Regenerative PETG/PC alloy light diffusion material and preparation method thereof

A light diffusion and light diffusion agent technology, which is applied in the field of recycled PETG/PC alloy light diffusion materials and its preparation, can solve the problems of high price and pitted application, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

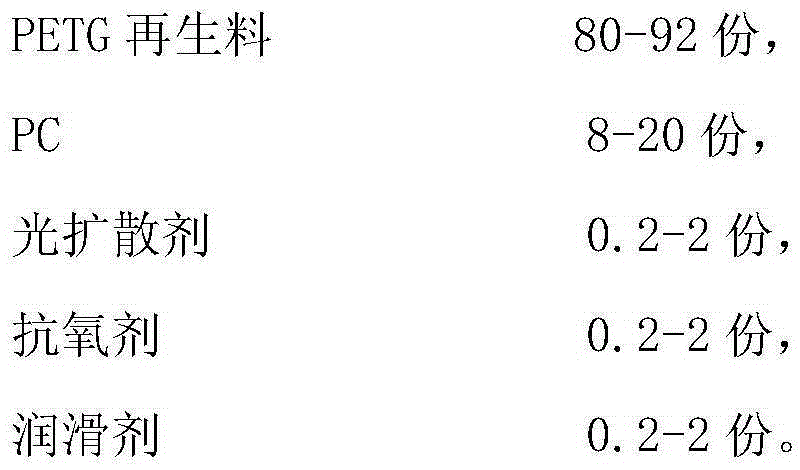

[0022] A kind of regeneration PETG / PC alloy light diffusion material, comprises following raw material by weight part:

[0023]

[0024] The antioxidant is compounded by antioxidant 1010 and antioxidant 168 with a mass ratio of 1:2.

[0025] The preparation method of the above-mentioned regenerated PETG / PC alloy light diffusion material comprises the following steps:

[0026] (1) Add each raw material to a mixer and mix at a stirring speed of 300 Hz. After 3 minutes, discharge to obtain a mixture;

[0027] (2) Put the mixture into a twin-screw extruder, melt and extrude it, and granulate it to obtain the product; the speed of the main machine is 28Hz, the feeding frequency is 14Hz, and the temperature of each section of the extruder is: Section I 120°C, Section II is 150°C, Section III is 170°C, Section IV is 170°C, Section V is 170°C, Section VI is 180°C, Section VII is 180°C, Section VIII is 180°C, Section IX is 180°C, and the head temperature is 190°C.

[0028] The twi...

Embodiment 2

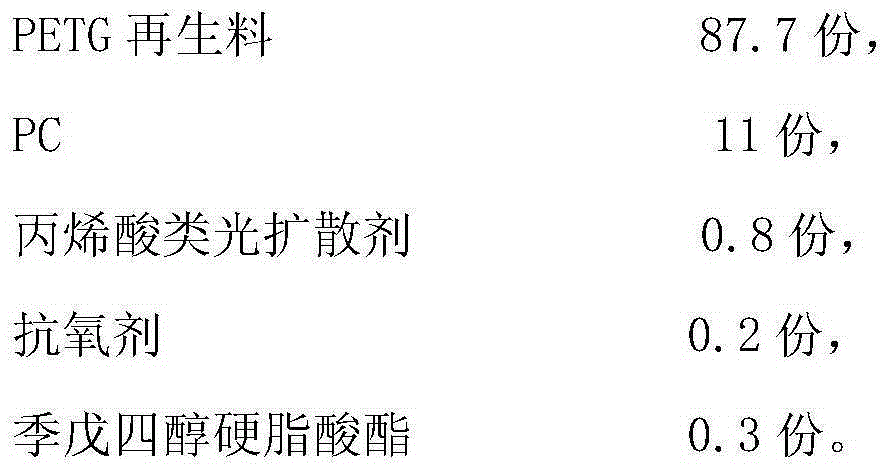

[0030] A kind of regeneration PETG / PC alloy light diffusion material, comprises following raw material by weight part:

[0031]

[0032] The preparation method is the same as in Example 1.

Embodiment 3

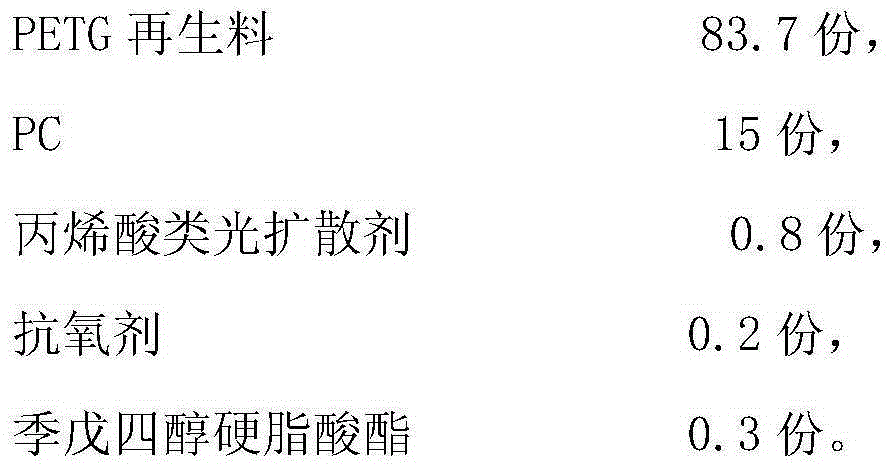

[0034] A kind of regeneration PETG / PC alloy light diffusion material, comprises following raw material by weight part:

[0035]

[0036] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com