A kind of anti-scarring adhesion shrink film and its production process and application

A shrink film and adhesion technology, applied in the production process of anti-scar shrink film, anti-scar shrink film, and the field of anti-scar shrink film, can solve the problem of shrink film rolling or wrinkling, unable to separate, shrink film Adhesion and other problems, to achieve the effect of favorable promotion and high aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

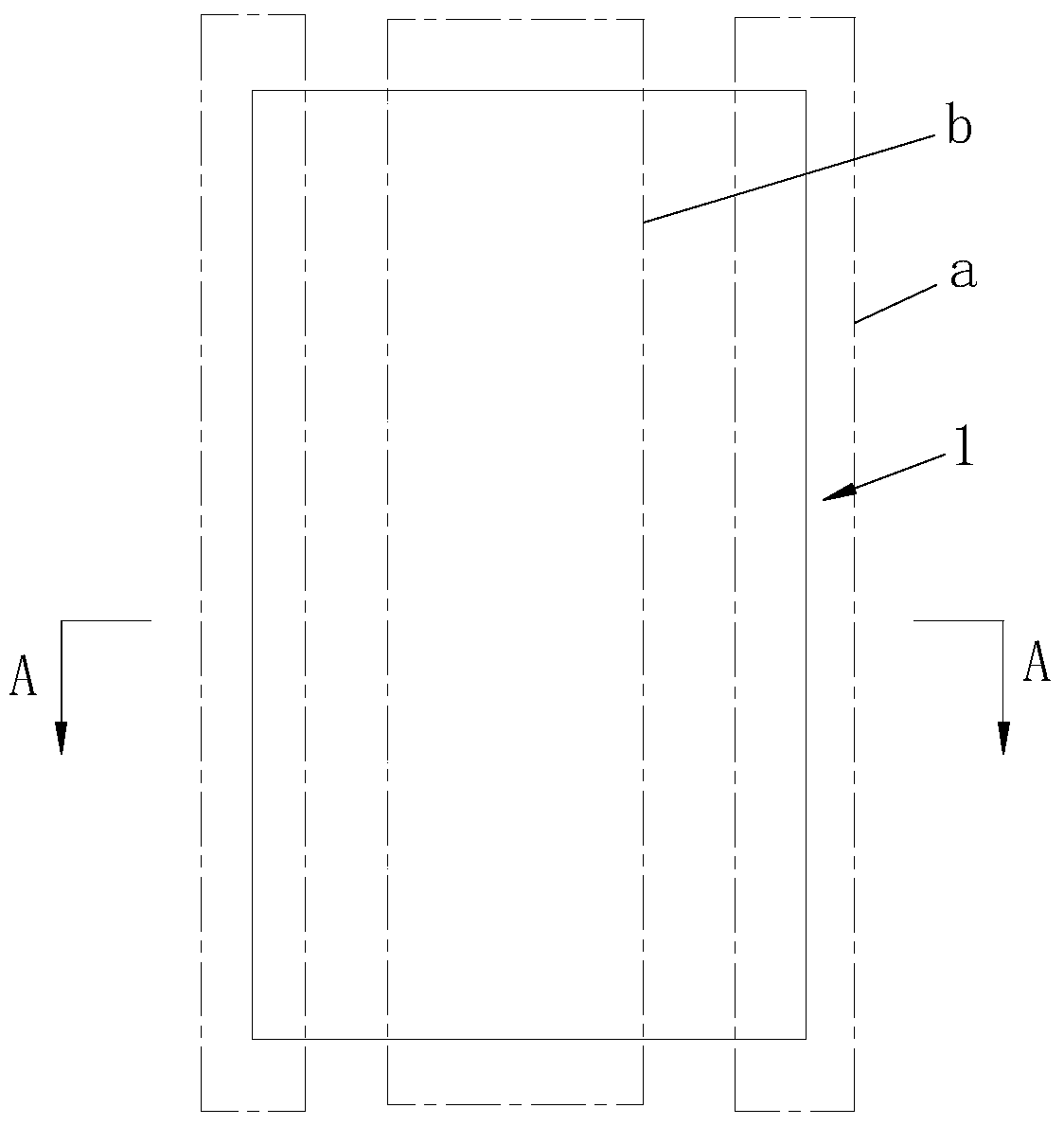

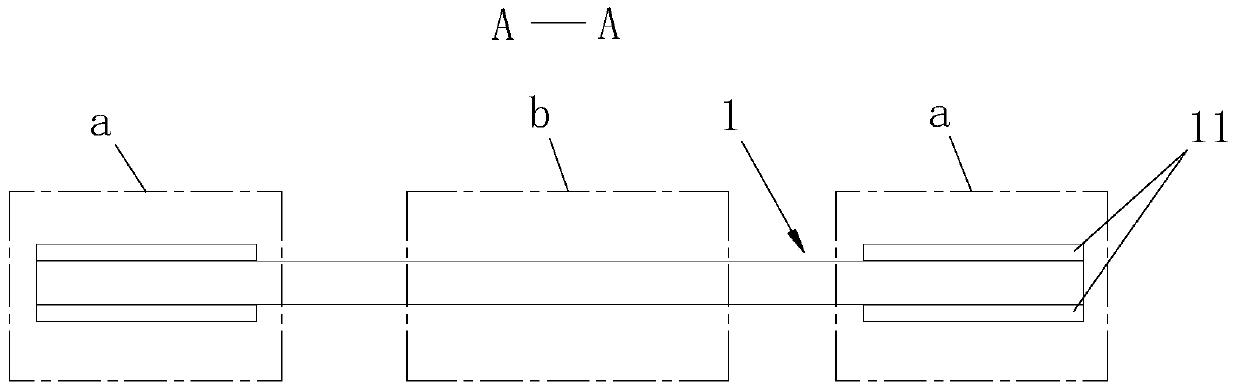

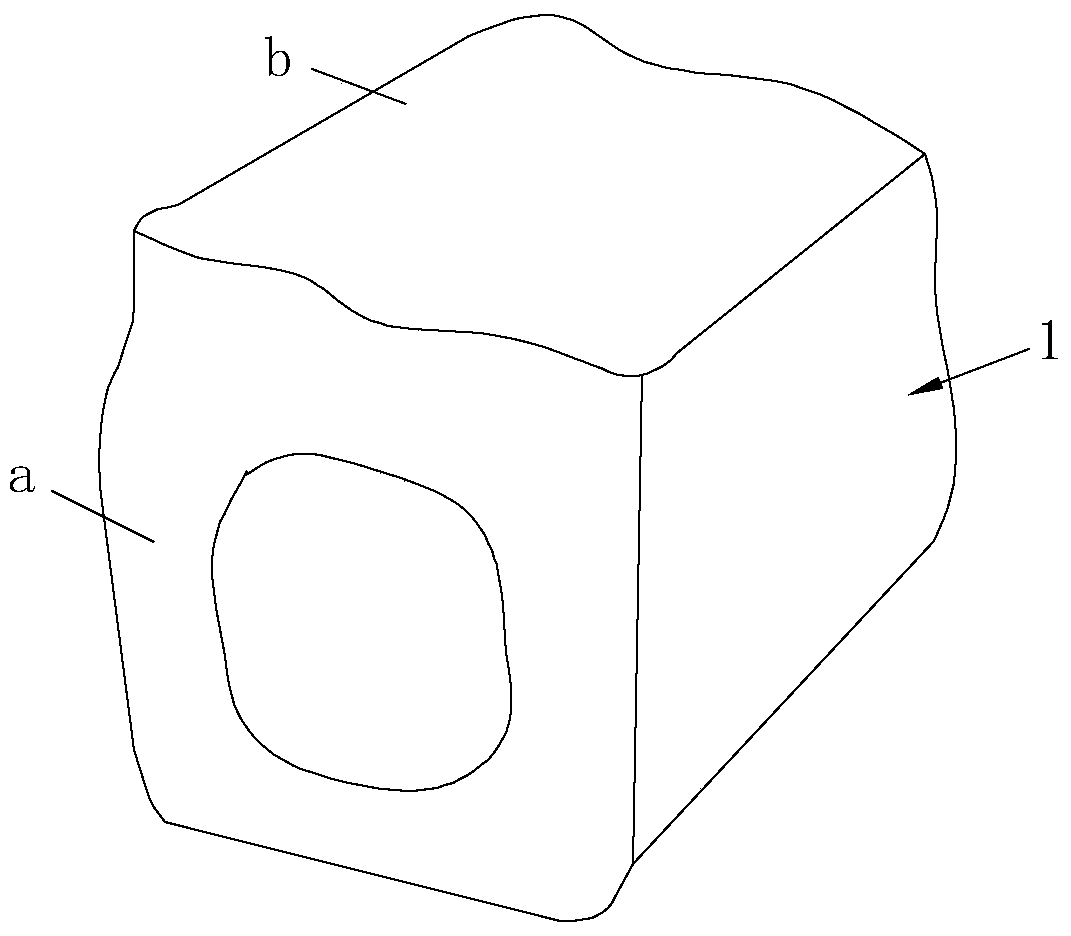

[0028] Embodiment one: if figure 1 , 2 As shown in , 3, this embodiment includes a strip-shaped shrink film body 1, the shrink film body 1 is provided with a shrinking bulls-eye forming area a, and the shrink sealing area a has two areas, and the two areas are respectively located on two symmetrical sides in the length direction , and at the edge of the side. At the same time, a protective coating 11 is coated on the front and back sides of the shrinking bull's-eye forming area a, the protective coating 11 is varnish, and the coated thickness of the protective coating 11 is 0.01mm. Among them, the varnish is a common consumable on the market. In addition to using varnishes directly available on the market, one of acrylic, polyamide, polyurethane, chlorinated polypropylene, or a combination of them can also be used. Of course, in addition to varnish, one of gold-adjusting oil, silicone oil, ink containing chlorinated polypropylene, ink containing polyurethane, and ink contai...

Embodiment 2

