Anticorrosive treatment method based on flange and anticorrosive sealing structure

A technology of anti-corrosion treatment and flange, which is applied in the direction of flange connection, pipe/pipe joint/fitting, passing components, etc. It can solve the problems of anti-rust paint falling off, butter is not temperature-resistant, and anti-rust paint cannot be attached stably, etc., to achieve Good adhesion and sealing, ensuring firmness and durability, and ensuring the effect of anti-corrosion and sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example

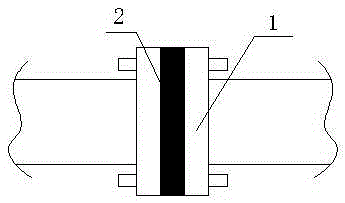

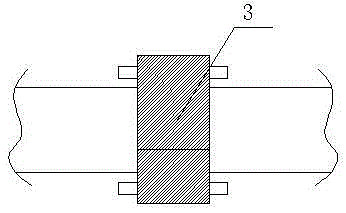

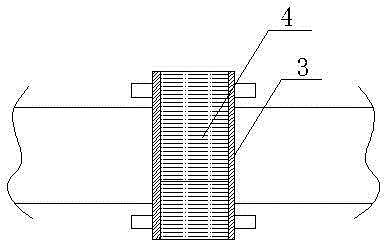

[0033] like Figure 1-3 As shown, this embodiment provides a flange-based anti-corrosion treatment method, which adopts three unit structures: anti-corrosion unit, anti-corrosion tape unit, and outer protective tape unit. By organically combining the three units into an integral structure The complete anti-corrosion structure is used to solve the problems existing in the technical solutions for flange anti-corrosion treatment in the prior art.

[0034] This embodiment mainly includes three steps, respectively corresponding to the above three unit structures, as follows:

[0035] 1. The steps of injecting anti-corrosion sealant into the middle seam of the flange

[0036] The anti-corrosion sealant is a flexible sealant that never cures and does not flow at high temperatures. Before injecting the anti-corrosion sealant, first remove the floating rust and dross in the middle seam of the flange with a wire brush and other tools, and then use a transparent adhes...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap