Unit panel for spherical shape building and its application method

A unit panel and construction technology, applied to the processing of building materials, construction, building components, etc., can solve the problems of high labor and material costs, troublesome trapezoidal straight panel processing, and complicated spherical panel molding, so as to achieve simple structure and improve stability. And safety, waterproof, reliable and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

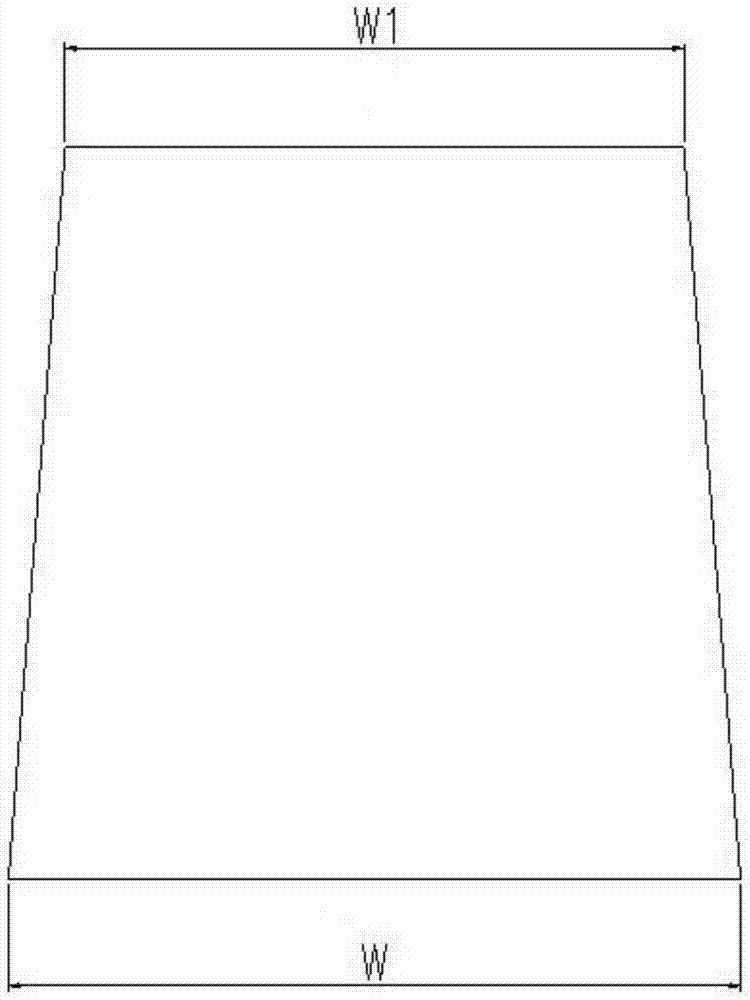

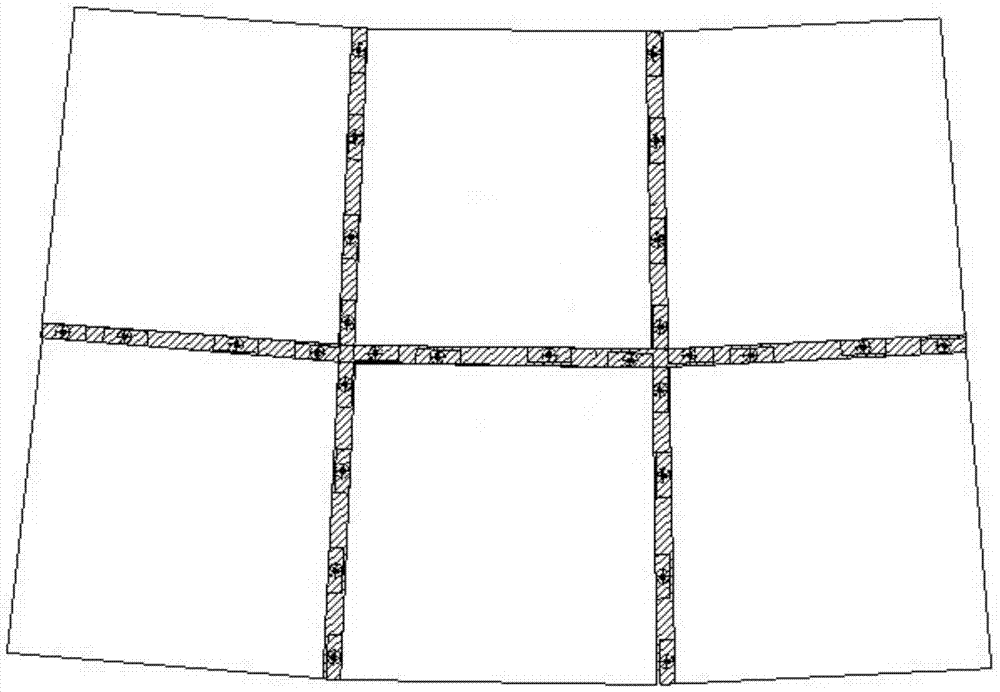

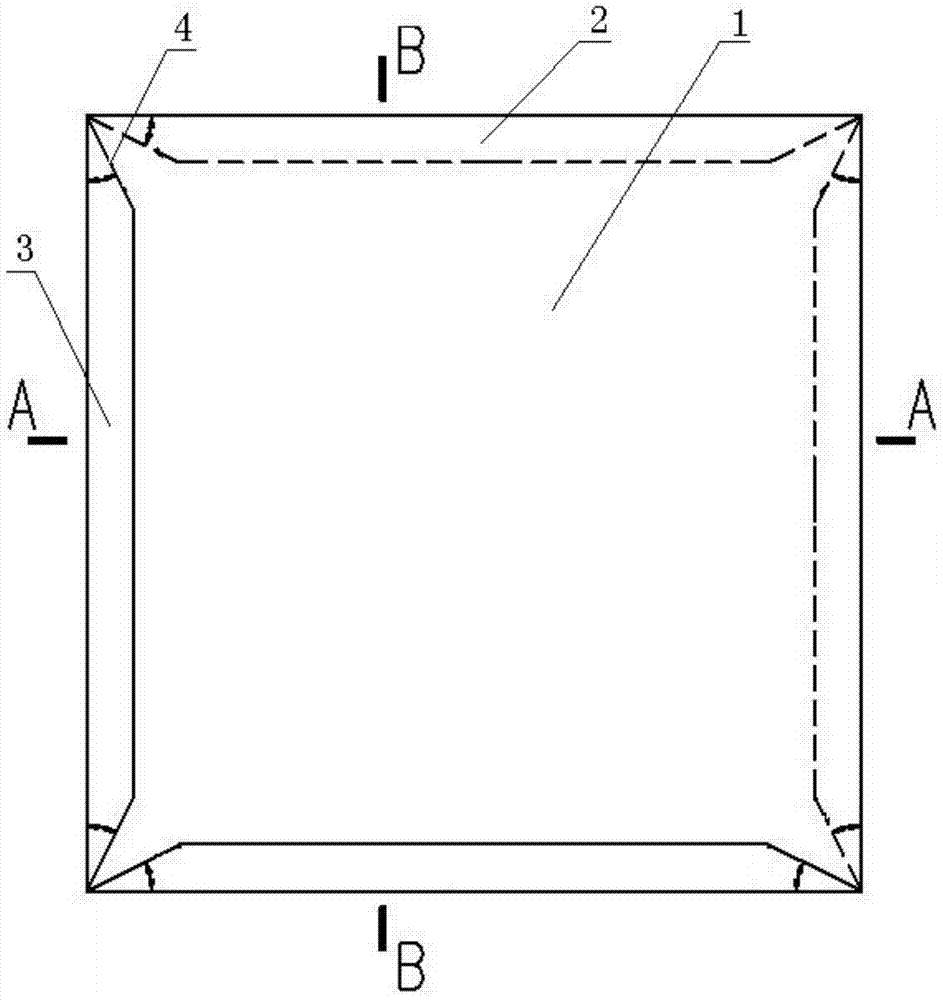

[0022] Such as Figure 3-6 As shown, a unit panel for a spherical shape building includes a rectangular panel 1, wherein two adjacent edges of the rectangular panel 1 are respectively provided with inwardly turned inner folds 2 along a direction perpendicular to the rectangular panel 1, and the other two Edges perpendicular to the direction of the rectangular plate 1 are respectively provided with outwardly turned outward flanges 3, the angles formed by the inner flange 2, the outer flange 3 and the rectangular plate 1 are all 50°, and the inner flange 2, The width of the outer flange 3 is 10 mm, the angles formed by the inner flange 2, the outer flange 3 and the rectangular plate 1 and the width of the fold are consistent, and the inner flange 2 and the outer flange 3 are occluded when the rectangular plate 1 is spliced. The snap-on connection is secure.

[0023] Further, chamfers 4 are respectively provided at both ends of the inner folds 2 and the outer folds 3 to prevent ...

Embodiment 2

[0029] Such as Figure 3-6 As shown, a unit panel for a spherical shape building includes a rectangular panel 1, wherein two adjacent edges of the rectangular panel 1 are respectively provided with inwardly turned inner folds 2 along a direction perpendicular to the rectangular panel 1, and the other two Edges are perpendicular to the rectangular plate

