Step-type self-flow separation layer grouting filling treatment gangue pulping and slurry conveying process

A step-type, pulp delivery technology, which is applied to filling materials, safety devices, mining equipment, etc., can solve the problems of self-flow, continuous, buffering and quantification in the pulping process, inability to effectively connect process links, and inability to solve long-distance transportation, etc. To achieve the effect of realizing green mining, solving the problem of long-distance transportation, and solving the problem of gangue treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

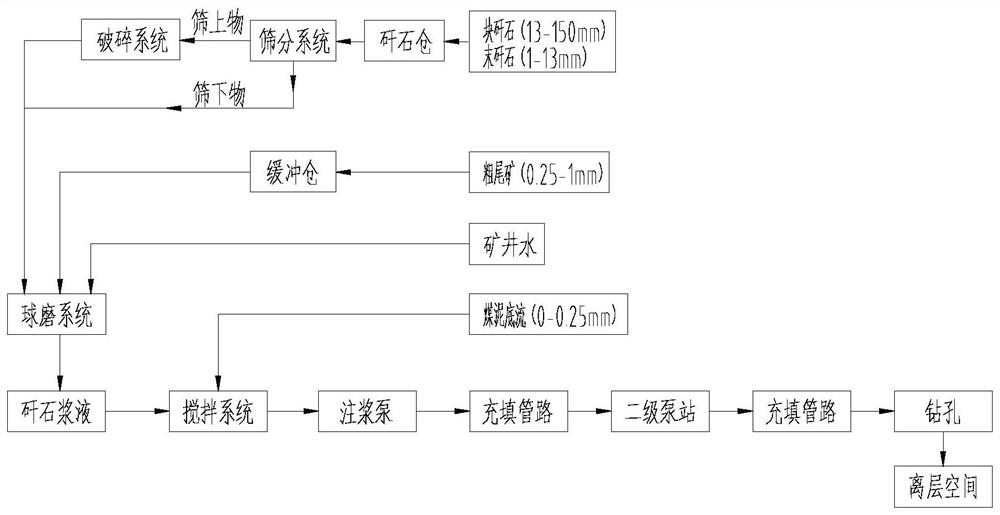

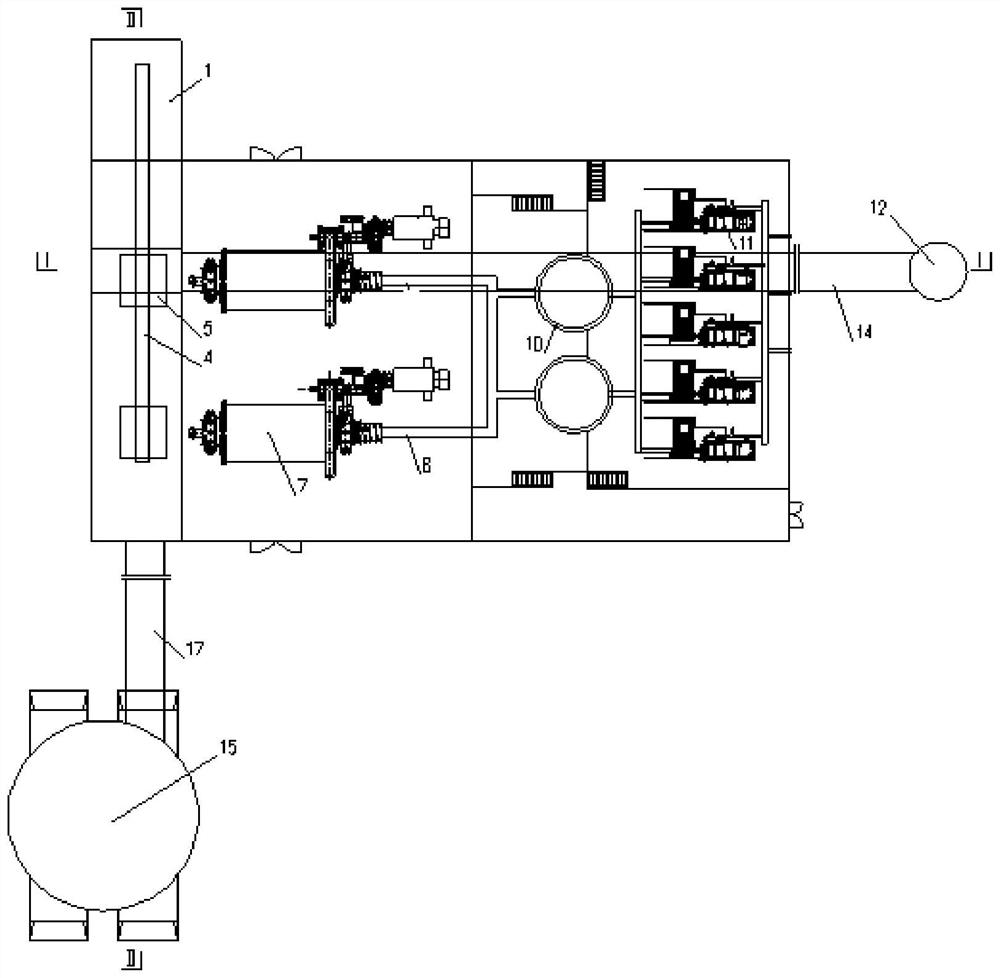

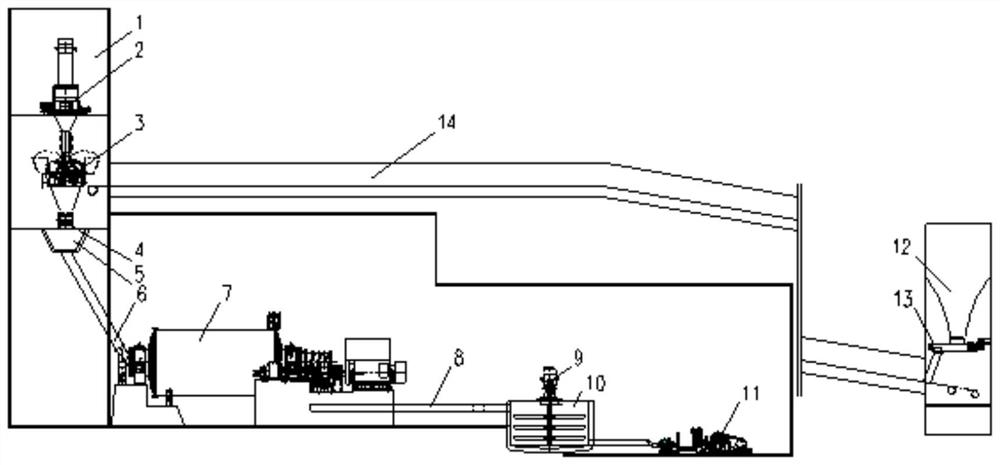

[0028] Such as Figure 1-Figure 4 Shown is a step-type self-flowing type separation layer grouting filling process for gangue pulping and conveying process. The process is realized based on a pulping and conveying process system. The pulping and conveying process system includes screening and crushing station 1, screening and crushing station 1 is installed with an iron remover 18, the first layer below the iron remover 18 is provided with a cross screen 2, and the second layer below the cross screen 2 is provided with a crusher 3, and the third layer below the crusher 3 is provided with a scraper. The plate conveyor 4 and the bottom of the scraper conveyor 4 are provided with several groups of feeding bins 5, and the bottom of the feeding bins 5 is connected with the ball mill 7 through the chute 6, and the bottom of the discharge port of several groups of ball mills 7 is provided with flow slurry Groove 8, and one end of the headstock tank 8 is provided with a buffer pool 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com