Jinhua fungus Tianjian tea bag and processing method thereof

A processing method and tea bag technology, applied in the field of tea bag and its processing, can solve the problems of insufficient transformation of contents, inconvenient brewing, slow leaching of tea juice, etc., and achieve fast leaching of tea juice and full transformation , soup color bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

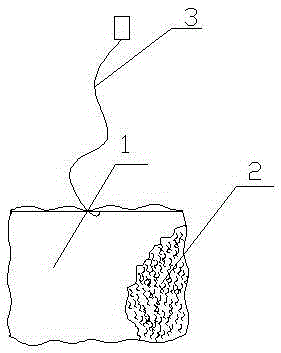

[0025] Example 1: Jinhua Tianjian teabag, including bubble bag 1, Tianjian 2 is installed in the bubble bag, said Tianjian 2 is fermented with raw tea→lighting the tea ingredients→sorting the tea ingredients→mixing the tea ingredients Mixing→sterilizing piles→steaming tea→packing baskets→pressing baskets→drying→adding tea juice→piling→re-sterilizing piles→steaming tea→building→blooming→drying→deblocking→sieving→drying to enhance aroma→packing The golden flower sky tip made by the process.

Embodiment 2

[0026] Example 2: The processing method of Jinhua Tianjian teabag adopts the following technological process: raw tea fermentation→tea material lighting→tea material sorting→tea material blending→sterilization and stacking→steaming tea→packing baskets→pressing baskets→ Drying → adding tea juice → stacking → sterilizing and fertilizing → steaming tea → brewing → blooming → drying → deblocking → sieving → drying to enhance aroma → packaging.

Embodiment 3

[0027] Embodiment 3: according to embodiment 1 or embodiment 2 exemplified Jinhua Tianjian teabag and the fermenting of raw tea described in its processing method, the following steps can be adopted successively:

[0028] a. Feeding into piles: According to the quantity of each batch of fermented tea materials, the materials are fed at one time, piled up into a pile of appropriate height, and the tea materials can be turned from the bottom to the top with a rake. The height of the pile may be 30-60 cm, preferably 40-55 cm, 45-50 cm.

[0029] b. Sprinkling of tea materials: Sprinkle the piles of tea materials several times, and turn them once after sprinkling, so that the moisture content of the tea materials reaches 20%-28%. Preferably 22%-26%, 23%-25%, generally sprinkle water 3-4 times.

[0030] c. Fermentation of tea material: After the tea material is sprinkled with water, let the tea material naturally absorb water for 0.5-1.5 hours, or pile up 1-1.5 meters high after 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com