[0030] 1 direction is respectively provided with the outer flange 3 turned outwards, the included angles formed by the inner flange 2, the outer flange 3 and the rectangular plate 1 are all 60°, the inner flange 2, the outer flange 3 The width is 15mm, the inner fold 2, the outer fold 3 are formed with the rectangular plate 1

[0031] The included angles and the widths of the folds are consistent, and the inner fold 2 and the outer fold 3 of the rectangular plate 1 are fastened and fastened firmly when spliced.

[0032] Further, chamfers 4 are respectively provided at both ends of the inner folds 2 and the outer folds 3 to a...

Embodiment 3

[0040] Such as Figure 3-6 As shown, a unit panel for a spherical shape building includes a rectangular panel 1, wherein two adjacent edges of the rectangular panel 1 are respectively provided with inwardly turned inner folds 2 along a direction perpendicular to the rectangular panel 1, and the other two Edges perpendicular to the direction of the rectangular plate 1 are respectively provided with outwardly turned outward flanges 3, the angles formed by the inner flange 2, the outer flange 3 and the rectangular plate 1 are all 70°, and the inner flange 2, The width of the outer flange 3 is 20mm, the angles formed by the inner flange 2, the outer flange 3 and the rectangular plate 1 and the width of the fold are consistent, and the inner flange 2 and the outer flange 3 are occluded when the rectangular plate 1 is spliced. The snap-on connection is secure.

[0041] Further, chamfers 4 are respectively provided at both ends of each inner flange 2 and outer flange 3 to avoid conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com