A process device and method for recovering cold energy from lng produced from coke oven gas

A technology for coke oven gas and process equipment, which is applied in refrigeration and liquefaction, cold treatment separation, liquefaction and other directions, can solve the problem of reducing the power consumption utilization rate of refrigerant compressor units, and achieves reduction of total project investment, reduction of floor space, Increase the effect of localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

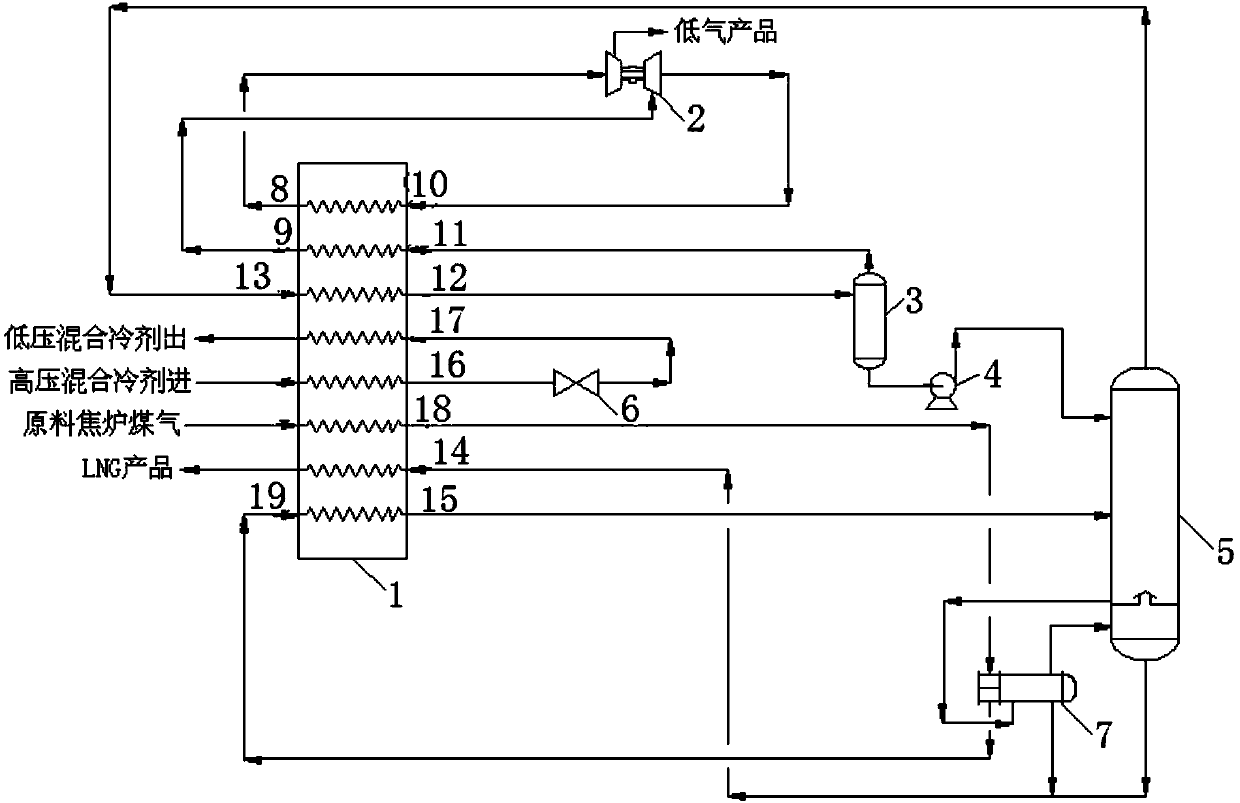

[0010] A process device for recovering cold energy from coke oven gas to LNG, such as figure 1 As shown, it includes: heat exchanger 1, coaxial compression expander 2, liquid separation tank 3, LNG return pump 4, dehydrogenation tower 5, throttle valve 6, reboiler 7, etc., wherein:

[0011] The first outlet 8 of the heat exchanger 1 is connected to the inlet of the compression end of the coaxial compression expansion machine 2, the second outlet 9 of the heat exchanger 1 is connected to the inlet of the expansion end of the coaxial compression expansion machine 2, and the coaxial compression expansion machine 2 The outlet of the expansion end of the heat exchanger 1 is connected to the first cold flow channel 10; the third outlet 12 of the heat exchanger 1 is connected to the inlet of the liquid separator tank 3, and the gas phase outlet of the liquid separator tank 3 is connected to the outlet of the heat exchanger 1. The second cold flow channel 11 is connected, the liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com