Power source used for electric vehicle

A technology for electric vehicles and power supplies, applied in electric vehicles, emergency power supply arrangements, current collectors, etc., can solve the problems of complicated wiring harness installation, complicated circuit diagrams, etc., to increase the number of charge and discharge cycles, avoid long-term work, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

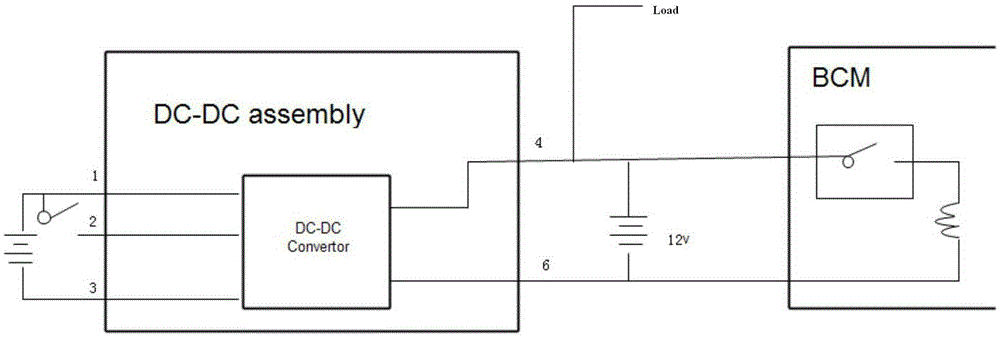

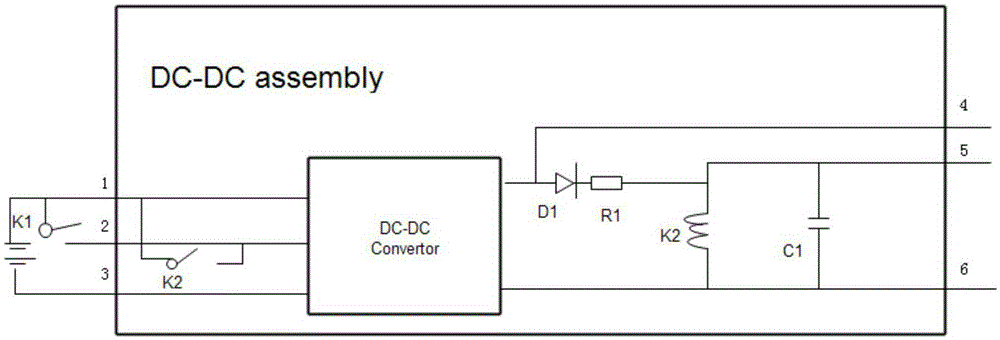

[0029] Such as image 3 As shown, the present invention is a power supply for electric vehicles, including a high-voltage battery V and a DC converter DC-DCassembly, the DC converter includes a power input positive terminal 1, a power input negative terminal 3, and is used to start the DC converter The enabling signal terminal 2 of the high-voltage battery v is electrically connected to the positive terminal 1 of the power input, the negative terminal of the high-voltage battery is electrically connected to the negative terminal 3 of the power input, and the positive terminal of the high-voltage battery is connected to A start control relay K1 is provided between the enabling signal terminals 2, wherein the DC converter DC-DCassembly includes a DC conversion module DC-DCconvertor, an equipment power supply output terminal 4, and a normal power supply output terminal 5. The power output terminal 5 can still provide power for the constant current equipment when the DC-DC convert...

Embodiment 2

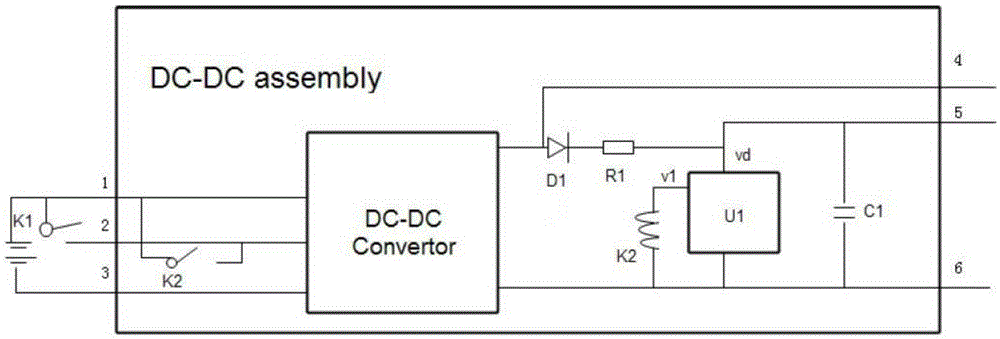

[0041] The difference between this embodiment and the first embodiment above is that a voltage detection unit U1 is further provided between the coil end of the built-in relay K2 and the output end 5 of the normal power supply.

[0042] The working principle of this embodiment:

[0043] The normal power output terminal 5 of the DC converter DC-DC assembly provides normal power for the start switch and alarm of the vehicle.

[0044] Electric vehicle starting state: at this time, the enable signal terminal 2 of the DC converter DC-DCassembly is controlled by high voltage, the DC conversion module DC-DCConvertor is in the working state, and the output terminal 4 of the equipment power supply of the DC converter DC-DCassembly is 12V The equipment provides power and the voltage is Vout; if the voltage of the capacitor C1 is lower than the set minimum working voltage Vout-0.7v, the DC conversion module DC-DCConvertor charges the capacitor C1 to Vc1=Vout-0.7 through the diode D1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com