Organic silicon light-cured packaging glue used for LED packaging and application

A technology of LED encapsulation and light curing, which is applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of poor reliability, low efficiency, and low light output rate of products, and achieve good adhesion and sealing and curing speed Fast, the effect of improving the light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

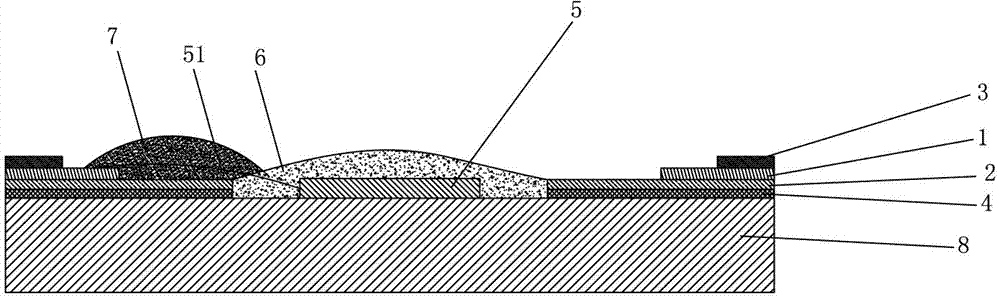

[0031] The organic silicon photocurable encapsulant for LED packaging proposed by the present invention includes photocurable silicone resin, methoxy polyethylene glycol monoacrylate, polyether modified organosiloxane, silicon dioxide modified silicone alkanes, 2-hydroxy-2-methyl-1-phenylacetone, 1-hydroxy-cyclohexylbenzophenone, urethane monoacrylate, hexanediol acrylate and phenol. The weight percentage of each substance is: 40-80% of photocurable silicone resin, 20-40% of methoxy polyethylene glycol monoacrylate, 0.5-1.5% of polyether modified organosiloxane, and 0.5-1.5% of polyether modified silicone Alkanes 0.3-0.9%, 2-hydroxy-2-methyl-1-phenylacetone 1-6%, 1-hydroxy-cyclohexylbenzophenone 1-6%, urethane monoacrylate 1-5% , Hexylene glycol acrylate 0.3-2.0%, phenol 0.01-1%. Among them, photocurable silicone resin is the main photocurable silicone resin, which is the main photocurable film-forming substance; methoxy polyethylene glycol monoacrylate is used as photocurabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap