Lathe center

A tip and lathe technology, which is applied in the direction of tailstock / tip, turning equipment, tool holder accessories, etc., can solve the problems of reducing actual work efficiency, inconvenient use, troublesome clamping, etc., and achieve the effect of improving processing speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

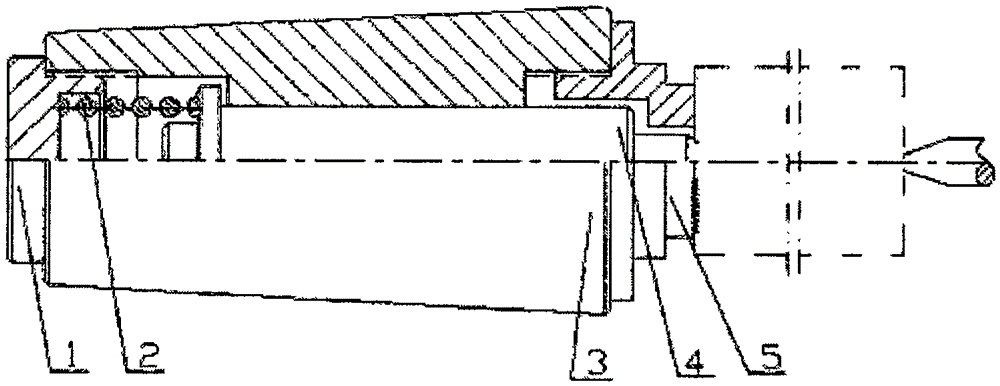

[0008] see figure 1 , a lathe top, including a screw plug 1, a spring 2, a Morse cone 3, a mandrel top 4 and an end-face sharp-toothed claw 5, the screw plug 1 is connected to the left end of the Morse cone 3 in a threaded manner, and the end-face sharp teeth The claw 5 is connected to the right end of the Morse cone 3 in a threaded manner, and the diameter of the right end surface of the toothed claw 5 is 5mm smaller than the diameter of the workpiece, and sharp teeth are set on the end surface, and the inner hole of the Morse cone 3 is movable. The mandrel top 4 is set in the same way, and the spring 2 is pressed between the screw plug 1 and the shoulder of the mandrel top 4 .

[0009] During processing, first insert the Morse cone 3 of the present invention in the lathe spindle hole, then align the center hole of the left end of the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com