A kind of radome structure, its forming method and its mold

A molding method and radome technology, applied in directions such as the radiating unit cover, can solve the problem of not realizing the integration of the radome and the connecting ring, and achieve the effects of improving connection reliability, comprehensive performance, and convenient and reliable fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

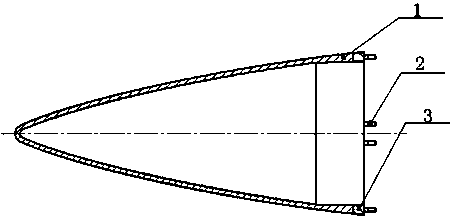

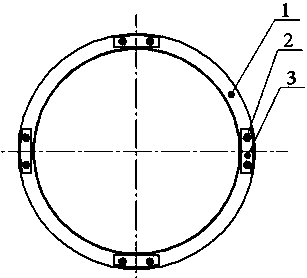

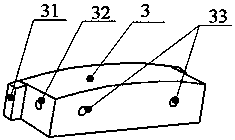

[0058] Such as Figure 1~2 As shown; a radome structure, which is connected to the cabin body, which includes: a cover body 1, which is made of quartz fiber reinforced silicon-containing aryne composite material, prepared by resin transfer molding (RTM); multiple embedded The insert 3 is made of low-expansion alloy steel material, and it is arranged at the root of the cover body 1. It is braided in a quartz fiber reinforcement 4 before forming, and is combined with the cover body 1 after forming. Each of the embedded inserts 3 is provided with threaded holes on the end surface; a plurality of connecting studs 2 are made of high-strength steel, and their two ends are respectively external threads, and one end of each of the connecting studs 2 is externally threaded. The threads are correspondingly fitted in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com