Energy-saving and emission-reduction particle elution machine

A technology of energy saving, emission reduction, and washing machine, which is applied to other washing machines, washing devices, textiles and paper making, etc. It can solve problems such as large water consumption and waste of water resources in the research and development stage, and achieve high cleaning efficiency and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

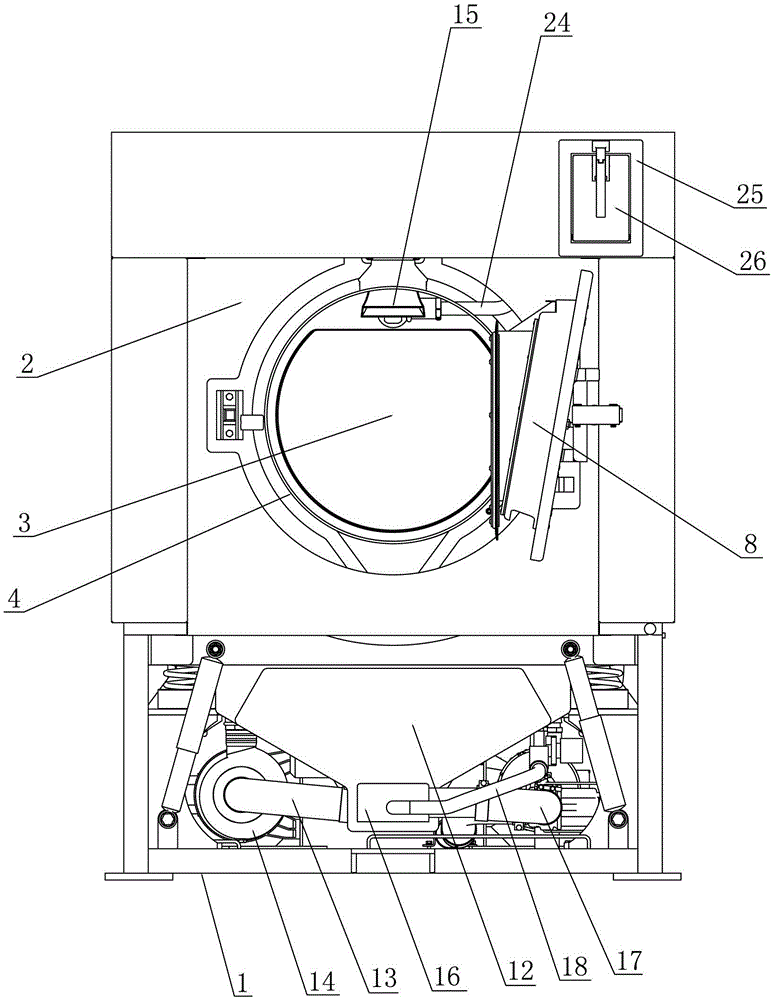

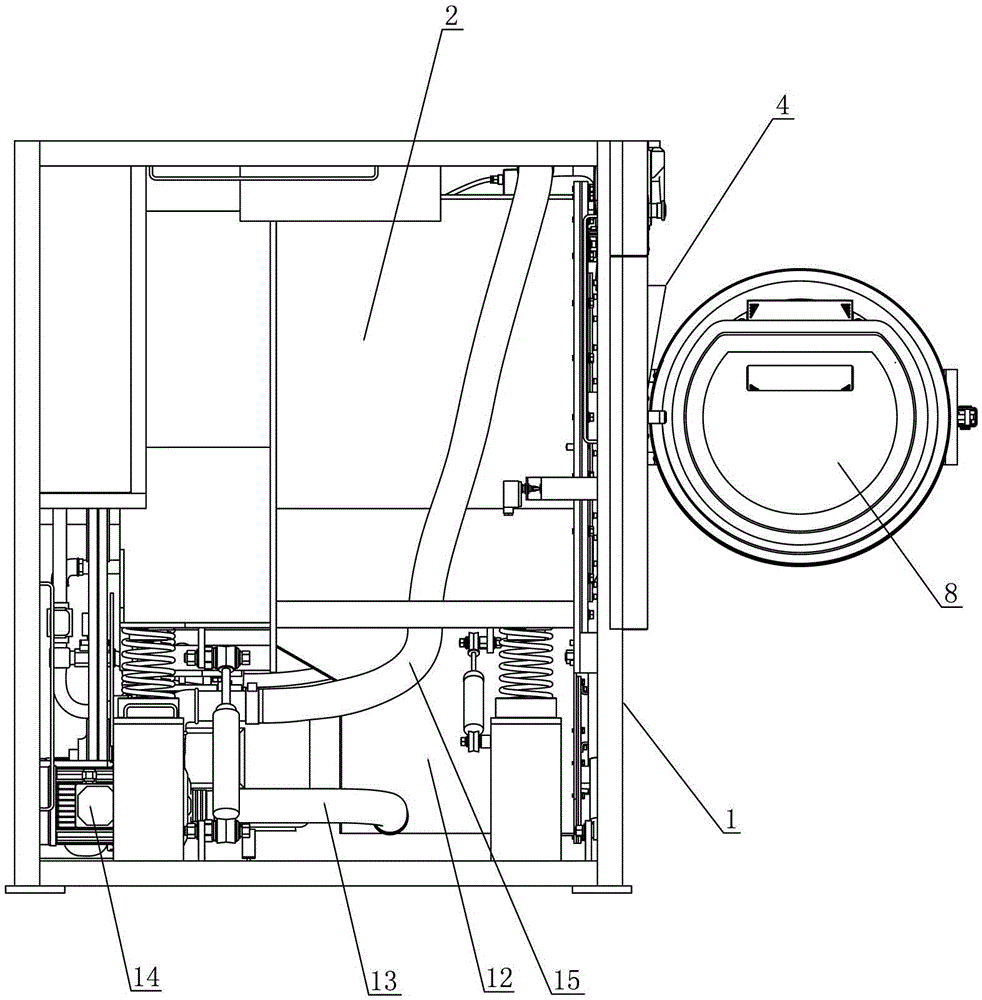

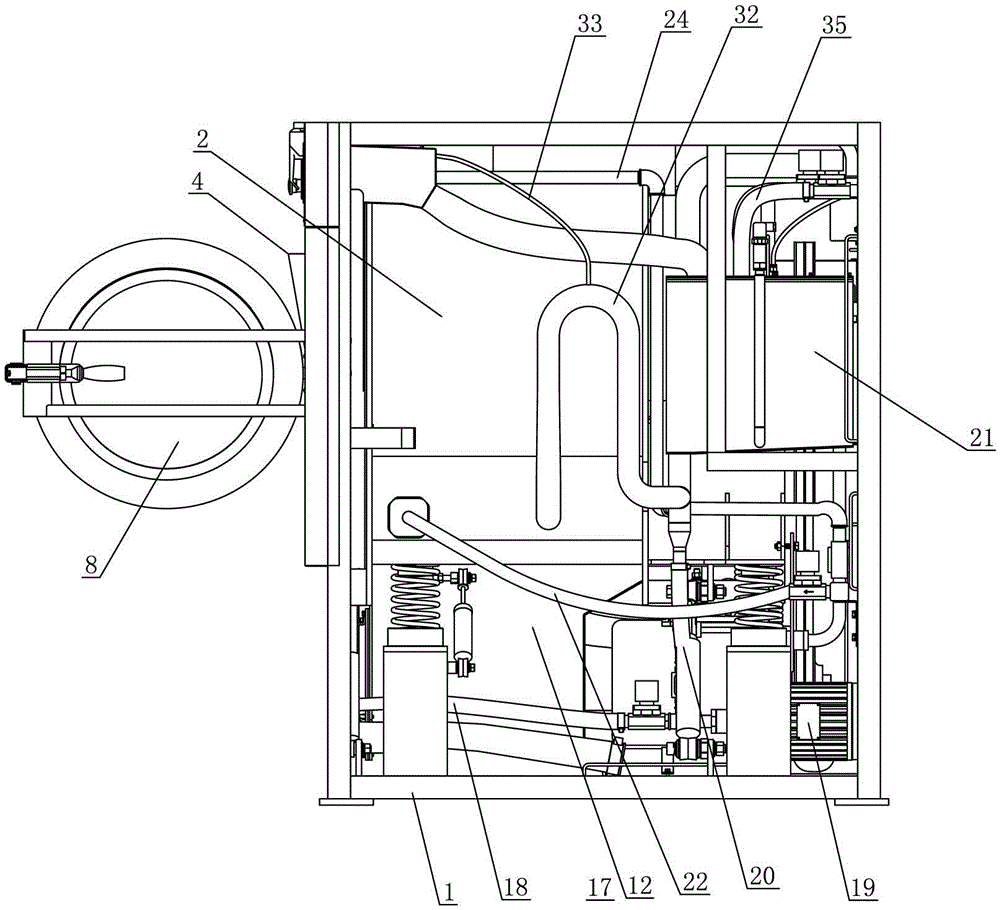

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, the energy-saving and emission-reducing particulate washing machine includes: a frame 1, a washing tub 2 arranged in the frame 1, a drum 3 arranged in the washing tub 2, and a drive for driving the rotation of the drum 3 Assemblies, a feeding port is provided on the washing tub 2 in front of the feeding port of the drum 3, an annular end cover 4 is provided outward at the feeding port of the washing tub 2, and a compound is provided on the top of the end cover 4 The spray hole 5 and the water spray hole 6 are provided with the end cover liquid outlet 7 communicating with the inside of the washing bucket 2 at the bottom of the end cover 4, and the rack 1 on the side of the end cover 4 is provided with a washing bucket that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com