[0034] Embodiment 2: Compared with Embodiment 1, the difference is that the protective coating is only applied to the front side of the shrinking bull's-eye forming area a. It is found in actual operation that the shrink film body 1 coated with a protective coating on the front side only has a 60% probability of no scarring during the shrink molding process. Wherein, the so-called front side means that when the shrink film body 1 is wrapped around the product, the side facing the outside of the shrink film body 1 is the front side; otherwise, it is the reverse side.

Embodiment 3

[0035] Embodiment 3: Compared with Embodiment 1, the difference is that the protective coating is only applied to the reverse side of the shrinking bull's-eye forming area a. It has been found in actual operation that the shrink film body 1 coated with a protective coating on the front only has a probability of no scarring of 40% during the shrink molding process.

[0036] In the present invention, the shrinking bull's-eye molding area a can be only the front side, or only the back side, or both the front and back sides, and a protective coating 11 is coated on the shrinking bull's-eye molding area a, and the protective coating 11 is One of varnish, gilding oil, lubricating oil, silicone oil, ink containing chlorinated polypropylene, ink containing polyurethane, ink containing polyamide, or multiple combinations. Because the shrink film has heat-sealing properties, when the heat shrink machine heats the shrink bull’s-eye forming area a, the shrink bull-eye forming area a will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com