Vehicle frame, milling machine, and adjusting method for milling machine gravity center

A technology for adjusting the center of gravity and a milling machine, which is applied in the field of adjusting the center of gravity of the milling machine, the frame and the milling machine, can solve the problems such as the unstable turning of the whole milling machine, and achieves high construction efficiency, precise adjustment, and improved The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

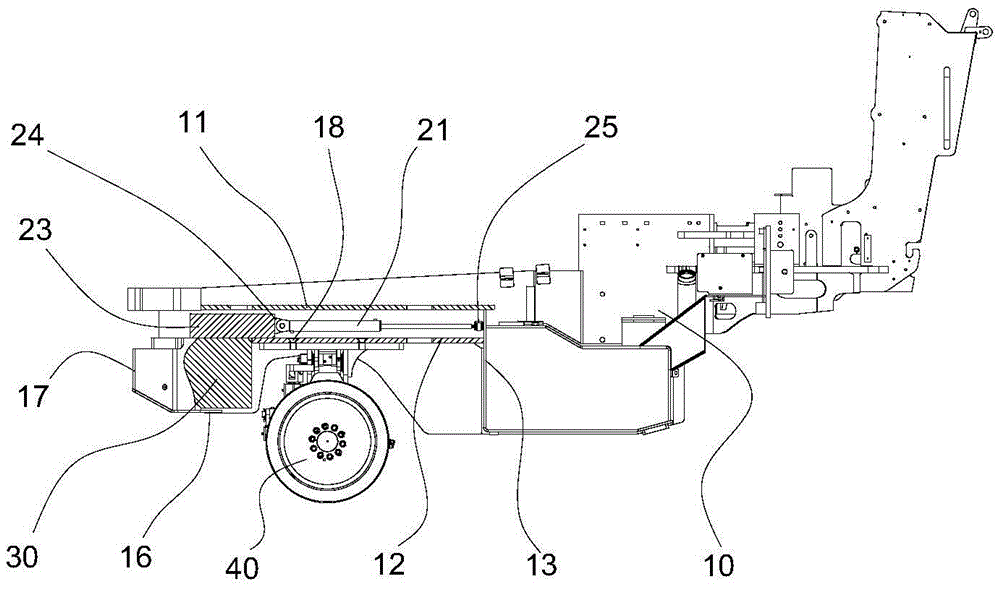

[0045] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

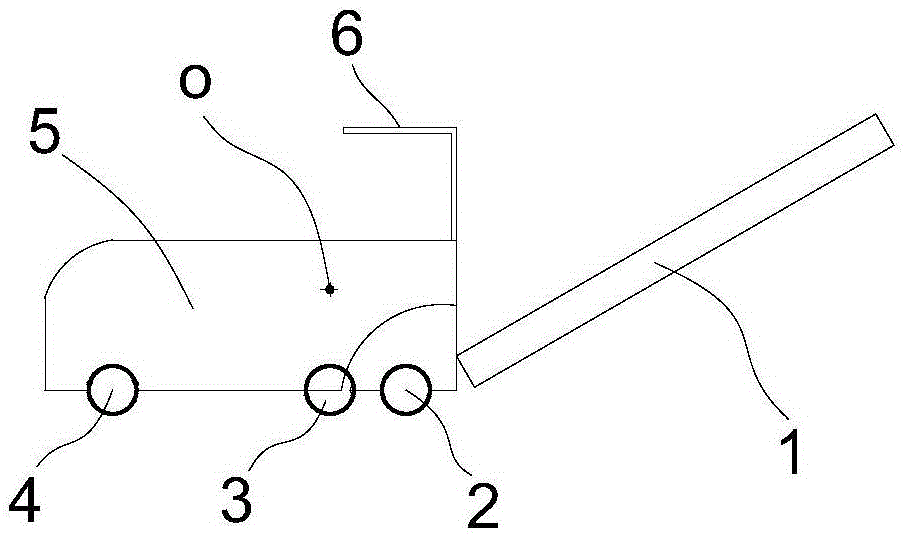

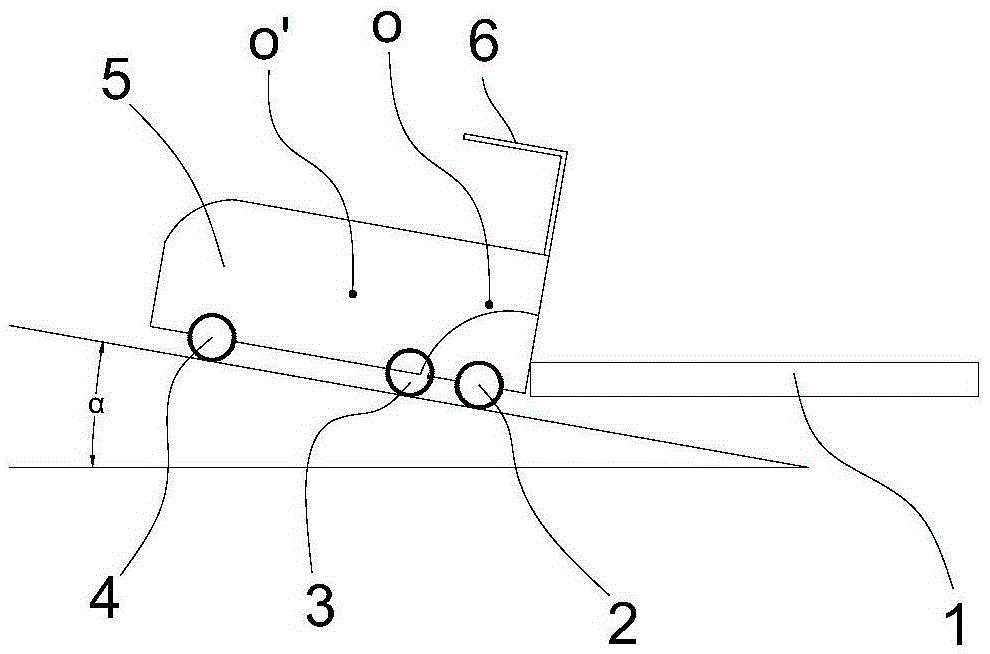

[0046] A milling machine as a road construction machine generally includes a milling machine body 100, a milling drum 300, and a feeder 200; machine, etc.), the milling machine body 100 provides power and motion for the milling drum 300 and the feeder 200, and controls the milling drum 300 and the feeder 200.

[0047] It should be noted that the definition of the traveling direction of the milling machine as front, rear, left and right is based on the forward direction of the milling machine.

[0048] The vehicle frame disclosed in the present invention can be used as the vehicle frame of various engineering machines, and the vehicle frame of the present invention will be described below only by taking a milling machine as an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com