Leveling agent for leather, preparation method and method for dyeing leather

A leveling agent and leather technology, applied in the field of leather auxiliaries, can solve the problems of non-obvious difference, different density, thickness, fiber structure, uneven dyeing of leather, etc., achieve uniform dyeing effect, simple preparation method, and improve The effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The leather leveling agent of the present embodiment comprises the following components by weight: 30 parts of dodecylamine polyoxyethylene ether, 20 parts of dodecyl dimethyl benzyl ammonium chloride, C 16 20 parts of fatty alcohol polyoxyethylene ether, 1 part of polyvinylpyrrolidone, 19 parts of ethylene glycol, and 10 parts of water.

[0036] Mix the above ingredients at 50°C and stir at 800r / min for 20min to prepare leveling agent 1. After testing, pH=7.5.

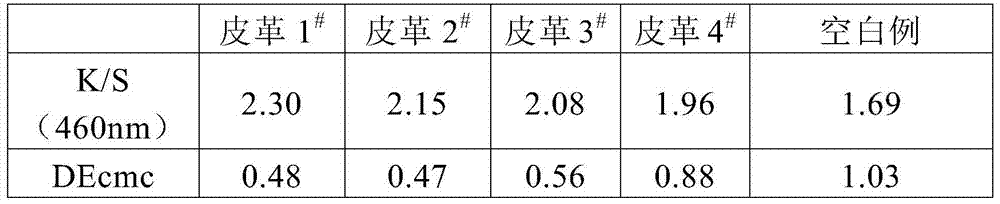

[0037] Put 520g of water-washed bovine leather into the drum, after neutralization and washing, add 1040g of water, add 2.6g of leveling agent 1 into the drum, and rotate for 5min at 50°C. Add 5.2g dyestuff subsequently, after rotating 60min, add formic acid to fix the color, wash with water, dry, obtain dyed leather 1 # .

Embodiment 2

[0039] The leather leveling agent of the present embodiment includes the following components by weight: 40 parts of stearylamine polyoxyethylene ether, 15 parts of dodecyl dimethyl benzyl ammonium chloride, C 18 15 parts of fatty alcohol polyoxyethylene ether, 5 parts of polyvinylpyrrolidone, 15 parts of ethylene glycol, and 10 parts of water.

[0040] Mix the above ingredients at 40°C and stir at 1000r / min for 15min to prepare leveling agent 2. After testing, pH=7.8.

[0041]Put 540g of water-washed bovine leather into the drum, after neutralization and washing, add 1080g of water, add 2.7g of leveling agent 2 into the drum, and rotate at 40°C for 10min. After adding 5.4g of dyestuff and rotating for 50min, add formic acid to fix the color, wash with water, and dry to obtain dyed leather 2 # .

Embodiment 3

[0043] The leveling agent for leather of the present embodiment includes the following components by weight: 15 parts of cocoamine polyoxyethylene ether, 10 parts of laurylamine polyoxyethylene ether, 10 parts of dodecyl dimethyl benzyl ammonium chloride, C 14 Fatty alcohol polyoxyethylene ether 5 parts, C 18 10 parts of fatty alcohol polyoxyethylene ether, 2.5 parts of polyvinylpyrrolidone, 12.5 parts of ethylene glycol, and 13 parts of water.

[0044] Mix the above ingredients at 55°C and stir at 600r / min for 15min to prepare leveling agent 3. After testing, pH=7.2

[0045] Put 500g of water-washed bovine leather into the drum, after neutralization and washing, add 1000g of water, add 2.5g of leveling agent 3 into the drum, and rotate for 3min at 40°C. After adding 5g of dyestuff and rotating for 40min, add formic acid to fix the color, wash with water, and dry to obtain dyed leather 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com