Multifunctional plate bending machine with lifting pressing type pipe bending mechanism

A plate bending machine and pipe bending technology, which is applied to metal rolling mill stands, manufacturing tools, metal rolling racks, etc., can solve the problems of high price, single function, and bulky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

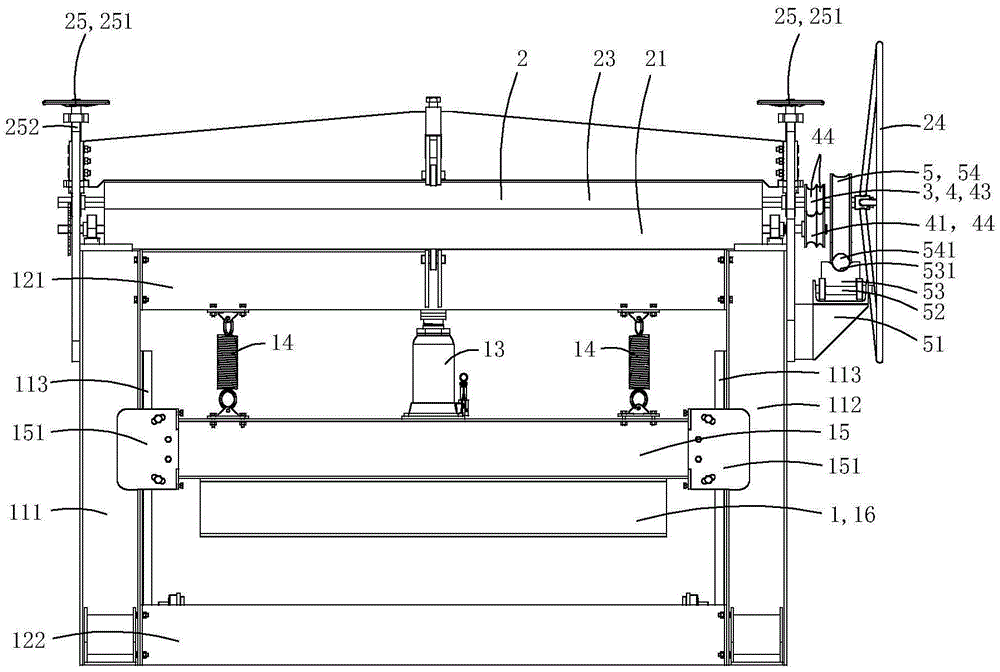

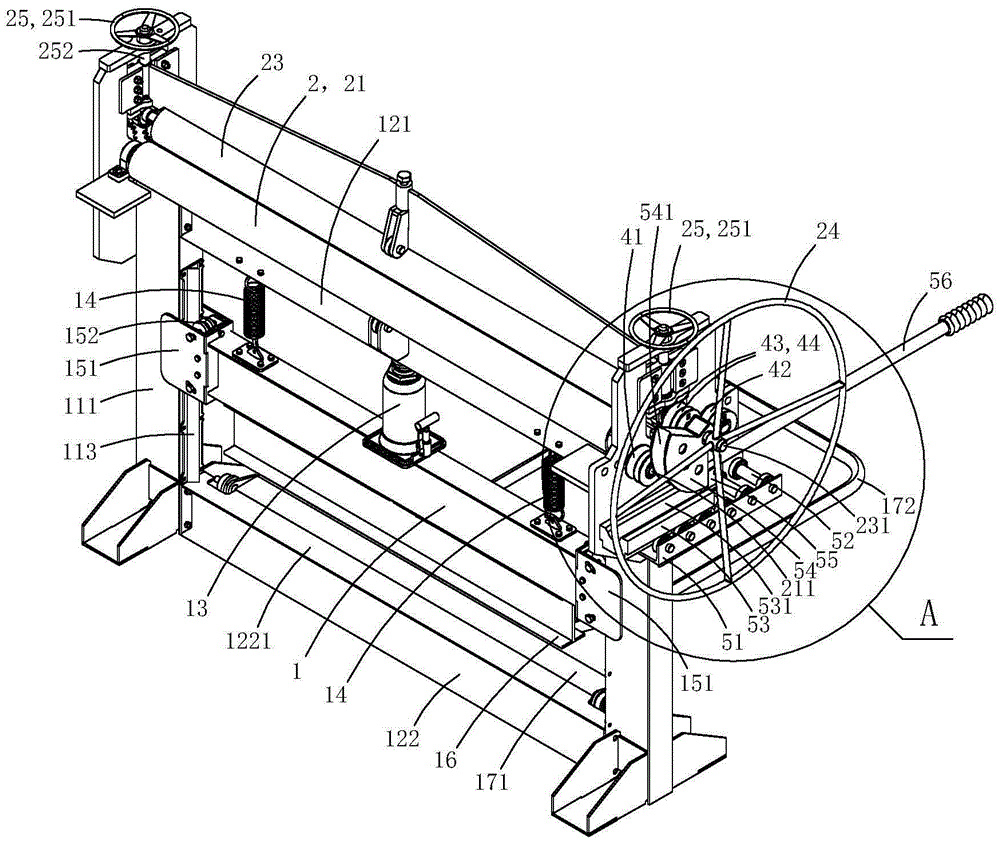

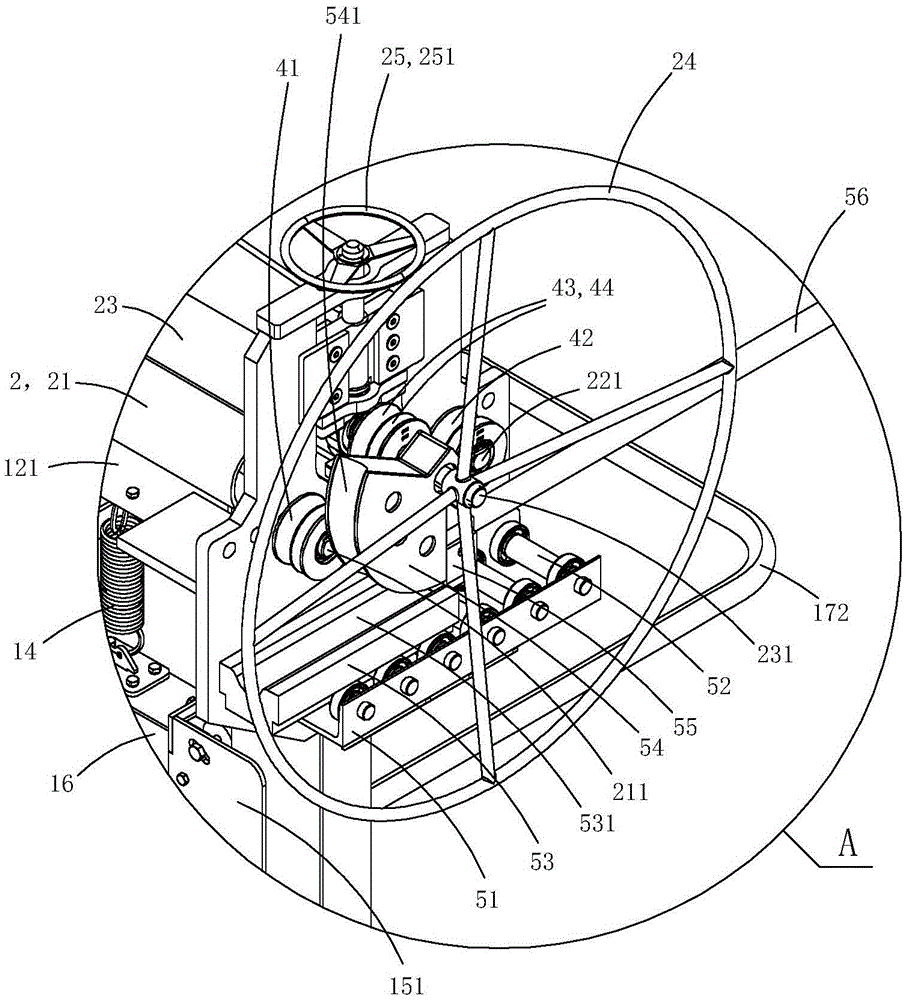

[0015] Figure 1 to Figure 5 A first embodiment of the invention is shown in which, figure 1 It is a structural schematic diagram of the first structure of the present invention; figure 2 yes figure 1 A schematic diagram of a three-dimensional structure of the bending machine shown; image 3 yes figure 2 The partial enlarged schematic diagram of A in the plate bending machine shown; Figure 4 yes figure 1 A schematic diagram of the three-dimensional structure of the bending machine shown when viewed from another angle; Figure 5 yes Figure 4 The partial enlarged schematic diagram of B in the plate bending machine shown.

[0016] This embodiment is a multifunctional plate bending machine, see Figure 1 to Figure 5 As shown, it includes a plate bending mechanism 1, a plate rolling mechanism 2 and a pipe bending mechanism 3; the plate bending mechanism includes a left pillar 111, a right pillar 112, a first horizontal fixed beam 121, a second horizontal fixed beam 122,...

Embodiment 2

[0031] Figure 6 to Figure 8 A second embodiment of the invention is shown, in which Figure 6 It is a structural schematic diagram of the second structure of the present invention; Figure 7 yes Figure 6 A schematic diagram of a three-dimensional structure of the bending machine shown; Figure 8 yes Figure 6 A schematic diagram of the three-dimensional structure of the plate bending machine shown when viewed from another angle.

[0032] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 to Figure 8 As shown, the present embodiment also includes a shearing mechanism 6; the shearing mechanism includes a shearing knife 61 and a shearing auxiliary knife 62, the blade 611 of the shearing knife is V-shaped, and the top wall of the shearing auxiliary knife is provided with The V-shaped edge groove 621 adapted to the blade of the shearing horizontal knife; the shearing horizontal knife 61 is rotatably arranged on the I-beam, and the shearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com