Solution Of Aromatic Polyamide For Producing Display Element, Optical Element, Illumination Element Or Sensor Element

A technology of aromatic polyamide and polyamide, applied in polyamide coatings, electrical components, electric solid devices, etc., can solve problems such as heat resistance reduction, heat resistance and mechanical strength problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

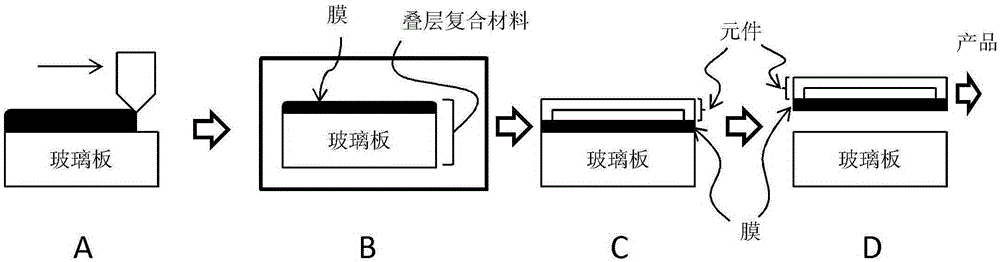

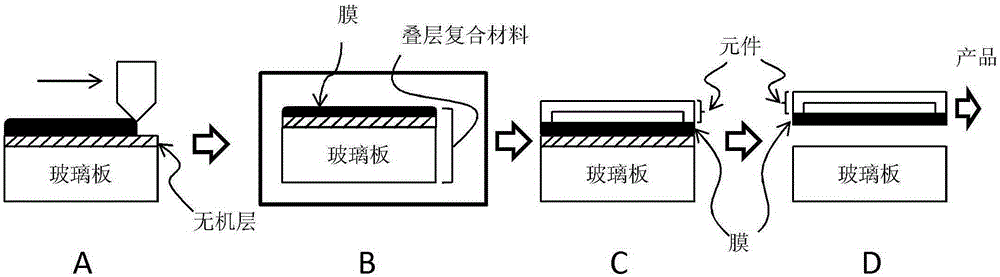

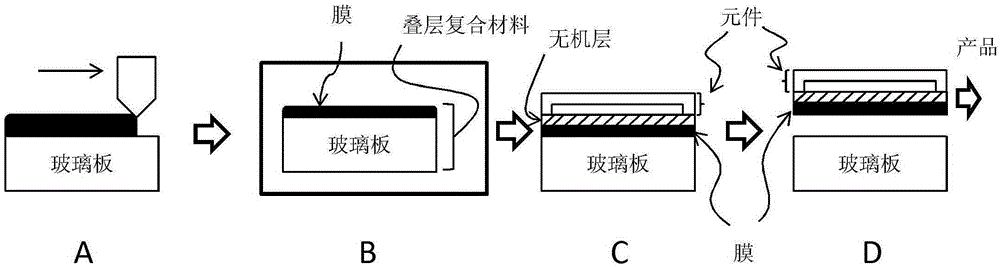

[0014] It is often used in display elements such as organic EL (OEL) or organic light emitting diode (OLED), optical elements, or lighting elements figure 1 Manufactured by the process shown. In short, the polymer solution (varnish) is coated on the glass support material or the silicon wafer support material (process A); the coated polymer solution is cured to form a film (process B); the OLED and other components are formed on the above-mentioned film (process C); after that, elements (products) such as OLEDs are peeled off from the above-mentioned supporting material (process D). In recent years, polyimide films have been used as figure 1 The process of film use.

[0015] In addition, sensor elements used in input devices such as imaging devices are often used figure 1 Manufactured by the process shown. That is, a polymer solution (varnish) is applied to a support material (glass or silicon wafer) (process A); the applied polymer solution is cured to form a film (proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com