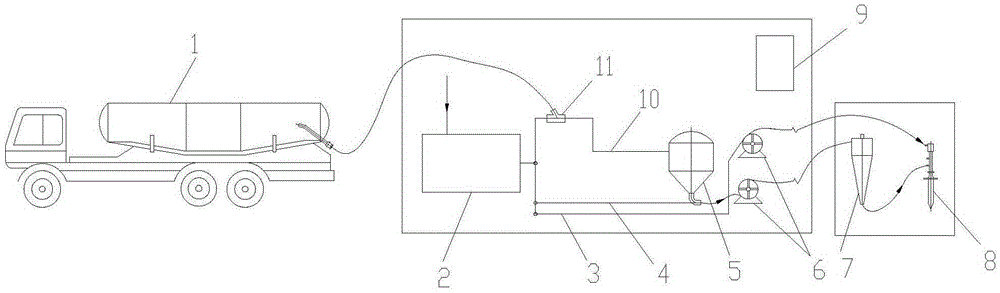

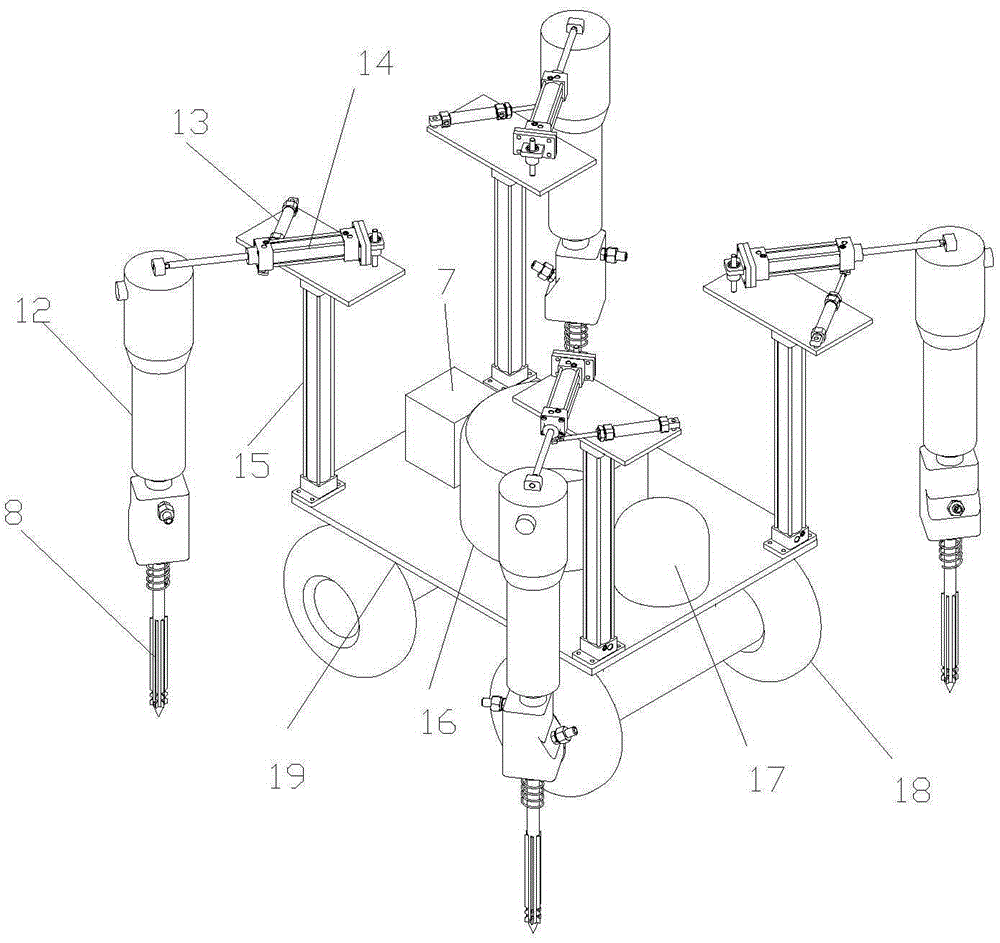

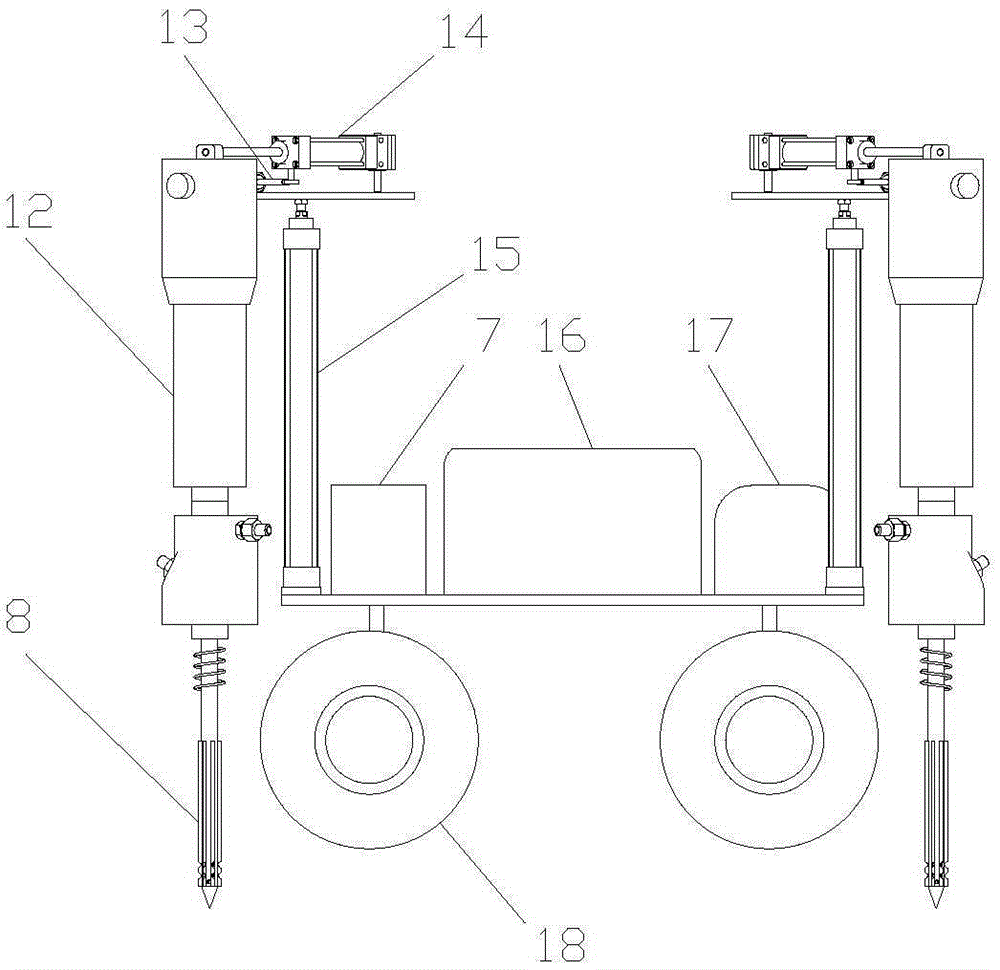

[0021] figure 1 It is a connection schematic diagram of the present invention; figure 2 It is the axonometric drawing of the loosening operation vehicle of the present invention;

[0022] image 3 It is the front view of the loosening operation vehicle of the present invention; Figure 4 for image 3 The top view; As shown in the figure, the airflow type deep loosening and deep application system of the present embodiment includes loosening operation gun 8 and the airflow type powder particle that is used to transport powder fertilizer to the fertilizer inlet of described loosening operation gun 8 Fertilizer supply device, the airflow powder fertilizer supply device includes an air compressor 2 and a primary feed pipe 10 connected to the air outlet of the air compressor 2, the primary feed pipe 10 is provided with a venturi The feeder 11 of structural suction, the feeder 11 has a flow channel of Venturi structure and connects the flow channel to the primary delivery pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com