Pressure water-storage device sealing structure

A technology of water storage device and sealing structure, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor air tightness, difficult screws, gas leakage in the water storage tank, etc., and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

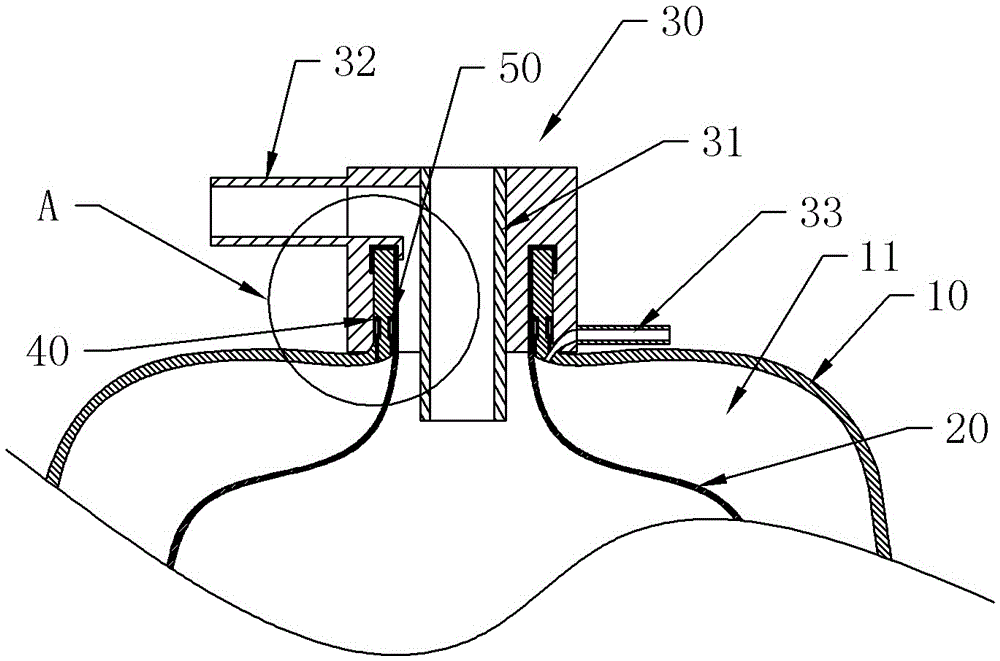

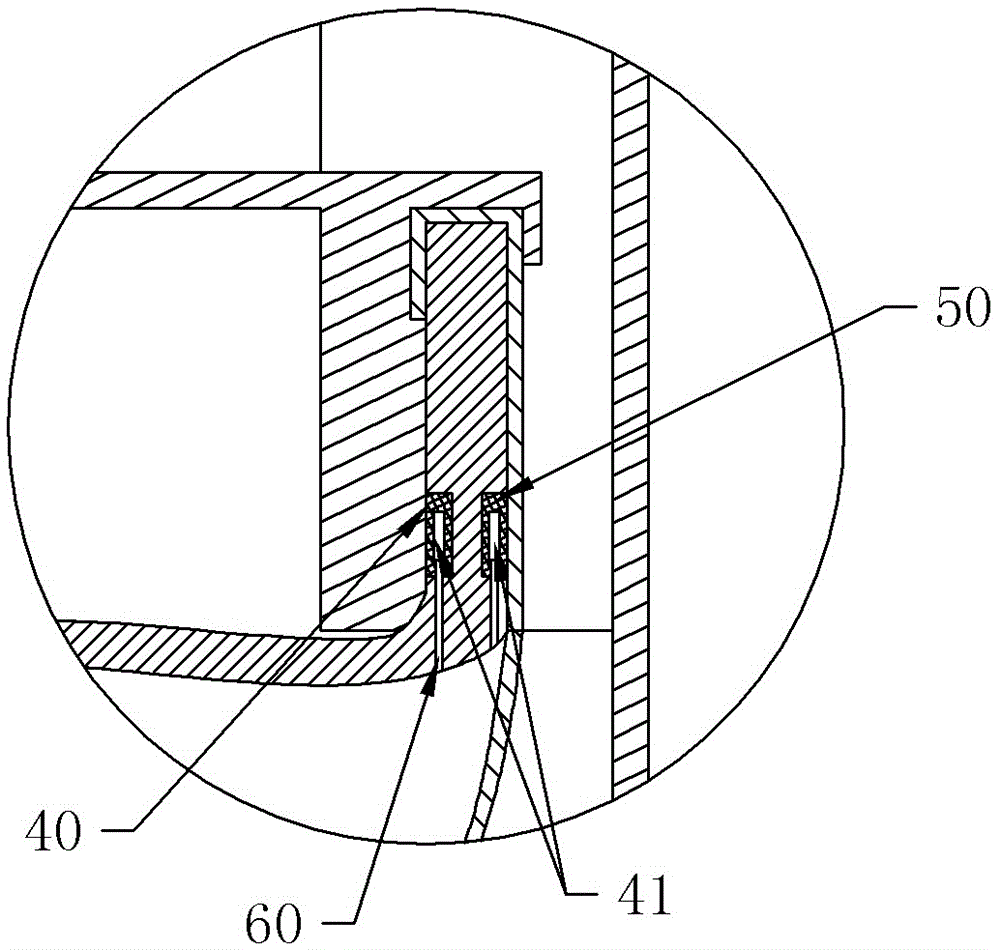

[0019] Embodiment 1 is basically as attached figure 1 and figure 2 Shown: a sealing structure of a pressure water storage device, including an outer shell 10, an elastic inner tank 20 and a pipe joint body 30, the elastic inner tank 20 is located in the outer shell 10, an air-filled cavity 11 is formed between the two, and the upper end of the outer shell 10 is provided with an opening , the upper end of the elastic liner 20 is provided with a water outlet, and the water outlet is located in the opening; the pipe joint body 30 is provided with a water inlet channel 31, a water outlet channel 32 and an inflation port 33, and the water inlet channel 31 and the water outlet channel 32 are all connected to the water outlet Connected, the pipe joint body 30 is connected to the upper end of the shell 10, and the elastic liner 20 is pressed on the upper end of the shell 10, the outer edge of the upper end of the shell 10 is provided with a first annular groove, and a first sealing r...

