Center oxygen lance for coal gasifier

A technology of coal gasification and oxygen blowing pipe, which is applied in the direction of gasification device feeding tools, manufacture of combustible gas, petroleum industry, etc. It can solve the problems of non-corrosion resistance, heavy quality, high surface temperature, etc., and achieve long maintenance-free service life , easy installation and maintenance, and the effect of reducing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

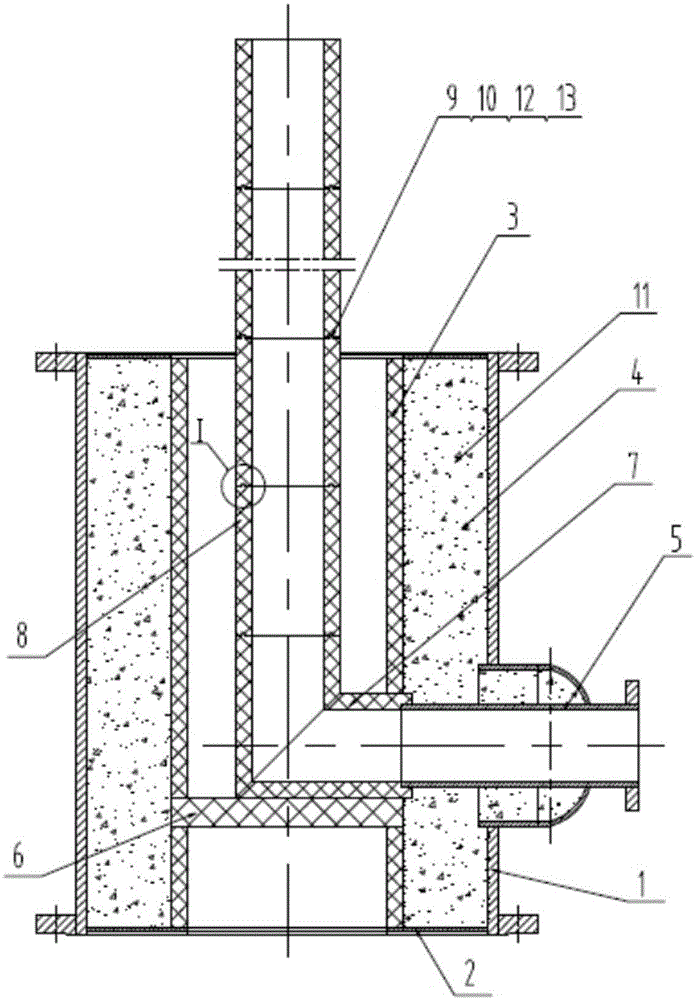

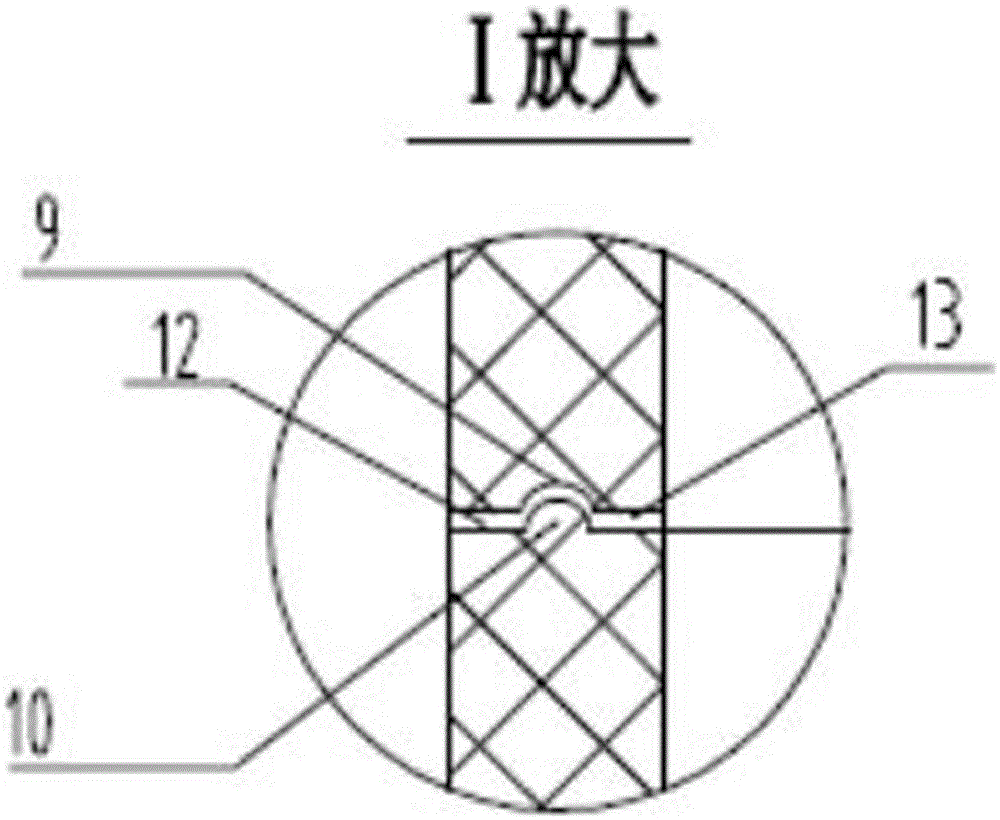

[0014] In conjunction with the description of specific embodiments: as figure 1 As shown, a central oxygen blowing pipe for a coal gasification furnace is characterized in that it includes a shell 1 of a cylindrical structure and a slag tunnel liner 3 lined therein, and a vertical oxygen blowing pipe 8 is arranged in the slag tunnel liner 3 The center extends out of the top of the shell 1, the elbow 7 is connected vertically to the vertical oxygen pipe 8, and the horizontal oxygen pipe 5 is connected to the elbow 7; an auxiliary support 6 is provided at the bottom of the elbow 7 to support the elbow 7 and the vertical oxygen blowing pipe 7. Pipe 8; a gap 11 is provided between the casing 1 and the slag tunnel liner 3, and the gap 11 is filled with a light-weight thermal insulation sealing material 4; the top and bottom of the casing 1 and the slag tunnel liner 3 are respectively connected with retaining rings 2.

[0015] The vertical oxygen blowing pipe 8 of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com