Embodiment 2

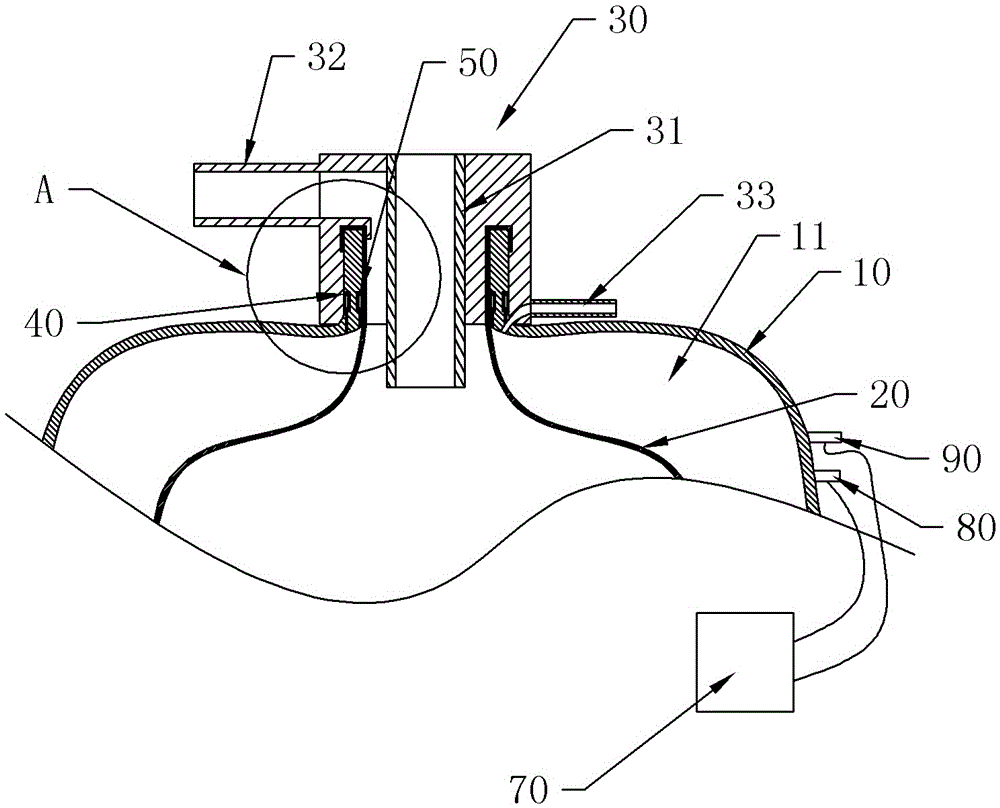

[0023] Such as image 3 As shown, the difference from Embodiment 1 is that this embodiment also includes a controller 70, an audible and visual alarm 80, and a pressure sensor 90 for detecting the pressure in the air chamber 11, and the pressure sensor 90 and the audible and visual alarm 80 Both are electrically connected to the controller 70 . The pressure sensor 90 can detect the pressure in the inflatable chamber 11 in real time. When the compressed gas in the inflatable chamber 11 leaks, when the water storage device drains, the pressure of the drain becomes smaller, thereby causing the drainage process to be affected; in the same state (such as water injection) completion or after the drainage is completed), the pressure sensor 90 detects that the pressure in the inflatable cavity 11 becomes smaller, and then transmits the signal to the controller 70, and the controller 70 controls the external inflatable device to inflate the inflatable port 33 to ensure water storage n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com